Test data three-dimensional display method based on data fusion

A technology of test data and three-dimensional display, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of feedback data information acquisition and comprehensive research and judgment lag, unable to load parts, and insufficient information acquisition efficiency, so as to improve the three-dimensional display and Playback capability, improving analysis efficiency, and accelerating test debugging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

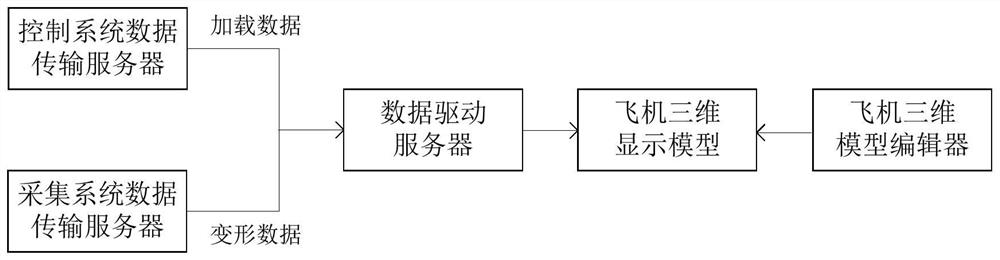

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] An embodiment of the present invention provides a method for three-dimensional display of experimental data based on data fusion, the method comprising:

[0033] S1, obtaining test data; the test data includes: test loading data and testing machine deformation data;

[0034] S2, establishing a three-dimensional model of the testing machine;

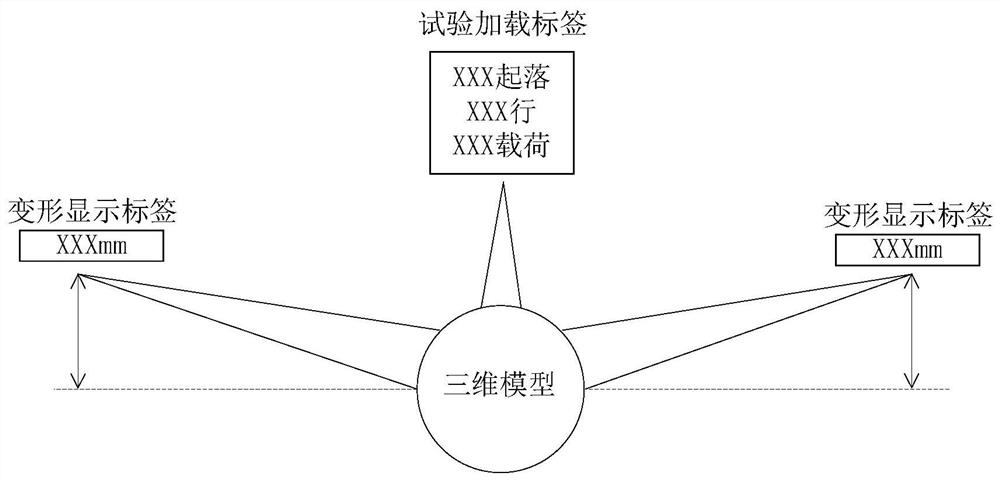

[0035] S3, displaying the test data in real time at the corresponding position of the test three-dimensional model.

[0036] In S1, the test loading data includes: load information applied to different positions of the testing machine during the test;

[0037] The test deformation data includes: during the test process, under the conditions of the test loading data, deformation information of different positions of the testing machine.

[0038] In S2, the test three-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com