Centrifugal separation and extraction equipment for tea stoste

A technology of centrifugal separation and extraction equipment, applied in separation methods, solvent extraction, solid solvent extraction and other directions, can solve problems such as unfavorable continuous and synchronous centrifugal separation of tea stock liquid, improve the efficiency of pulverization and centrifugal separation, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

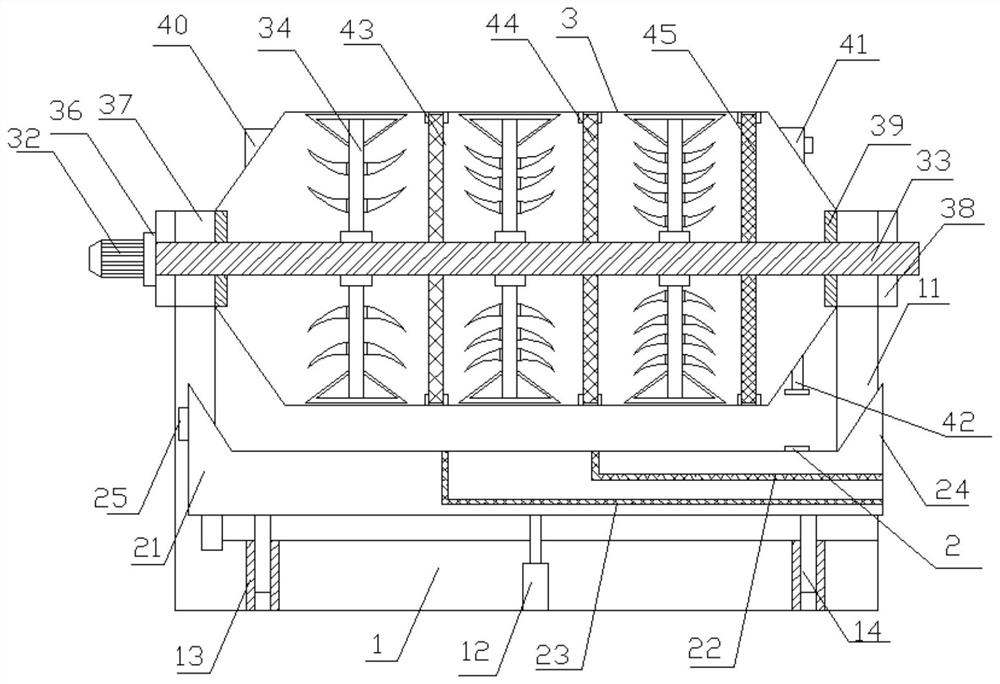

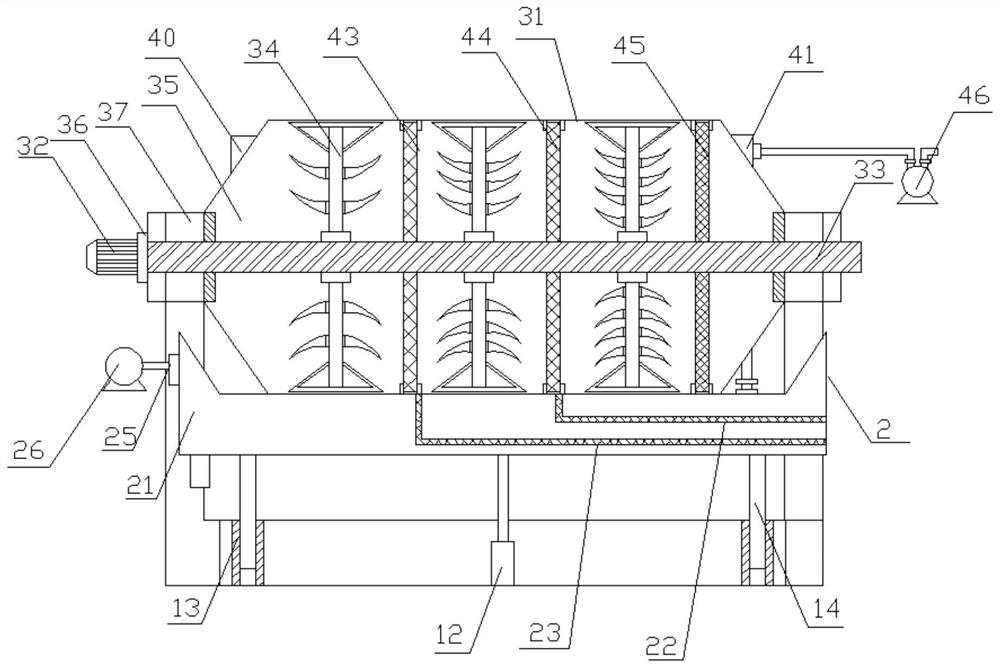

[0025] like Figure 1-4 As shown, a kind of centrifugal separation and extraction equipment for tea stock liquid in this embodiment includes a base 1, a lifting extraction box 2, and a centrifugal separation tank 3. The lifting extraction box 2 is arranged above the