Round wood edge scraping machine for workshop

A log and edge machine technology, used in forming/shaping machines, wood processing appliances, special forming/shaping machines, etc., can solve the problems of easy cutting operators, low production efficiency, manual fatigue, etc., to avoid The effect of machine scratches, reducing defective products and reducing accidental injury rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

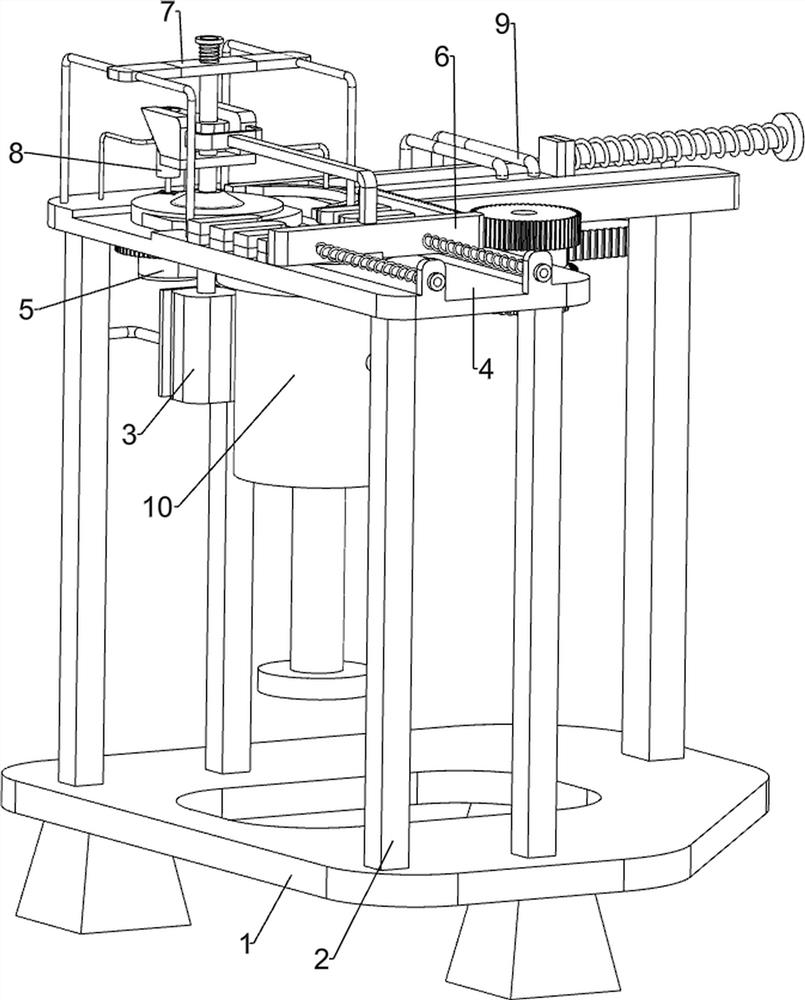

[0081] A log scraper for workshops, such as figure 1 As shown, it includes a base 1, a frame 2, a motor 3, a workbench 4, a transmission device 5, a feeding device 6, a pressing device 7, an edge scraping device 8 and a reclaiming device 9. There are five machines on the top of the base 1. Frame 2, a workbench 4 is arranged on the top of the frame 2, a motor 3 is arranged on the upper part of the two racks 2 on the right side of the front side, a transmission device 5 is arranged on the bottom of the right side of the workbench 4 and the output shaft of the motor 3, and the workbench 4 The right side is equipped with a feeding device 6, which is connected with the transmission device 5, and the front right part of the top of the workbench 4 is provided with a pressing device 7, and the pressing device 7 is provided with a scraping device 8, and the top of the workbench 4 is left A reclaimer 9 is provided on the side.

[0082] People can use the present invention to scrape rou...

