A kind of biomass organic fertilizer processing system

An organic fertilizer and processing system technology, applied in the direction of drying solid materials, dryers, heating devices, etc., can solve the problems of insufficient drying time, condensation, and low drying degree of bio-organic fertilizers, so as to improve the subsequent utilization rate and increase Improvement of processing productivity and drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

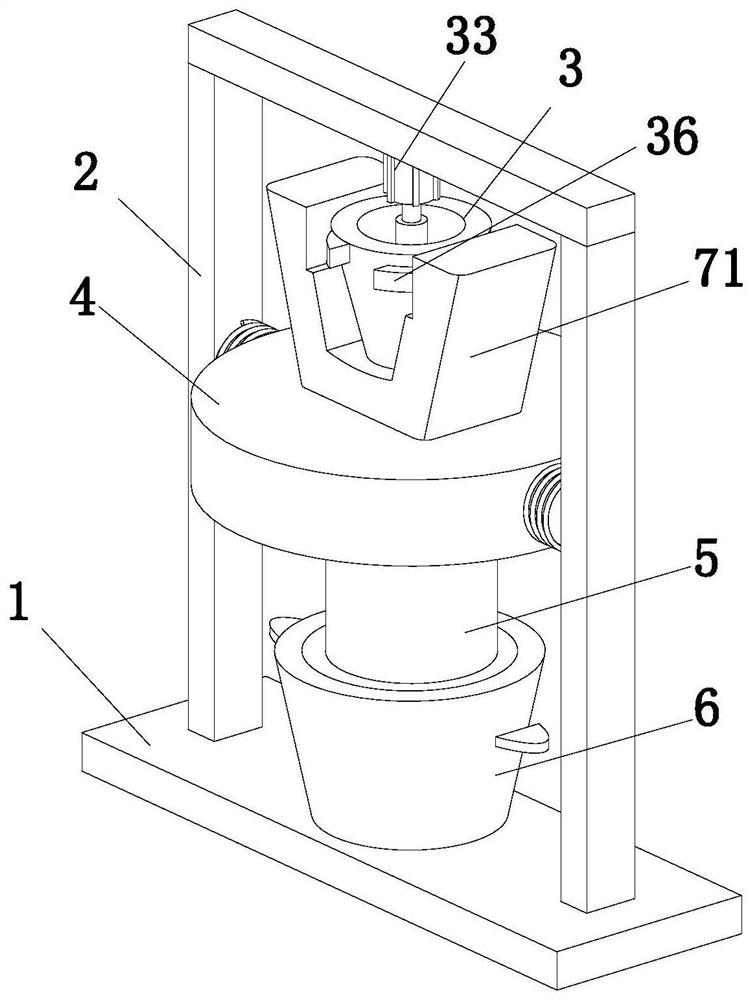

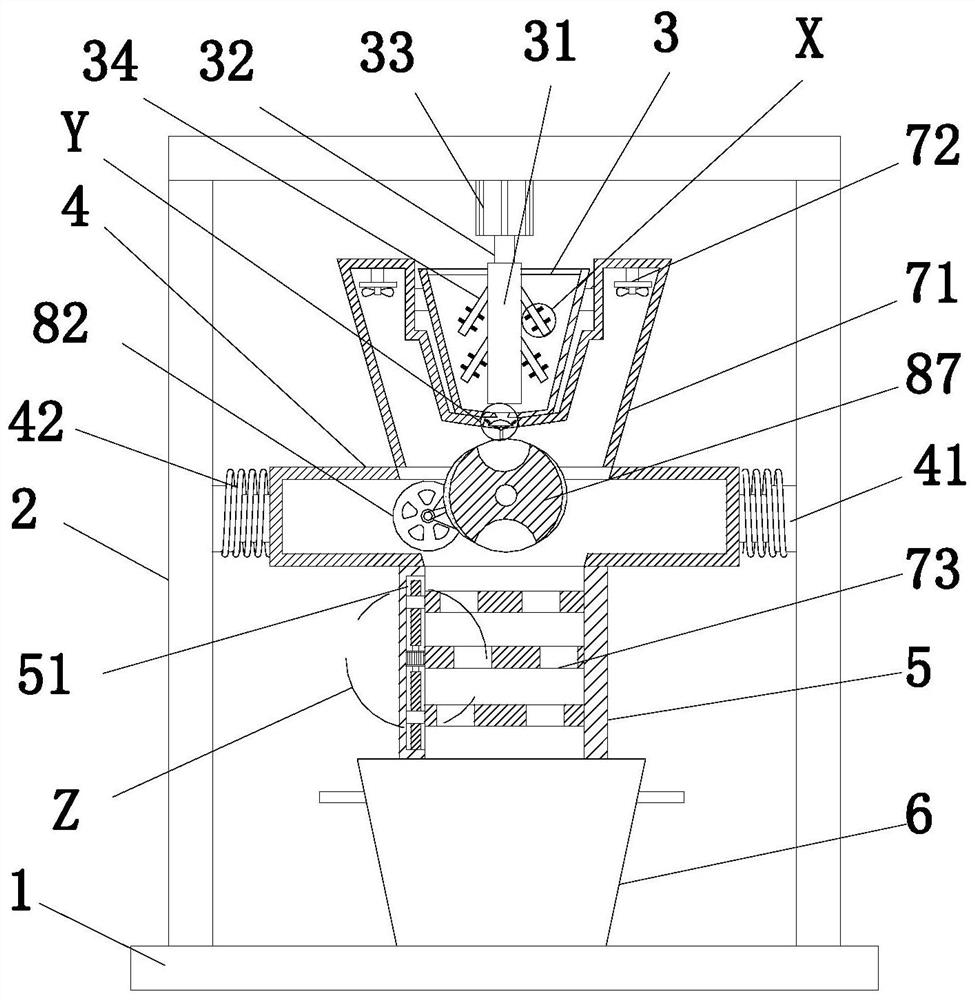

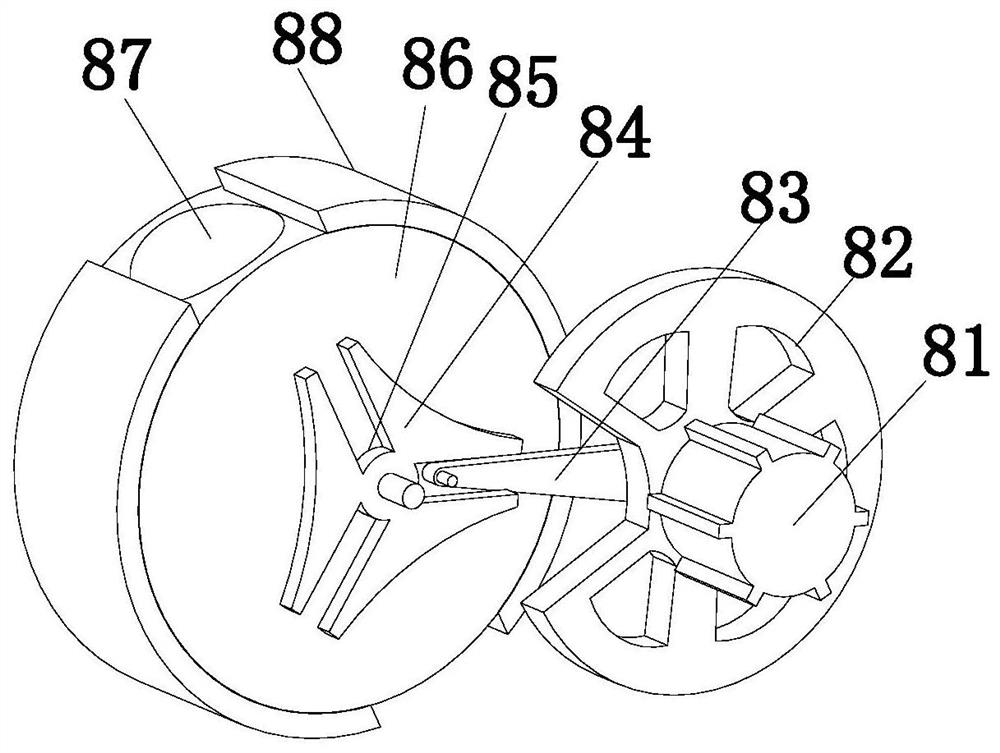

[0028] Such as Figure 1 to Figure 6 As shown, it includes base 1, 匚-shaped frame 2, storage tank 3, round table 4, feeding pipe 5, collecting tank 6, air-drying device 7 and feeding device 8, and the upper end surface of the base 1 is equipped with an opening to The lower 匚-shaped frame 2, the middle part of the 匚-shaped frame 2 is sequentially provided with a material tank 3, a round table 4, a feeding tube 5 and a material collection tank 6 from top to bottom, and the outside of the material tank 3 is provided with an air-drying device 7, And the bottom of the storage tank 3 and the air-drying device 7 all communicate with the inside of the round table 4, the bottom of the round table 4 is fixedly connected with the upper end of the feeding pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com