Tea processing method of tea processing device for enzyme deactivation by microwave heating

A processing method and microwave heating technology, applied in the direction of tea processing before extraction, etc., can solve the problems of poor heating, uneven heating of tea leaves, and inability to achieve horizontal flattening of tea leaves, and achieve the effect of uniform heating and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

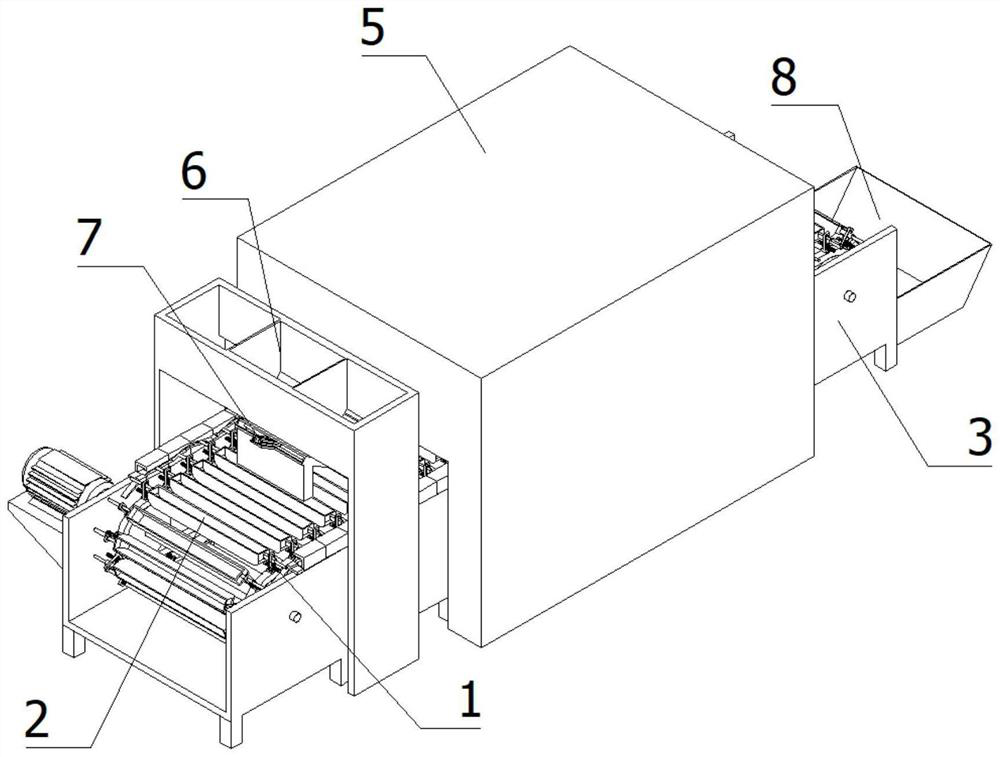

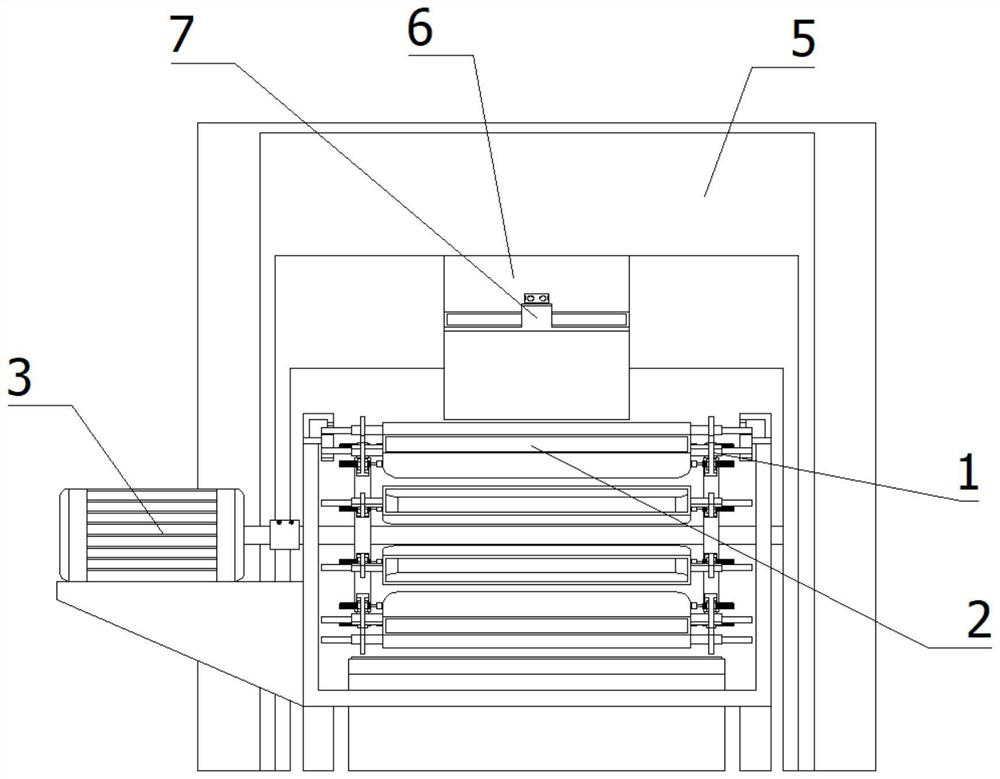

[0039] Such as Figure 1-11 As shown, a tea processing device through microwave heating and greening includes a frame 10, a transmission