Electric multi-rotor unmanned aerial vehicle with mixed large and small rotors

A multi-rotor UAV and UAV technology, applied in the field of aircraft, can solve the problems of reduced response speed, increased difficulty in attitude control, and bombing, so as to make up for the reduced control performance, ensure fast response, and increase flight. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the technical invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the technical invention. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

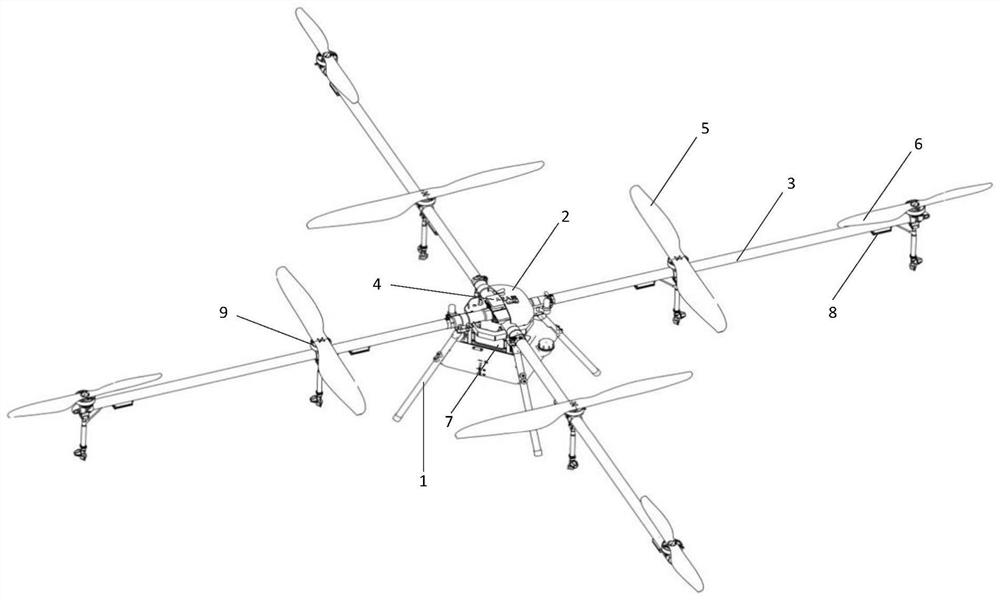

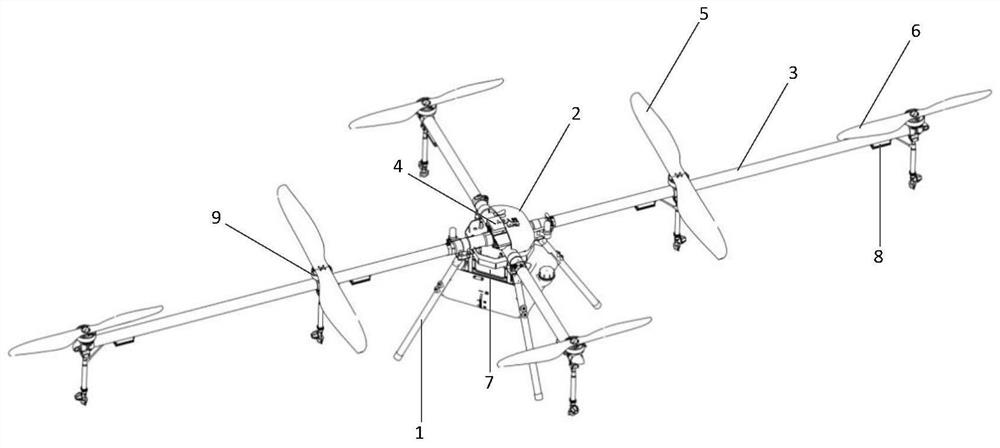

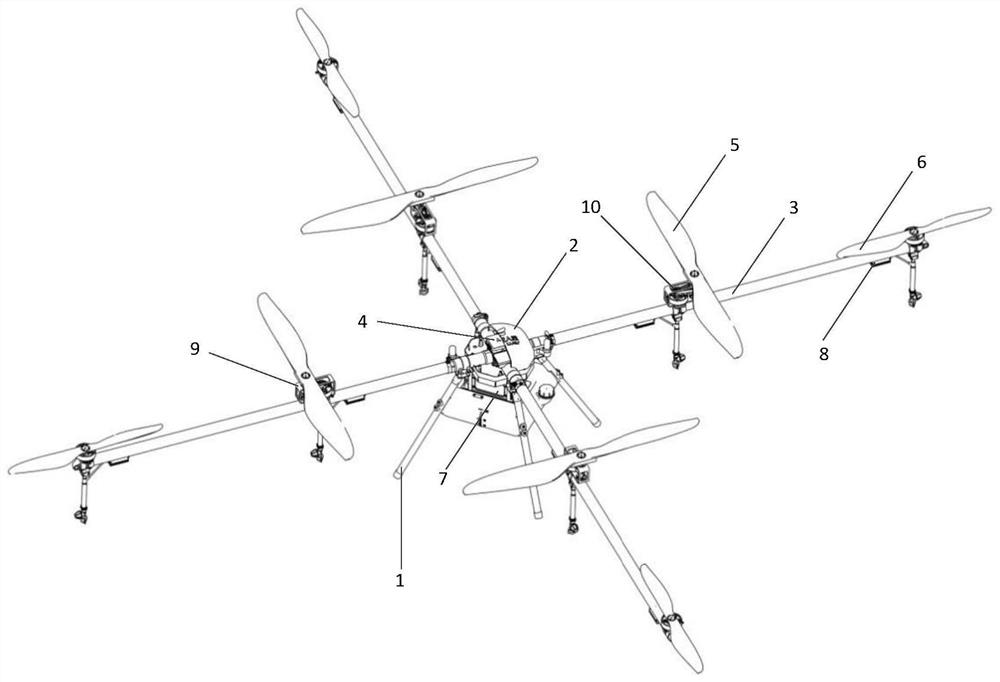

[0023] like figure 1 As shown, the present invention is a multi-rotor UAV with a mixture of large and small rotors. When the motor remains unchanged, the large rotor has a large lift and slow response, and the small rotor has a fast response and small lift. Stability control with attitude. The present invention is an eight-rotor unmanned aerial vehicle with mixed large and small rotors directly driven by large paddles, which includes: landing gear 1, cabin 2, machine arm 3, flight control system 4, four large rotors 5, four small rotors 6, Lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com