Embodiment 2

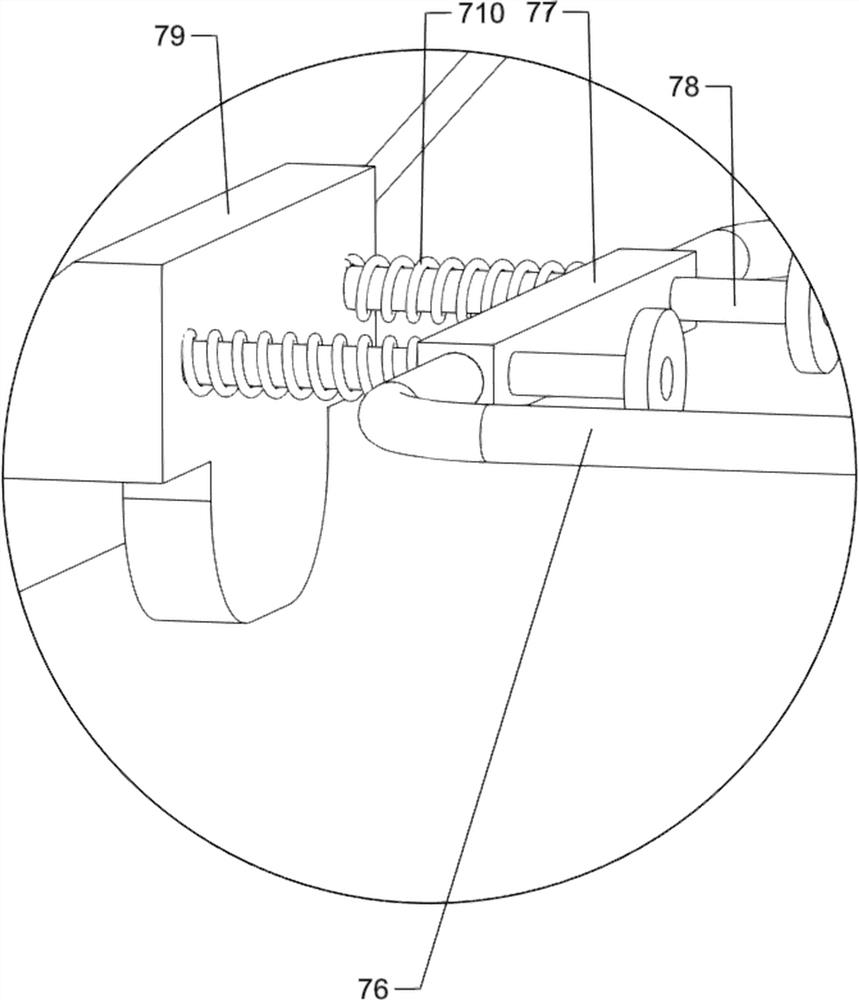

[0084] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the transmission device 5 includes a first rotating shaft 51, a first gear 52, a rotating disk 53, a second rotating shaft 54, a second gear 55, a first belt 56 and a third rotating shaft 57, and the output shaft of the motor 3 is provided with a first A rotating shaft 51, the first rotating shaft 51 is provided with a first gear 52, the top of the first rotating shaft 51 is provided with a rotating disk 53, the rotating disk 53 is located on the right side of the top of the workbench 4, and the right side of the workbench 4 is rotatably provided with a second rotating shaft 54, The second rotating shaft 54 is provided with a second gear 55, the first gear 52 meshes with the second gear 55, and the left side rotation of the workbench 4 is provided with a third rotating shaft 57, which is connected between the third rotating shaft 57 and the second rotating shaft ...

Embodiment 3

[0095] On the basis of Example 2, such as Figure 7 As shown, it also includes a feeding device 10, and the feeding device 10 includes a fourth connecting frame rod 101, a mounting ring 102, an outer frame 103, a third pull rod 104 and a fifth spring 105, and the middle part on the right side of the bottom of the workbench 4 is provided. There are two fourth connecting rods 101, an outer frame 103 is arranged between the two fourth connecting rods 101, and a third pull rod 104 is slidingly provided inside the outer frame 103, and the third pull rod 104 is connected to the inner bottom of the outer frame 103. The fifth spring 105 is connected between them, and the fifth spring 105 is sleeved on the upper part of the third pull rod 104, and the middle part of the right side of the bottom of the workbench 4 is provided with a mounting ring 102.

[0096] The feeding device 10 is transported to install the round planks, and can transfer the round planks to the feeding device 6, wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com