Compact high-precision constant-force actuator and application method

A high-precision, compact technology, applied in the direction of instruments, measuring inclination, force/torque/power measuring instruments, etc., can solve the problems of loss of compact structure and partial control quality, low precision of force control, poor effect, etc. Achieve the effect of beautiful and compact internal structure, reduce tracheal connection, and improve sensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

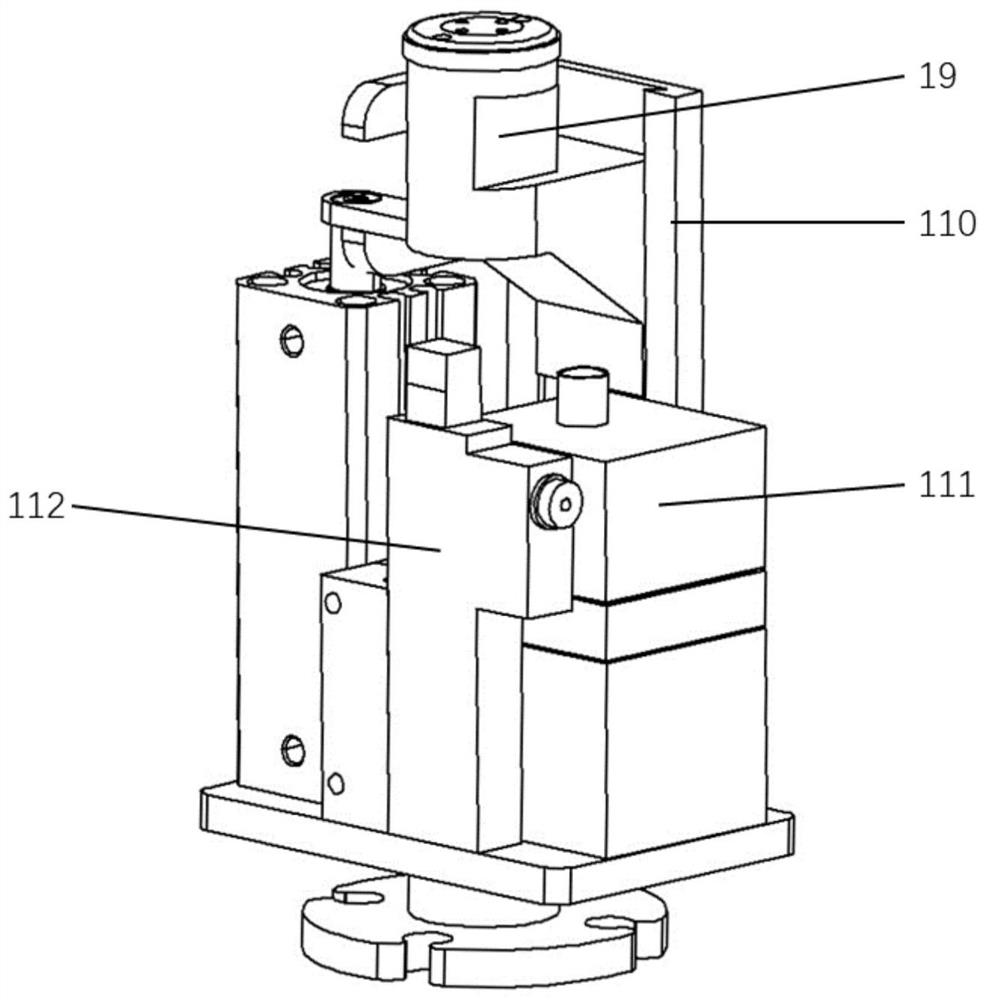

[0047] see Figure 1-3 , a compact high-precision constant force actuator, including a cylinder 13, a force sensor 11, a fixed flange 5, a sliding table 19 and a guide rail 110. Cylinder 13 is a low-friction cylinder.

[0048] combined with figure 1 , the constant force actuator is installed at the end of the industrial robot through the fixed flange 5, and the clean air compressed by the air compressor provides the air source for the cylinder through the air supply port 2. There are three connection ports on the surface of the shell 6, the pneumatic components inside the device exhaust the air through the exhaust port 3, and the cable connector 4 is responsible for the power supply of the internal components and the signal transmission of the sensor. The telescopic executive part 1 can be connected with the processing tool through threads, and a circle of telescopic dustproof cover 7 is arranged on its periphery.

[0049] combined with figure 2 And attached image 3 , t...

Embodiment 2

[0054] The invention also discloses an application method of the device, which includes: before starting the operation, connecting the end of the telescopic actuator 1 with the processing tool, keeping the constant force actuator vertical, and the force sensor 12 reflecting the gravity of the processing tool. During the grinding process, the inclination sensor 17 will reflect the posture information of the device, and obtain the component G of the gravity of the processing tool in this posture, and the actual size of the contact force Fa is the value Fp displayed by the force sensor 12 and the component of the gravity of the processing tool G difference. During the grinding process, the contact force Fa is constantly changing. The host computer compares the contact force Fa with the set force Fd, and calculates the difference ΔFd between the two. After dividing ΔFd by the cross-sectional area of the cylinder cavity, the pressure to be adjusted ΔPd is obtained. ΔPd plus the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com