Battery cell and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] 1. The preparation method of the cell

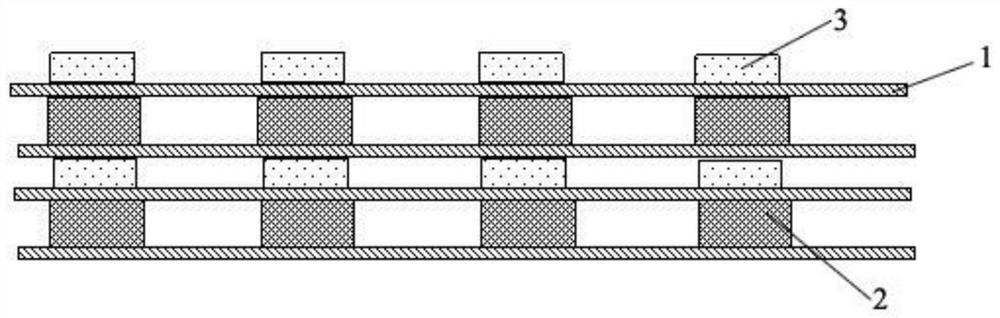

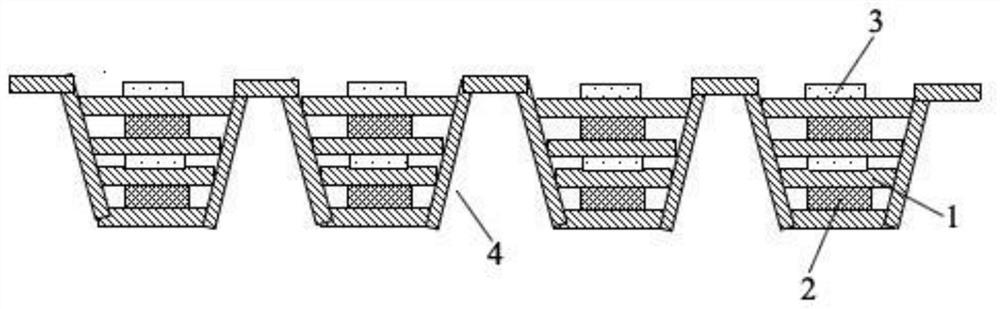

[0028] refer to Figure 1~3 , the first aspect of the present invention provides a method for preparing an electric core, comprising the following steps:

[0029] 1) The continuous first pole piece and the second pole piece are respectively divided into a first pole piece monomer 2 and a second pole piece monomer 3, wherein the polarity of the first pole piece and the second pole piece are opposite;

[0030] 2) Unwind a layer of diaphragm 1, place several first pole piece monomers 2 on the diaphragm 1, and press it tightly;

[0031] 3) Place a layer of diaphragm 1 on the first pole piece monomer 2, and place several second pole piece monomers 3 on the diaphragm 1, and the second pole piece monomer 3 is set corresponding to the first pole piece monomer 1 , compact;

[0032] 4) Repeat steps 2) to 3) until the required thickness / number of layers of the cell is reached, and heat press to form several continuous cell units;

[0033...

Embodiment 1

[0046] A method for preparing an electric core, comprising the steps of:

[0047] 1) Cut a number of first tabs on the edge of the continuous first pole piece, cut out a number of second tabs on the edge of the continuous second pole piece, and cut the continuous first pole piece and the second pole piece respectively Form the first pole piece monomer 2 and the second pole piece monomer 3, so that each first pole piece monomer 2 is formed with a first tab, and each second pole piece monomer 3 is formed with a second pole an ear, wherein the polarity of the first pole piece and the second pole piece are opposite;

[0048] 2) Unwind a layer of diaphragm 1, place several first pole piece monomers 2 on the diaphragm 1, set the first lugs of the first pole piece monomer 2 toward the same end, and press them tightly;

[0049] 3) Place a layer of diaphragm 1 on the first pole piece monomer 2, and place several second pole piece monomers 3 on the diaphragm 1, and the second pole piec...

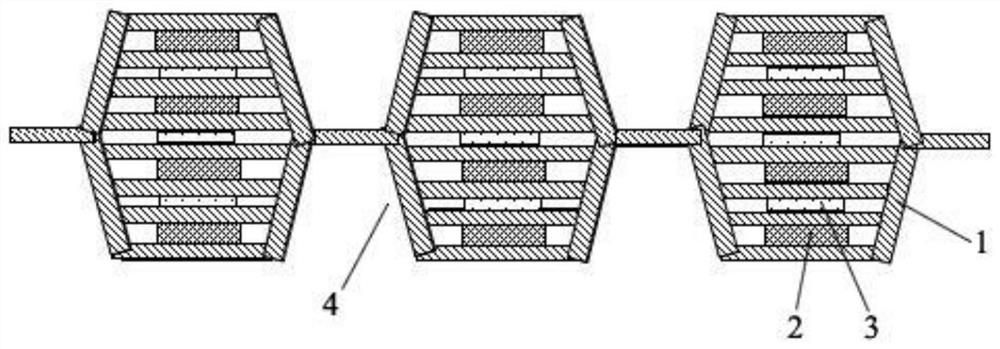

Embodiment 2

[0054] A method for preparing an electric core, comprising the steps of:

[0055] 1) Cut a number of first tabs on the edge of the continuous first pole piece, cut out a number of second tabs on the edge of the continuous second pole piece, and cut the continuous first pole piece and the second pole piece respectively Form the first pole piece monomer 2 and the second pole piece monomer 3, so that each first pole piece monomer 2 is formed with a first tab, and each second pole piece monomer 3 is formed with a second pole an ear, wherein the polarity of the first pole piece and the second pole piece are opposite;

[0056] 2) Unwind a layer of diaphragm 1, place several first pole piece monomers 2 on the diaphragm 1, set the first lugs of the first pole piece monomers 2 toward the same end, and press them tightly;

[0057] 3) Place another layer of diaphragm 1 on the first pole piece monomer 2, and place several second pole piece monomers 3 on the diaphragm 1, and the second po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com