Hollow microsphere core-shell structure wave-absorbing material as well as preparation method and application thereof

A core-shell structure and wave-absorbing material technology, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve problems such as poor impedance matching, difficulty in attenuating and consuming electromagnetic waves, and achieve the effect of reducing electromagnetic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

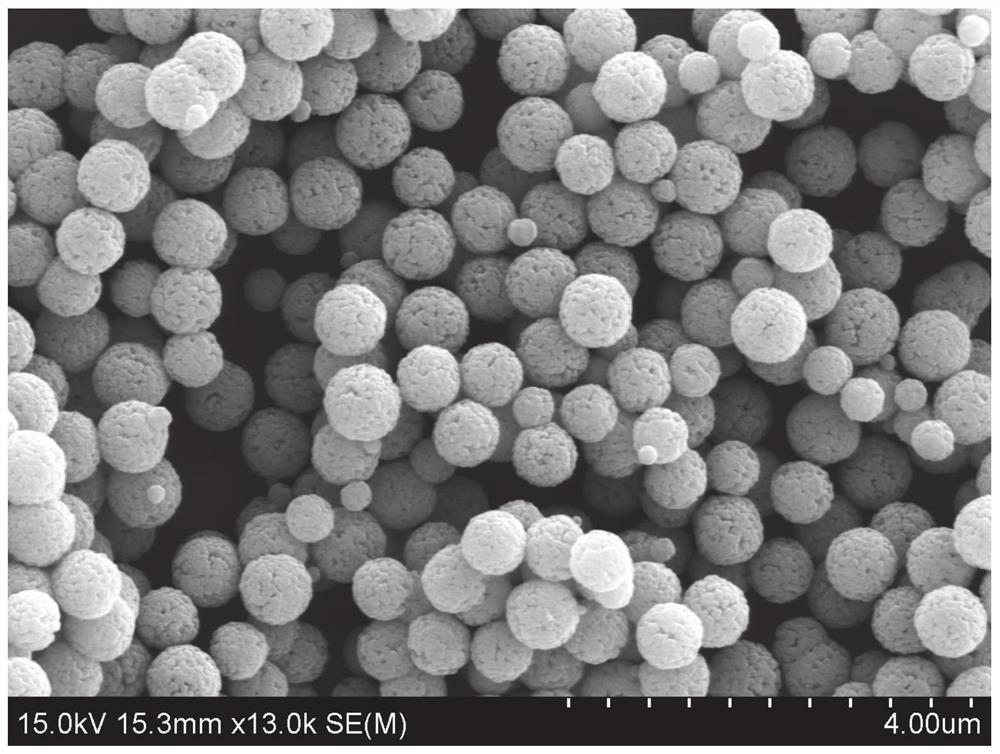

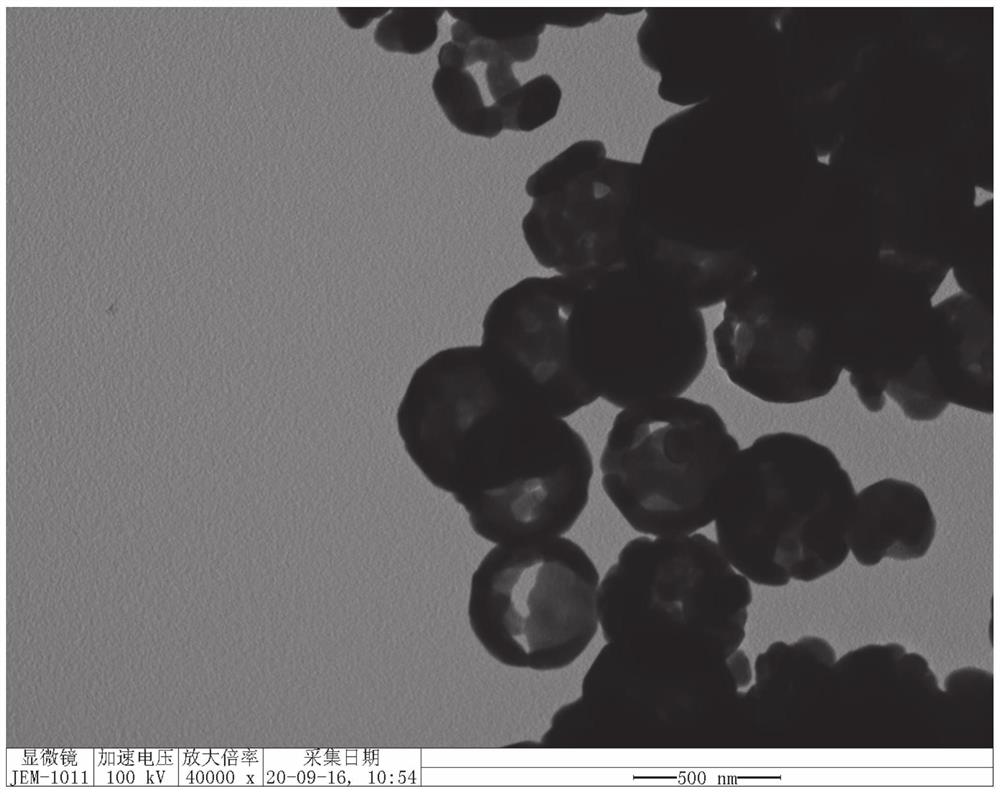

[0056] (1) Weigh 45mL of ethylene glycol, add 1.1g FeCl to it 3 ·6H 2 0, 2g polyvinylpyrrolidone (PVP) and 4g urea, the mixed solution is placed on a magnetic stirrer and stirred to transparency, then ultrasonically homogenized; the gained solution is transferred to a reaction kettle lined with polytetrafluoroethylene, Place it in an electric blower box and heat it to 200°C, keep the temperature constant for 30h, then cool it down to room temperature naturally to get Fe 3 o 4 hollow microspheres.

