Cooling structure of ultrasonic welding head

A cooling structure and ultrasonic technology, which is applied in the field of ultrasonic welding, can solve the problems that the temperature of the welding head is difficult to drop, the heat dissipation effect of the thicker part of the welding head is poor, and the hot air cannot be absorbed and cooled, so as to achieve the effect of easy cooling and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

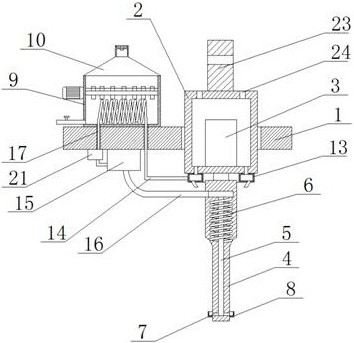

[0021] Example 1 as Figure 1-2 As shown, a cooling structure of an ultrasonic welding head includes a mounting seat 1, an organic casing 2 is installed on the mounting seat 1, a transducer 3 is installed in the casing 2, a welding head 4 is installed at the bottom of the transducer 3, and a welding head 4 is installed on the bottom of the transducer 3. There is a T-shaped gas transmission channel 5 in the head 4, and a spiral heat dissipation channel 6 is opened in the welding head 4. Both ends of the heat dissipation channel 6 are connected with the gas transmission channel 5, and the gas transmission channel 5 is circular and uniform. There are a number of air injection holes 7 at the distance between them. The welding head 4 located below the air injection holes 7 is fixedly sleeved with a diversion cover 8. The upper end of the mounting base 1 is fixedly connected with a cooling box 9, and the upper opening of the cooling box 9 is connected to a row. Gas hood 10, exhaust ...

Embodiment 2

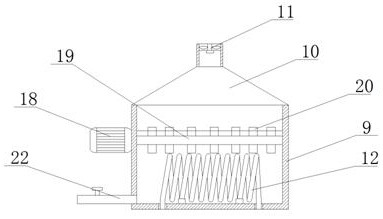

[0022] Embodiment 2 is on the basis of embodiment 1 such as Figure 1-2 As shown, a motor 18 is installed on the wall of the cooling box 9, and the output end of the motor 18 is connected with a rotating rod 19 through a coupling. Several rotating plates 20 are fixedly connected to the wall of the rotating rod 19. When the welding head 4 is cooling, the motor 18 is started to drive the rotating rod 19 and the rotating plate 20 to rotate, so that the rotating plate 20 beats the liquid surface of the cooling liquid to speed up cooling. The cooling speed of the liquid is improved, and the use time of the cooling liquid is prolonged.

Embodiment 3

[0023] Embodiment 3 is such as on the basis of embodiment 1 figure 1 As shown, a drying box 21 is connected to the wall of the gas outlet pipe 17, and the drying box 21 is fixedly connected to the bottom of the mounting base 1. The drying box 21 is filled with a desiccant, which can dry the gas passing through the bellows 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com