Automobile windshield production transfer device

A windshield and transfer device technology, which is applied in the field of plastic production, can solve problems such as inconvenient access, low transfer efficiency, and poor stability, and achieve the effects of convenient access and transfer, high transfer efficiency, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention are described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention:

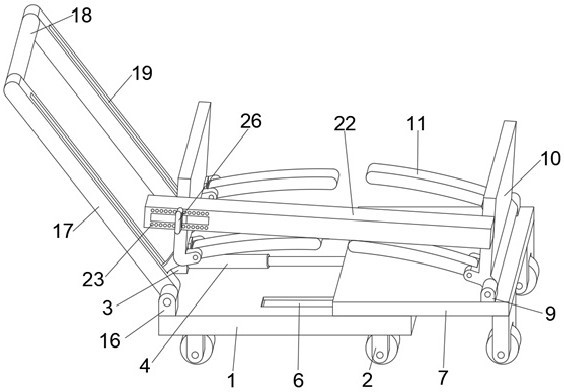

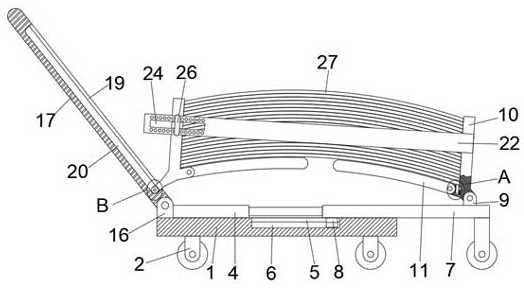

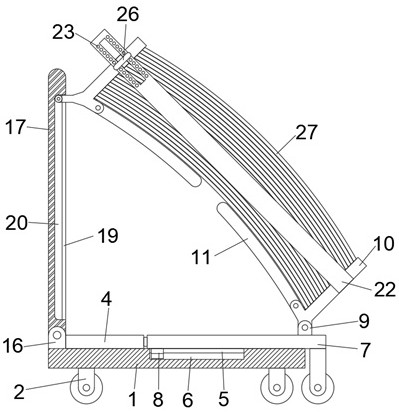

[0032] Such as Figure 1-7 Shown: a transfer device for automobile windshield production, including a base plate 1, the four corners of the bottom surface of the base plate 1 are fixedly connected with rollers 2, the upper surface of the base plate 1 is fixedly connected with a fixed seat 3, and the fixed seat 3 is fixedly connected with a hydraulic lift Rod 4, the bottom plate 1 is provided with the first bar-shaped groove 5 arranged left and right symmetrically, the first chute 6 is opened in the bottom plate 1 below the first bar-shaped groove 5, and the bottom plate 1 is provided with an extension plate 7, hydraulic lift The other end of the shrink rod 4 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com