Portable ultra-long tubular belt conveyor

A tubular belt conveyor technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of insufficient distance for conveying materials, achieve convenient loading and unloading, long service life, and reduce dust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

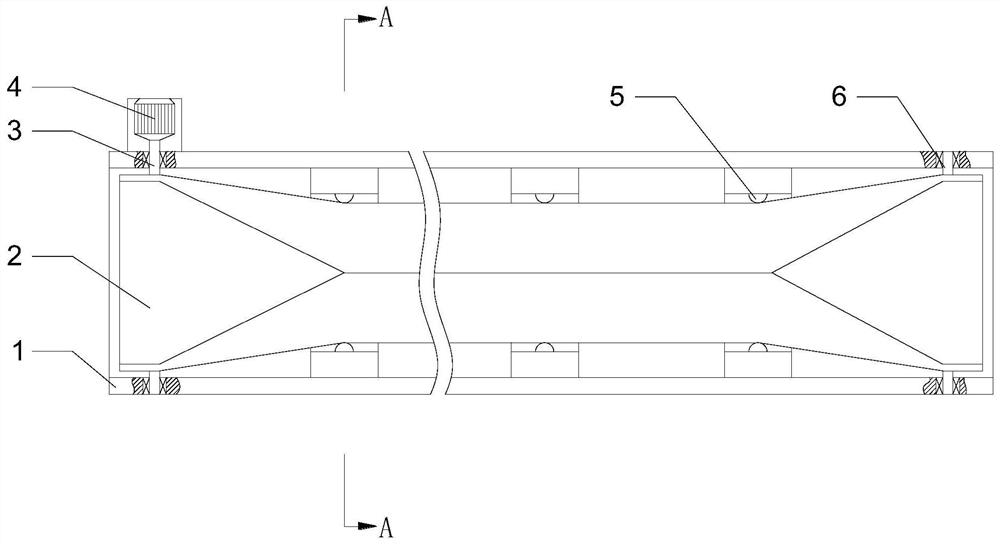

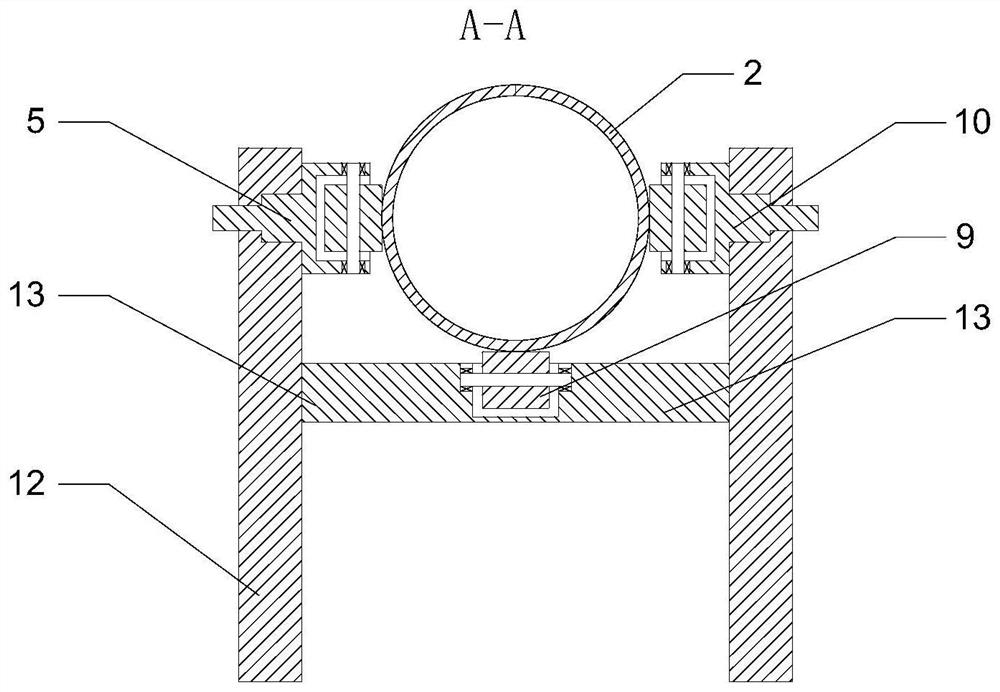

[0028] Such as Figure 1-6 As shown, a portable super long tubular belt conveyor comprises a truss 1, and the truss 1 includes a first vertical frame 12 and a second vertical frame 11 arranged oppositely, between the first vertical frame 12 and the second vertical frame 11 A horizontal frame 13 is installed, a driving shaft 3 and a driven shaft 6 are respectively installed between the first vertical frame 12 and the second vertical frame 11, the driving shaft 3 is equipped with a driving roller 7, and one end of the driving shaft 3 is equipped with a motor 4, A driven roller 8 is installed on the driven shaft 6, a conveyor belt 2 is installed between the driven roller 8 and the driving roller 7, a left rolling mechanism 5 is installed on the inside of the first vertical frame 12, and a Right rolling mechanism 10, lower rolling mechanism 9 is installed on the top surface of cross frame 13, leaving conveying cavity between left rolling mechanism 5, right rolling mechanism 10 and...

Embodiment 2

[0036] Such as Figure 1-6As shown, on the base layer of the above-mentioned embodiment, this embodiment provides a preferred structure that can reduce environmental pollution during the transportation of materials, that is, the middle part of the left roller 55, the middle part of the right roller 105 and the middle part of the lower roller 93 The connecting line between them is an equilateral triangle, and the distance between the left roller 55 and the right roller 105 is less than the width of the conveyor belt 2; the material of the conveyor belt 2 is rubber, and the first vertical frame 12 and the second vertical frame 11 are parallel to each other.

[0037] In this embodiment: when the conveying tape 2 passes between the left roller 55, the right roller 105 and the lower roller 93, the left roller 55 and the right roller 105 can bulge the two ends of the conveying tape 2, so that the conveying tape 2 is on the left roller. 55. The space between the right roller 105 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com