Ship stern thrust arrangement structure

A technology for arranging structures and ships, which is applied in the direction of ship propulsion, propulsion device engines, ship components, etc., can solve the problems such as difficult to find the tail shaft area, and achieve the effects of reducing the amount and cost of maintenance engineering, convenient maintenance, and good ventilation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

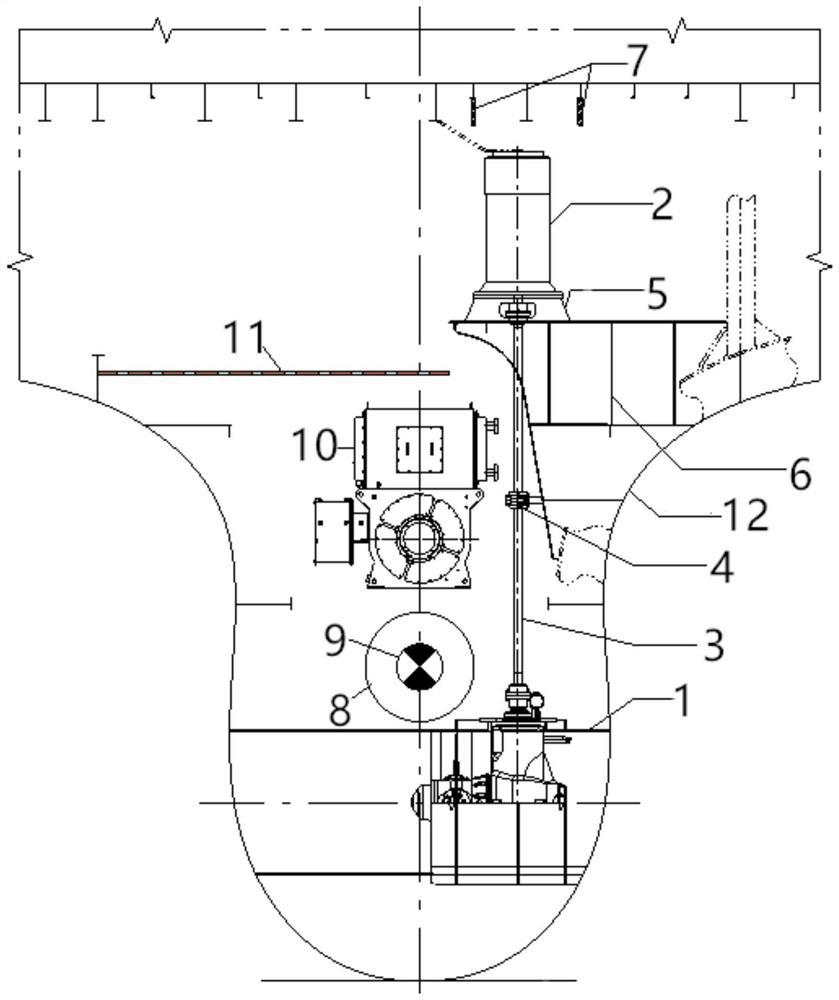

[0022] like figure 1 As shown, a ship stern thruster arrangement structure includes a drive motor 2 and a stern thruster body 1. The stern thruster body 1 is installed below the propulsion shafting, and the installation position of the drive motor 2 is higher than the shaft generator 10. The drive shaft 3 extending downward is connected to the output end of the motor 2. The drive shaft 3 will not occupy too much space, and will not interfere with or occupy the installation space of the shaft generator 10, coupling 8, propulsion shaft 9 and other equipment. , the lower end of the drive shaft 3 is in transmission connection with the tail side pusher body 1, and the drive motor 2 and the drive shaft 3 are coaxially arranged vertically. Adopting the above arrangement avoids the tail shaft area with narrow space and many equipments, and avoids the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com