Manufacturing process of simple and retro tie-dyed retro knitted vamp

A production process and technology for knitted fabrics, which are applied in dyeing method, textile and papermaking, enzyme/microorganism biochemical treatment, etc., can solve the problems of insufficient tie-dyeing effect, insufficient color layering, unnatural color transition, etc. The effect of clear color gradation, improved color fastness and natural color transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

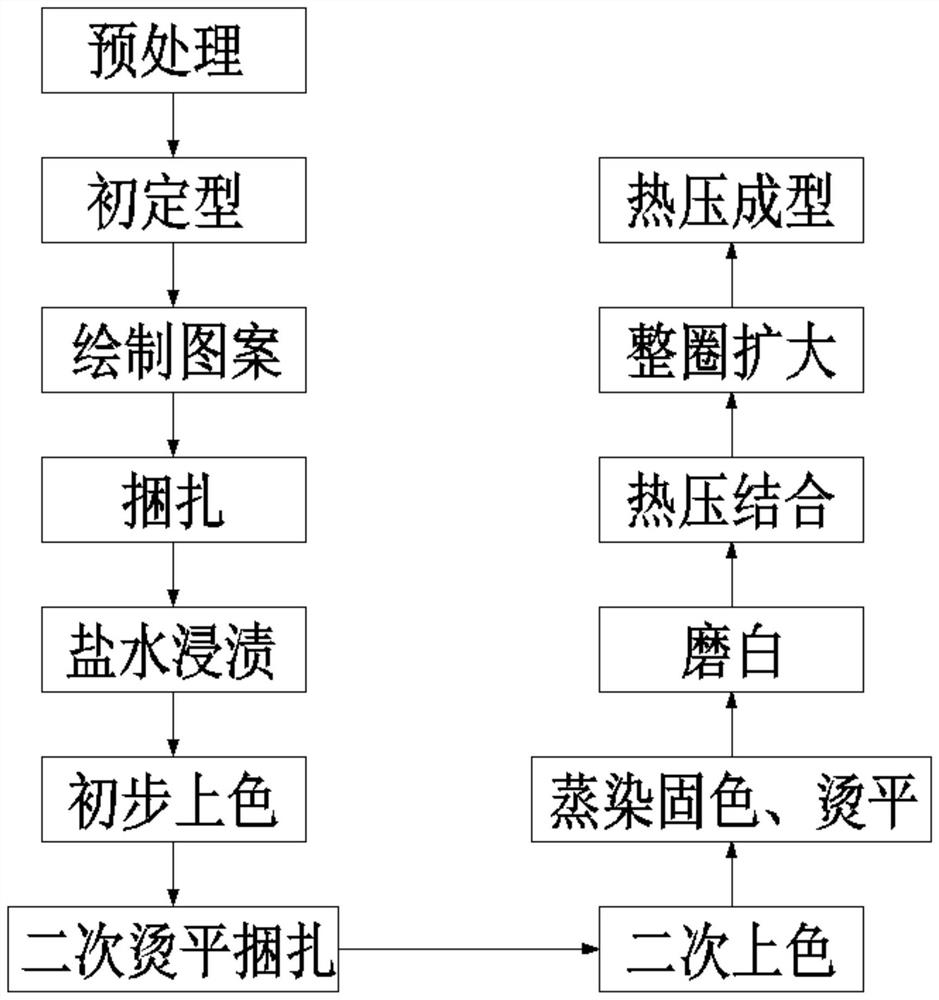

Method used

Image

Examples

Embodiment 1

[0033] A manufacturing process of simple and nostalgic tie-dye retro knitted vamp, comprising the following steps:

[0034] S1. Pretreatment: put the woven fabric into the boiled lye and continue to stir for 22 minutes, then take out the clean water and rinse it, then soak it in the biological enzyme solution for 45 minutes, then take it out and wash it, repeat this step twice;

[0035] S2. Preliminary setting: the pretreated fabric is manually steamed with an iron, and the preliminary setting is ironed;

[0036] S3. Drawing patterns: draw the required patterns on the fabric according to the design requirements;

[0037] S4. Binding: according to the pattern requirements, the binding is looser where more translucent is required, and tighter where less translucent is required;

[0038] S5, salt water immersion: immerse the bundled knitted fabric in 20% salt water for 10 minutes, remove it, drain and dry;

[0039] S6. Preliminary coloring: color the de-dried knitted fabric, pr...

Embodiment 2

[0053] A manufacturing process of simple and nostalgic tie-dye retro knitted vamp, comprising the following steps:

[0054] S1. Pretreatment: put the woven fabric into the boiled lye and continue to stir for 25 minutes, then take out the clean water and rinse it, then soak it in the biological enzyme solution for 50 minutes, then take it out and wash it, repeat this step twice;

[0055] S2. Preliminary setting: the pretreated fabric is manually steamed with an iron, and the preliminary setting is ironed;

[0056] S3. Drawing patterns: draw the required patterns on the fabric according to the design requirements;

[0057] S4. Binding: according to the pattern requirements, the binding is looser where more translucent is required, and tighter where less translucent is required;

[0058] S5. Soaking in salt water: immerse the bundled knitted fabric in 25% salt water for 13 minutes, remove it, drain and dry;

[0059] S6. Preliminary coloring: color the de-dried knitted fabric, p...

Embodiment 3

[0073] A manufacturing process of simple and nostalgic tie-dye retro knitted vamp, comprising the following steps:

[0074] S1. Pretreatment: put the woven fabric into the boiled lye and continue to stir for 28 minutes, then take out the clean water and rinse it, put it in the biological enzyme solution and soak it for 55 minutes, then take it out and wash it, repeat this step 3 times;

[0075] S2. Preliminary setting: the pretreated fabric is manually steamed with an iron, and the preliminary setting is ironed;

[0076] S3. Drawing patterns: draw the required patterns on the fabric according to the design requirements;

[0077] S4. Binding: according to the pattern requirements, the binding is looser where more translucent is required, and tighter where less translucent is required;

[0078] S5, salt water immersion: immerse the bundled knitted fabric in 30% salt water for 15 minutes, remove it, drain and dry;

[0079] S6. Preliminary coloring: color the de-dried knitted fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com