Pressure relief valve easy to install

A technology of easy installation and pressure relief valve, applied in the field of pressure relief valve, can solve the problems of inconvenient installation, cumbersome disassembly and assembly steps, and affecting installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

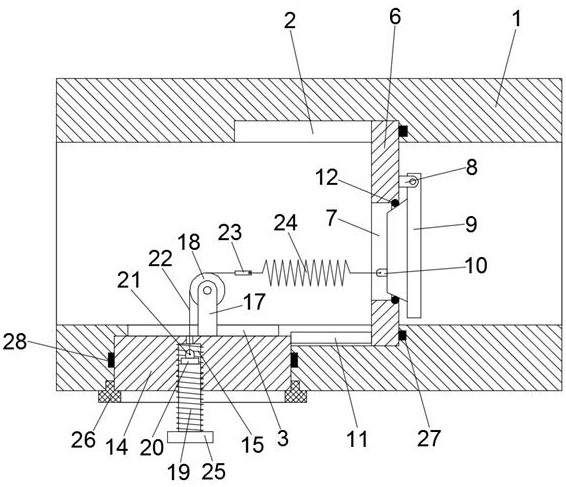

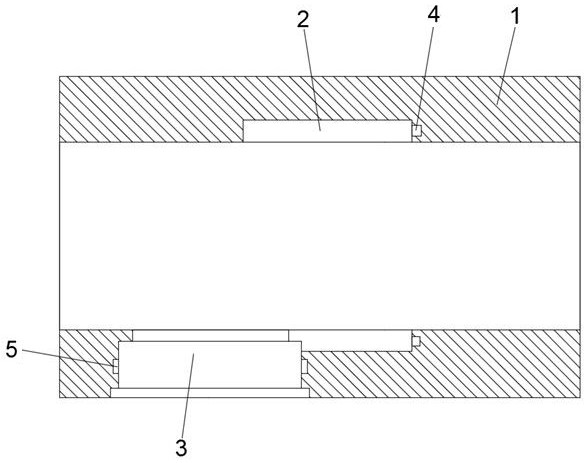

[0029] see Figure 1-2 , a pressure relief valve that is easy to install, including a valve body 1, a partition 6 and a mounting block 14, the inner wall of the valve body 1 is provided with a chute 2, and the partition 6 is slidably clamped in the chute 2, so A stepped mounting hole 3 for accommodating the mounting block 14 is provided on the outer wall of one side of the valve body 1;

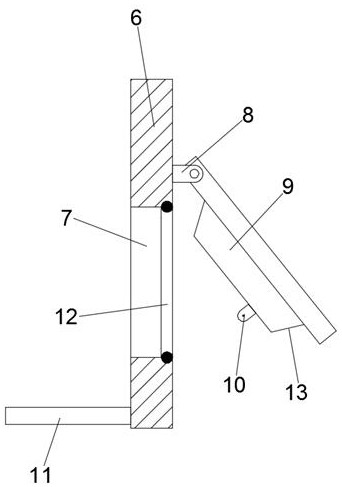

[0030] see image 3 , the partition 6 is provided with a pressure relief port 7, and the end surface of the partition 6 away from the installation hole 3 is provided with a hinged seat 8, and the hinged seat 8 is rotatably connected with a seal for blocking the pressure relief port 7. A cover 9, a first connection seat 10 is installed on the end surface of the cover 9 facing the pressure relief port 7;

[0031] see Figure 4-5 , the mounting block 14 is provided with a threaded hole 15, the bottom of the threaded hole 15 is provided with a through hole 16 communicating with the inside of t...

Embodiment 2

[0044] A pressure relief valve that is easy to install, including a valve body 1, a partition 6 and a mounting block 14, the inner wall of the valve body 1 is provided with a chute 2, and the partition 6 is slidably clamped in the chute 2, the A stepped mounting hole 3 for accommodating the mounting block 14 is opened on the outer wall of one side of the valve body 1;

[0045] The partition 6 is provided with a pressure relief port 7, and the end surface of the partition 6 away from the installation hole 3 is provided with a hinged seat 8, and the hinged seat 8 is rotatably connected with a cover for blocking the pressure relief port 7 9. A first connection seat 10 is installed on the end surface of the cover 9 facing the pressure relief port 7;

[0046] The mounting block 14 is provided with a threaded hole 15, the bottom of the threaded hole 15 is provided with a through hole 16 communicating with the inside of the valve body 1, and the end surface of the mounting block 14 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com