A new energy vehicle charging gun

A new energy vehicle, charging gun technology, applied in electric vehicle charging technology, charging stations, electric vehicles and other directions, can solve the problems of charging interruption, insufficient connection, charging gun detachment, etc., to achieve the effect of improving the fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

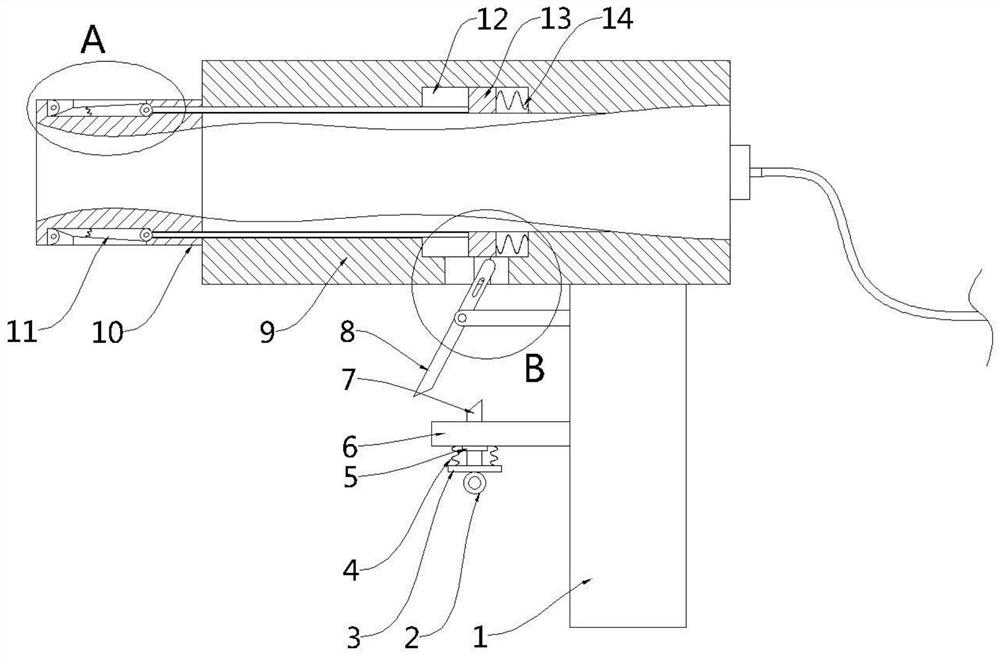

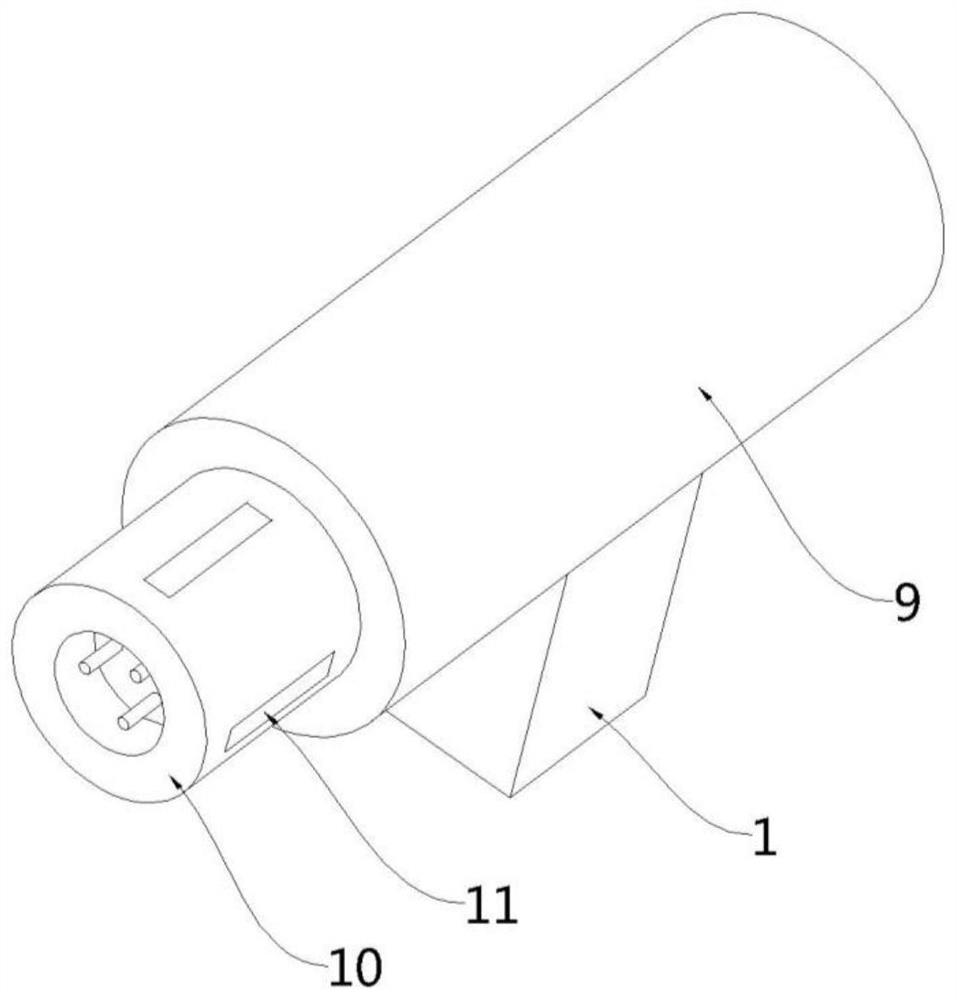

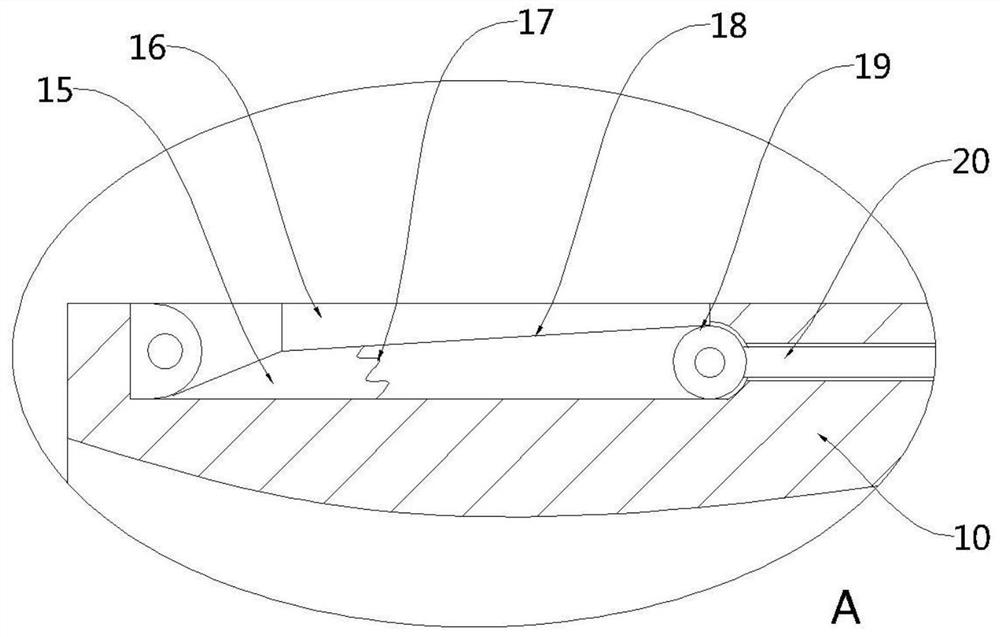

[0025] see Figure 1-4 , this embodiment provides a new energy vehicle charging gun, including a gun body 9, a handle 1 is fixedly arranged on one side of the bottom of the gun body 9, a charging head 10 is provided at one end of the gun body 9, and the outer wall of the charging head 10 is movable Several clamping parts 11 distributed in the circumferential direction are installed, and the side of the handle 1 facing the charging head 10 is provided with a device for driving the clamping parts 11 to protrude from the charging head 10 to abut against the charging hole of the car The driving part of the inner wall; specifically, the clamping part 11 includes a clamping plate 16 rotatably mounted on the outer wall of the charging head 10, and the clamping plate 16 has a first slope 18 on the side facing the charging head 10; the driving The part includes a fixed rod 22 fixedly installed on the side of the handle 1 facing the charging head 10 and a rotating rod 8 arranged at the ...

Embodiment 2

[0032] see figure 1 , a charging gun for new energy vehicles. Compared with Embodiment 1, the end of the handle 1 facing the charging head 10 in this embodiment is also provided with a limit assembly for preventing the reverse rotation of the rotating rod 8. Through the setting of the limit assembly, when the rotating rod 8 drives the clamping plate 16 to rotate outward and abut against the inner wall of the charging hole of the car, the position of the rotating rod 8 can be limited to prevent the rotating rod 8 from being under the action of the third elastic body 17 The rotating rod 8 is forced to rotate in the opposite direction, thereby causing the clamping plate 16 to be automatically retracted, so that the cooperation effect between the charging head 10 and the charging hole of the car is reduced.

[0033] Specifically, the limiting assembly includes a fixed plate 6 fixedly arranged on the side wall of the handle 1 and a movable stop rod 7 vertically penetrating through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com