Drip irrigation belt laying machine

A drip irrigation tape laying machine and drip irrigation tape technology are applied in the fields of botany equipment and methods, climate change adaptation, gardening, etc., which can solve the problems of high labor intensity, low operation efficiency, affecting normal laying, etc., so as to reduce labor intensity and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

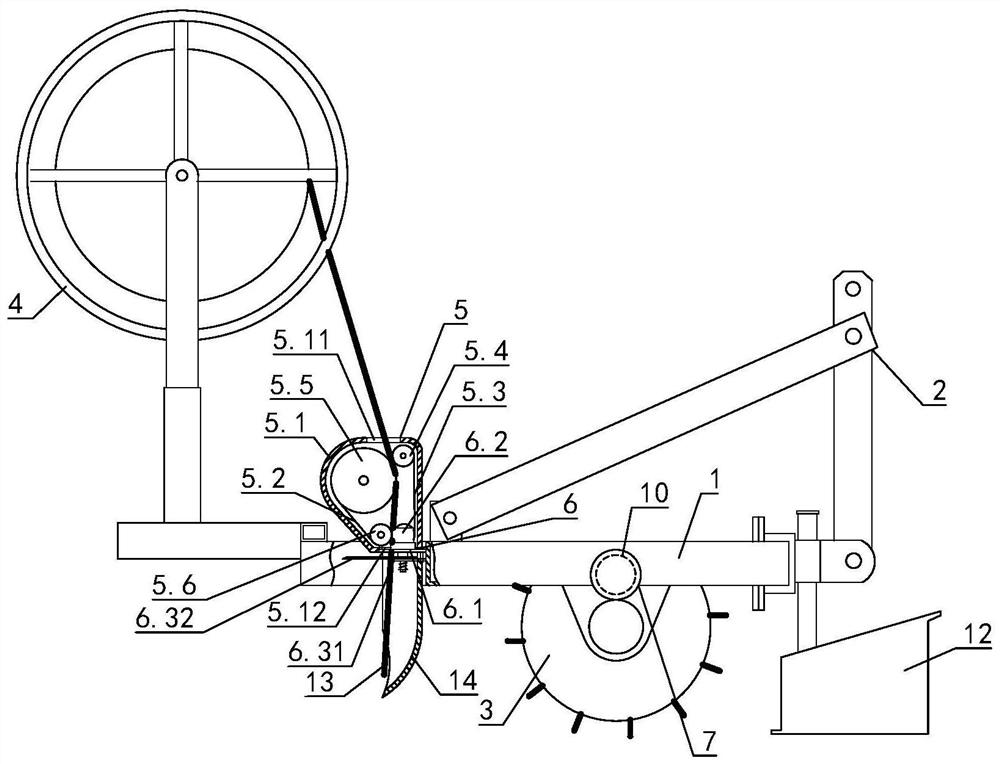

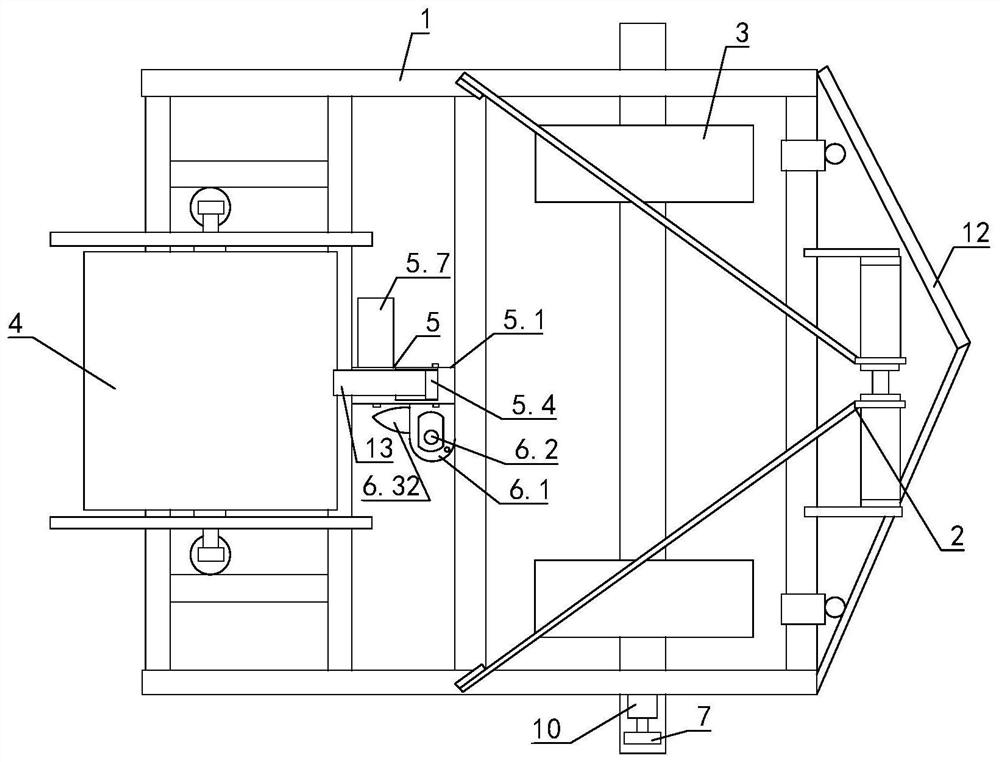

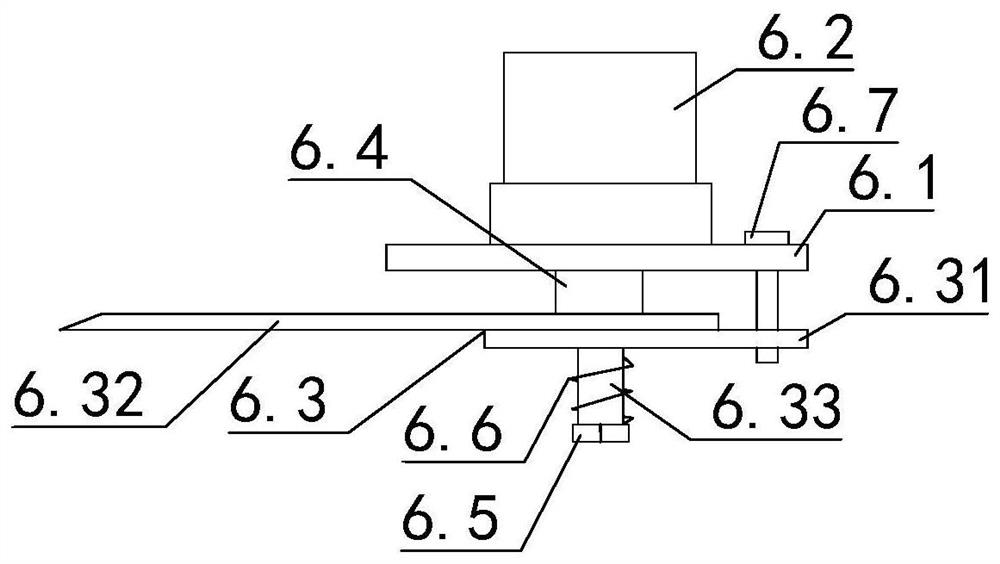

[0021] Such as Figure 1 to Figure 7 Shown, a kind of drip irrigation belt laying machine, it comprises frame 1; Connection; the frame 1 is rotated with a drip irrigation belt roller 4, and the drip irrigation belt roller 4 is wound with a drip irrigation belt 13 for laying; the frame 1 is fixed with a drip irrigation belt transmission mechanism 5 placed below the drip irrigation belt roller 4, and the drip irrigation The belt transmission mechanism 5 includes a housing 5.1, a driving belt 5.2 and a driven belt 5.3; the housing 5.1 is fixedly connected to the frame 1, the top of the housing 5.1 is provided with a belt inlet 5.11, and the bottom of the housing 5.1 is provided with a belt outlet Port 5.12; the housing 5.1 is provided with a driving belt 5.2 and the driven belt 5.3 facing downwards in the conveying direction, and the housing 5.1 is provided with two supporting rollers 5.4 arranged up and down for rotation, between the two supporting rollers 5.4 The transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com