mechanism 3 arranged on the frame 10 for transporting tea leaves, and a transmission mechanism arranged on the frame 10 and located in the transmission path of the transmission mechanism 3. The microwave heating mechanism 5 used for heating the tea leaves on the transport mechanism 3 can realize the greening of the tea leaves through the heating of the microwave heating mechanism 5 .

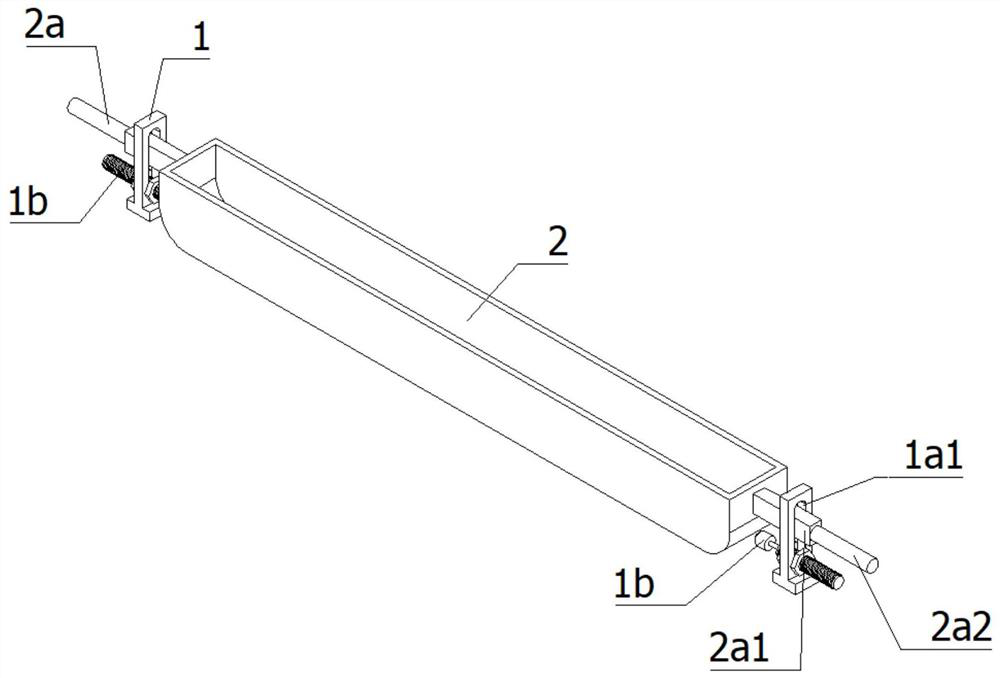

[0040] The frame 10 is U-shaped with an upward opening, and the transmission mechanism 3 includes two rotating shafts rotatably supported in the U-shaped frame 10 and located at both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com