Preparation method of brown high-protein yoghourt and prepared yoghourt

A brown and yoghurt technology, applied in milk preparations, dairy products, other dairy products, etc., can solve the problems of protein aggregation and poor flavor of brown yogurt, and achieve protein content improvement, uniform color, smooth and delicious, and appropriate viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

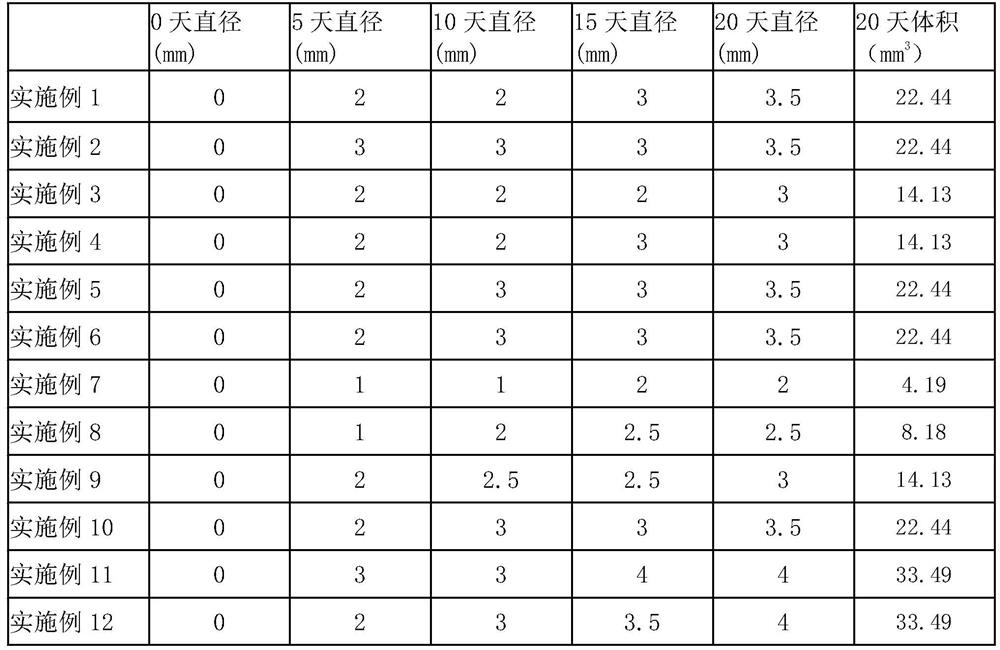

Examples

Embodiment 1

[0051] Raw materials are obtained according to the following proportions by weight: 950 g of raw milk, 50 g of glucose fermentation, 0.5 g of active lactic acid bacteria Lactobacillus bulgaricus and 0.5 g of Streptococcus thermophilus. The process steps are as follows:

[0052] A Raw milk pretreatment, centrifuging raw cow milk to remove impurities contained in raw cow milk;

[0053] B batching, add glucose to the raw milk obtained in step A, and stir in a vacuum mixer for 15 minutes;

[0054] C is homogenized and sterilized, and the material obtained in step B is homogenized and sterilized;

[0055] Homogenization pressure 150bar, homogenization temperature 62°C;

[0056] The sterilization conditions are: temperature 95°C, time 300s.

[0057] D browning treatment, browning the material obtained in step C;

[0058] Browning condition temperature is 92°C, 2h.

[0059] E inoculated and fermented, the temperature of the material obtained in step D was lowered to 40° C., inoc...

Embodiment 2

[0063] The raw materials are obtained according to the following proportions by weight: 950 g of raw milk, 50 g of fructose, 0.4 g of active lactic acid bacteria Lactobacillus bulgaricus and 0.4 g of Streptococcus thermophilus. The process steps are as follows:

[0064] A Raw milk pretreatment, centrifuging raw cow milk to remove impurities contained in raw cow milk;

[0065] For B batching, add fructose to the raw milk obtained in step A, and stir in a vacuum mixer for 20 minutes;

[0066] C is homogenized and sterilized, and the material obtained in step B is homogenized and sterilized;

[0067] Homogenization pressure 150bar, homogenization temperature 65°C;

[0068] The sterilization conditions are: temperature 95°C, time 300s.

[0069] D browning treatment, browning the material obtained in step C;

[0070] Browning condition temperature is 85°C, 3h.

[0071] E inoculated and fermented, the temperature of the material obtained in step D was lowered to 35° C., inocula...

Embodiment 3

[0075] The raw materials are obtained according to the following proportions by weight: 920 g of raw milk, 80 g of maltose, 0.4 g of active lactic acid bacteria Lactobacillus bulgaricus and 0.4 g of Streptococcus thermophilus. The process steps are as follows:

[0076] A Raw milk pretreatment, centrifuging raw cow milk to remove impurities contained in raw cow milk;

[0077] For B batching, add maltose to the raw milk obtained in step A, and stir in a vacuum mixer for 20 minutes;

[0078] C is homogenized and sterilized, and the material obtained in step B is homogenized and sterilized;

[0079] Homogenization pressure 150bar, homogenization temperature 65°C;

[0080] The sterilization conditions are: temperature 95°C, time 300s.

[0081] D browning treatment, browning the material obtained in step C;

[0082] Browning condition temperature is 88°C, 2h.

[0083] E inoculated and fermented, the temperature of the material obtained in step D was lowered to 38° C., inoculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com