Three-color mold structure

A formwork and upper base technology, applied in the field of three-color mold structure, can solve the problems of many production processes, low automation level, troublesome assembly, etc., and achieve the effect of simple and compact overall structure, high automation level, small and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

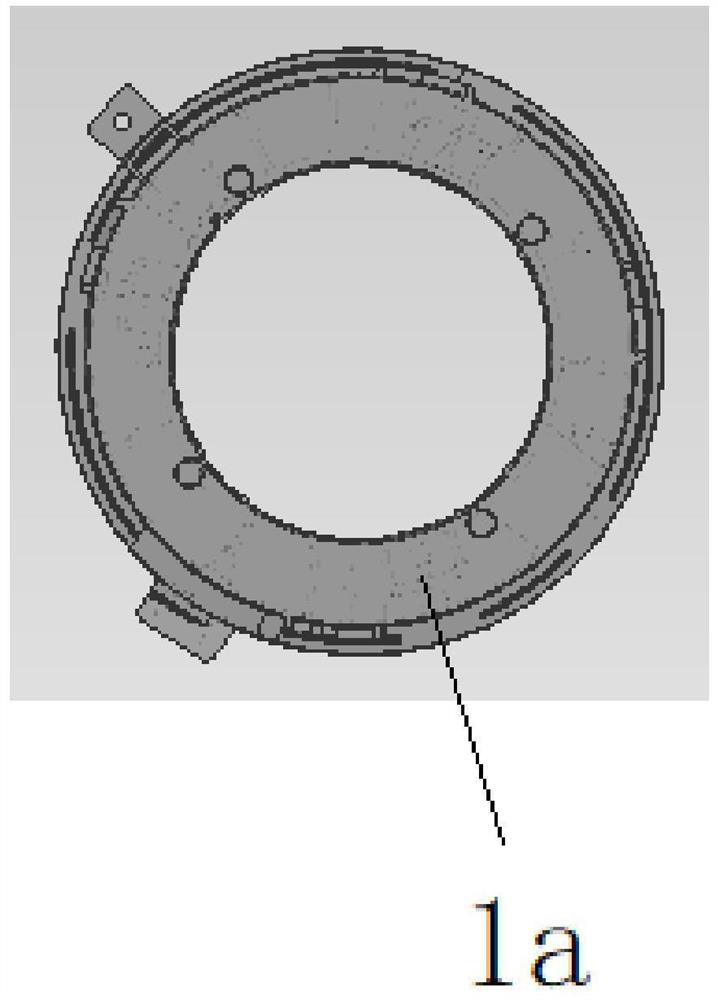

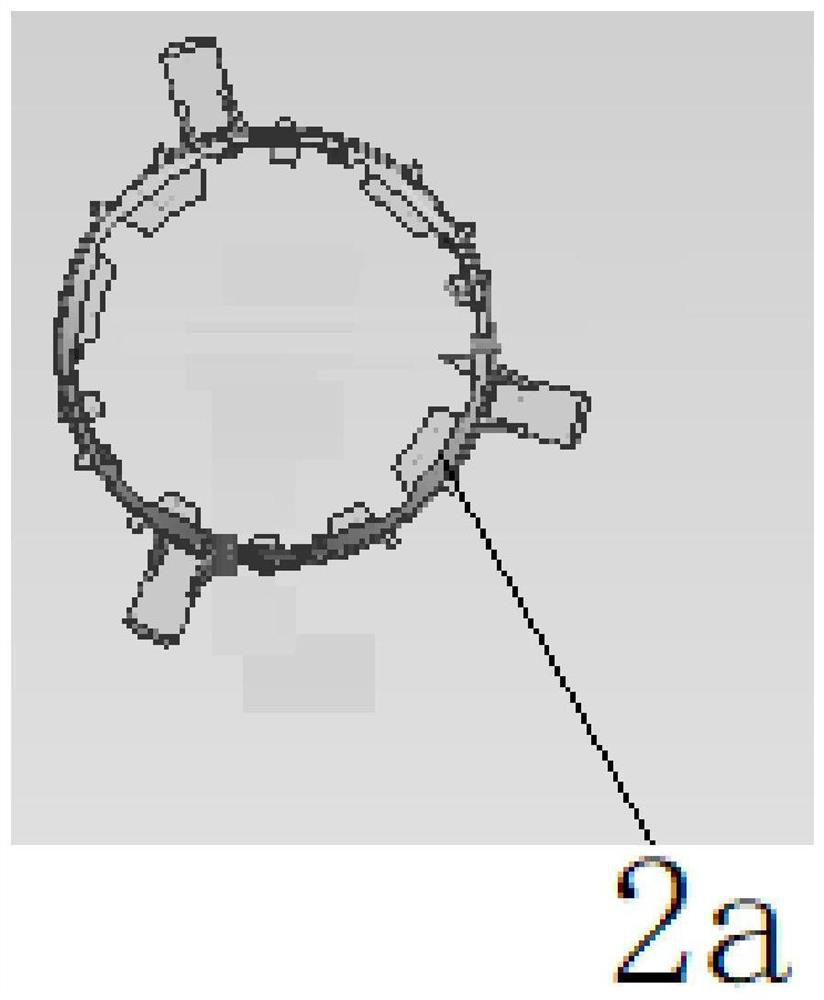

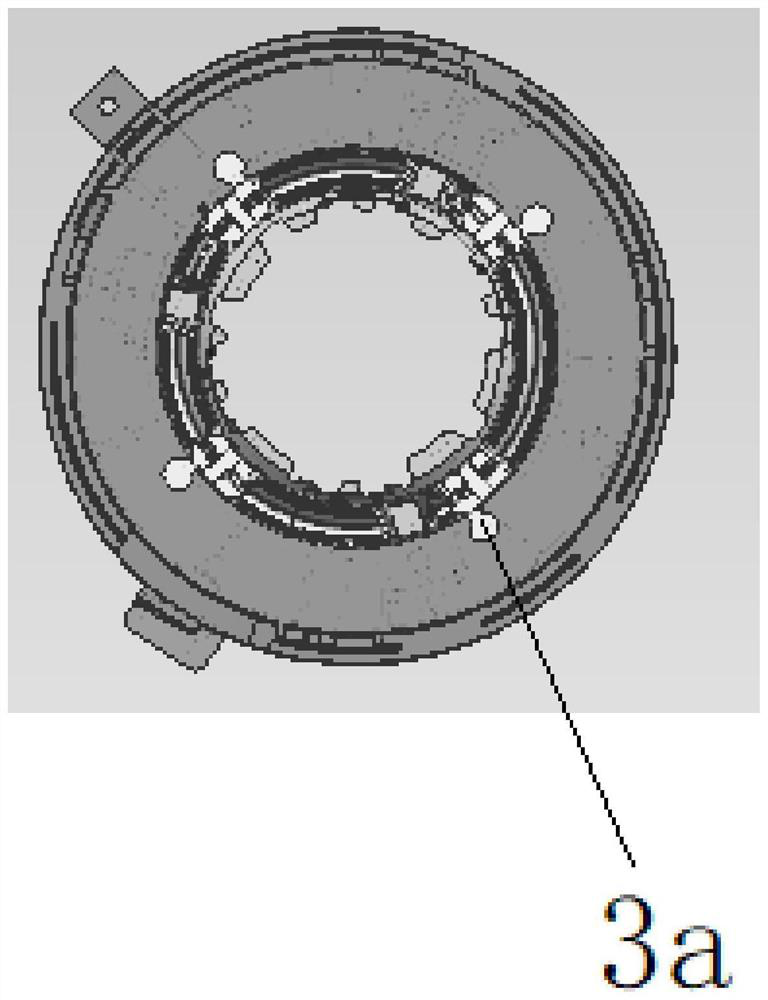

[0028]A three-color mold structure, including a mold base 1. The mold base 1 includes an upper seat body 2 and a lower seat body 3 that are spaced up and down and connected to each other, and the upper seat body 2 is horizontally arranged side by side for simultaneous injection molding. The station 4 and the second station 5, and the third station 6 for separate injection molding. The first station 4 and the second station 5 can be injection molded at the same time using existing technology, and the first station 4 is fixed on the upper base. On the body 2, the second station 5 and the third station 6 are fixed on a lifting rotating body that can be raised and lowered up and down and rotated, and also includes a mold base 1 for injection molding on the transfer station The manipulator of the product, the manipulator can use the existing technology, which is not shown in the figure. The lifting rotating body includes a square turntable 7 embedded on the upper base body 2 and a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com