Automatic solid wheel assembling machine for production workshop

A production workshop and assembly machine technology, applied to wheel assembly equipment, wheels, vehicle parts, etc., can solve the problems of high manufacturing cost, short service life, time-consuming and labor-intensive, and achieve the effect of reducing accidental injuries to operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

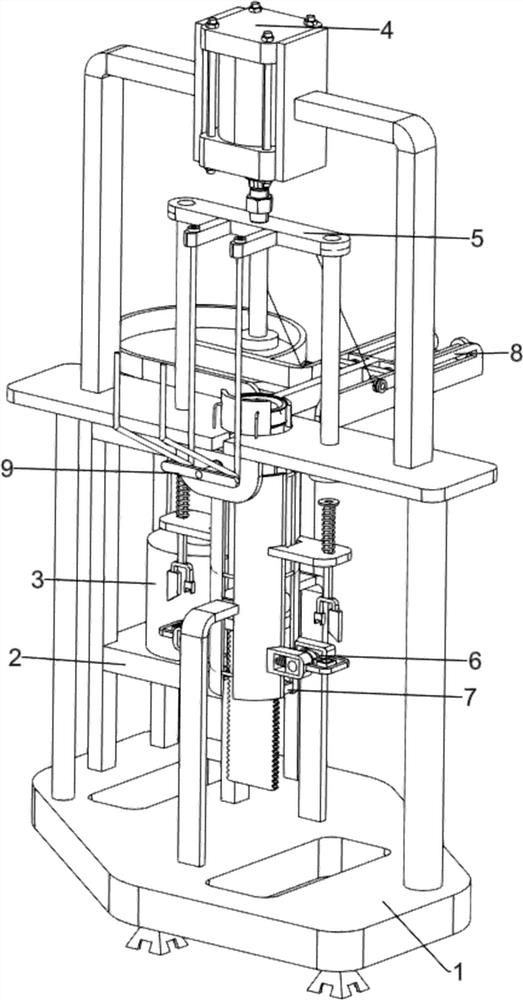

[0071] An automatic assembly machine for solid wheels in a production workshop, such as figure 1 As shown, it includes a base 1, a frame 2, a motor 3, a cylinder 4, a pressing mechanism 5, an intermittent feeding mechanism 6 and a self-locking mechanism 7; A motor 3 is installed inside, the top of the base 1 is provided with a pressing mechanism 5, the top of the pressing mechanism 5 is provided with a cylinder 4, the top of the base 1 is provided with an intermittent feeding mechanism 6, and the intermittent feeding mechanism 6 is provided with a self-locking mechanism 7.

[0072] People can use the present invention to press the axle into the inside of the solid tire. First, the operator places the solid tire inside the intermittent feeding mechanism 6, then puts the axles one by one on the pressing mechanism 5 of the equipment of the present invention, and then opens the air cylinder 4. After the cylinder 4 is turned on, it will continuously drive the telescopic rod up and ...

Embodiment 2

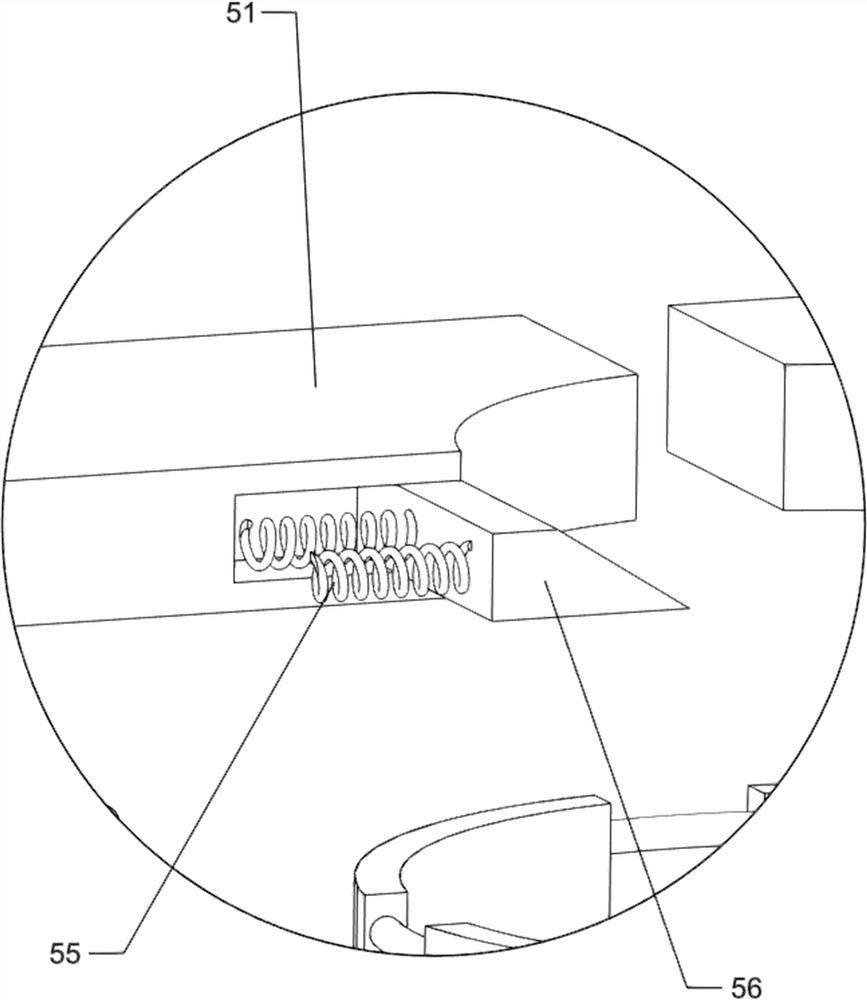

[0074] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the pressing mechanism 5 includes a base plate 51, a first connecting rod 52, a first pressing bar 53, a second pressing bar 54, a first spring 55 and a first wedge block 56, and the top of the base 1 is provided with two base plates 51. , the expansion rod of the cylinder 4 is provided with a second compression rod 54, the second compression rod 54 top is provided with a first connecting rod 52, and the bottom of the first connecting rod 52 is provided with two first compression rods 53, the first compression rod 53 Slidingly connected with the base plate 51 , the left and right base plates 51 are slidingly provided with a first wedge-shaped block 56 inside, and two first springs 55 are connected between the first wedge-shaped block 56 and the base plate 51 .

[0075] The pressing mechanism 5 can press the axle into the interior of the solid tire, and will drive the intermit...

Embodiment 3

[0081] On the basis of Example 2, such as Image 6 with Figure 7 As shown, an intermittent feeding mechanism 8 is also included, and the intermittent feeding mechanism 8 includes a second rotating shaft 81, a rotating disk 82, a guide table 83, a guide rod 84, a fourth spring 85, the first T-shaped push rod 86, a wire wheel 87, steel wire rope 88 and arc-shaped baffle 89, the output shaft of motor 3 is provided with second rotating shaft 81, and second rotating shaft 81 top is provided with turntable 82, and base plate 51 rear side is provided with guiding platform 83, and guiding platform 83 upper sliding type The first T-shaped push rod 86 is provided, and the rear side of the first T-shaped push rod 86 is provided with two guide rods 84. A fourth spring 85 is connected between the first T-shaped push rod 86 and the guide platform 83, and the guide platform 83 Two wire wheels 87 are arranged on the wire wheel 87, and a wire rope 88 is wound on the wire wheel 87. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com