base 1 and can be vertically aligned with the base 1. Move, the centrifuge tank 3 is located above the lifting extraction box 2;

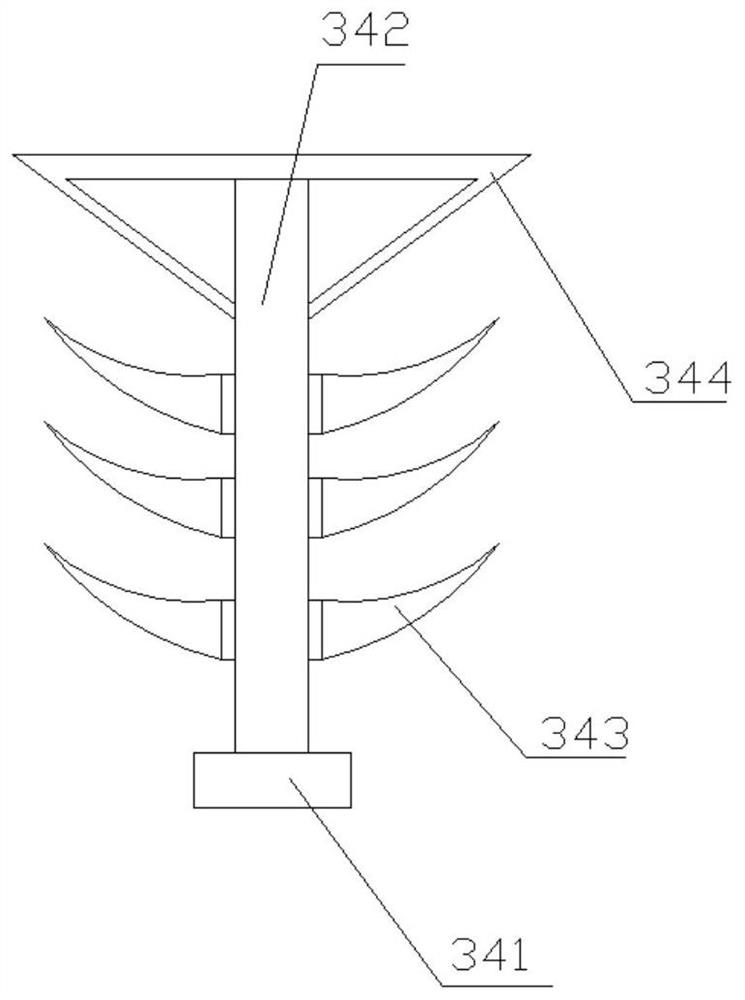

[0026] The centrifuge tank 3 includes a tank body 31, a drive motor 32, a stirring shaft 33, and a plurality of stirring and crushing mechanisms 34 for stirring the tea stock solution and carrying out multistage crushing of the tea leaves. One side runs through its inner cavity 35 to the other side, the drive motor 32 is connected to the end of the stirring shaft 33 through a coupling 36, and a plurality of stirring and pulverizing mechanisms 34 are distributed in the radial direction from one end to the other end of the stirring shaft 33;

[0027] The lifting extraction box 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com