[0057] (2) 0.68g Zn(Ac) 2 2H 2 O and 0.1 g of Fe prepared in step (1) 3 o 4 The hollow microspheres were added to 100 mL of absolute ethanol; then 25 mL of alcohol solution containing 0.25 g of NaOH was added dropwise in a water bath at 60 °C. After the dropwise addition, the mixture was mechanically stirred for 4 hours, and the obtained product was separated from the solvent with a magnet, washed with absolute ethanol and deionized water several times, and dried. Get ZnO co...

Embodiment 2

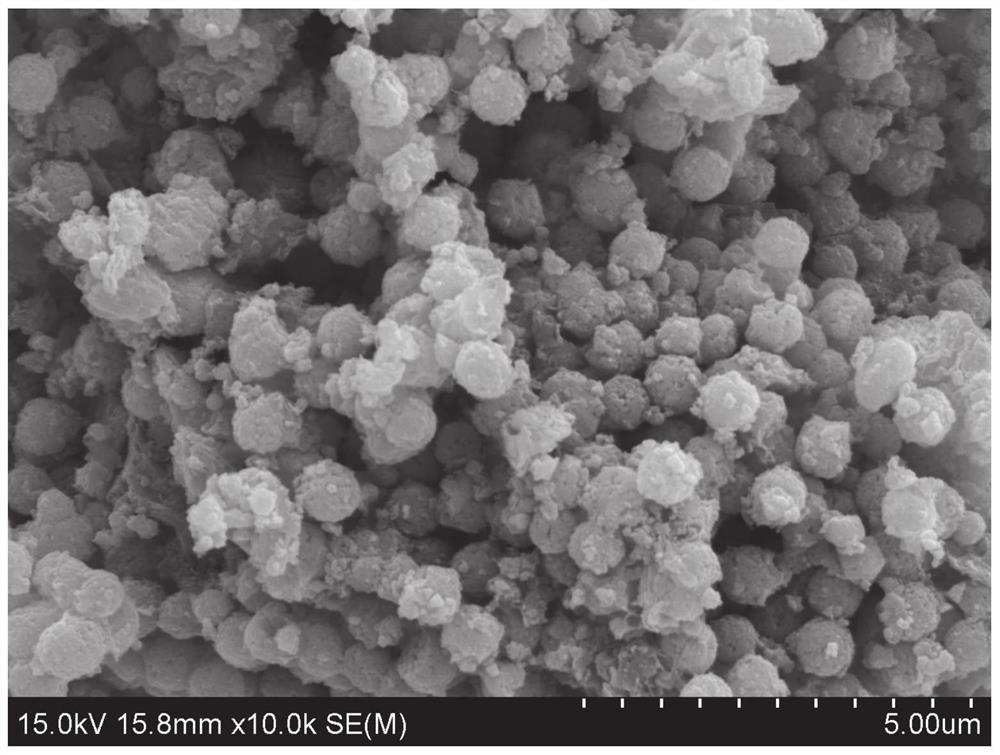

[0062] Compared with Example 1, the heating time in step (1) is 36h, and other conditions remain unchanged. get Fe 3 o 4 hollow microspheres.

[0063] The operation of step (2) is identical with embodiment 1, obtains ZnO coating Fe 3 o 4 Hollow microsphere core-shell structure material.

Embodiment 3

[0065] Compared with Example 1, the amount of urea in step (1) is changed to 6g, and other conditions remain unchanged. get Fe 3 o 4 hollow microspheres. Step (2) is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com