Teleconverter coupling AA equipment

A technology of teleconverter and equipment, which is applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc. The unloading process is consistent and the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be further explained below in conjunction with the drawings:

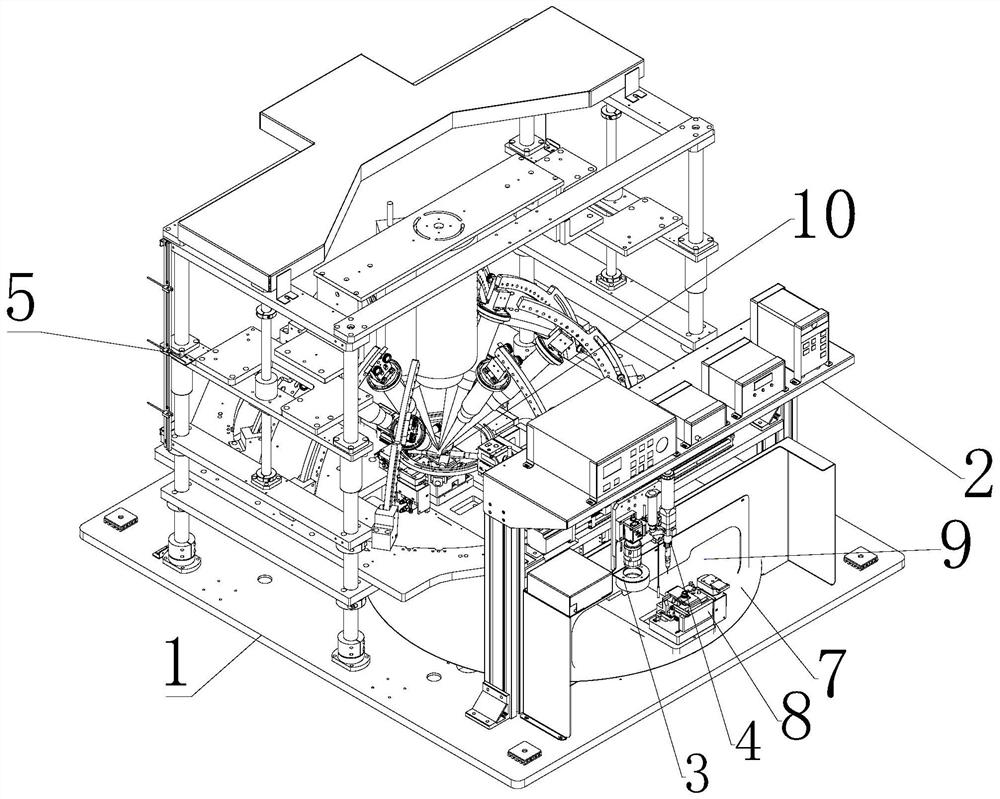

[0029]Please refer to the attached drawings, a teleconverter coupled AA equipment, including:

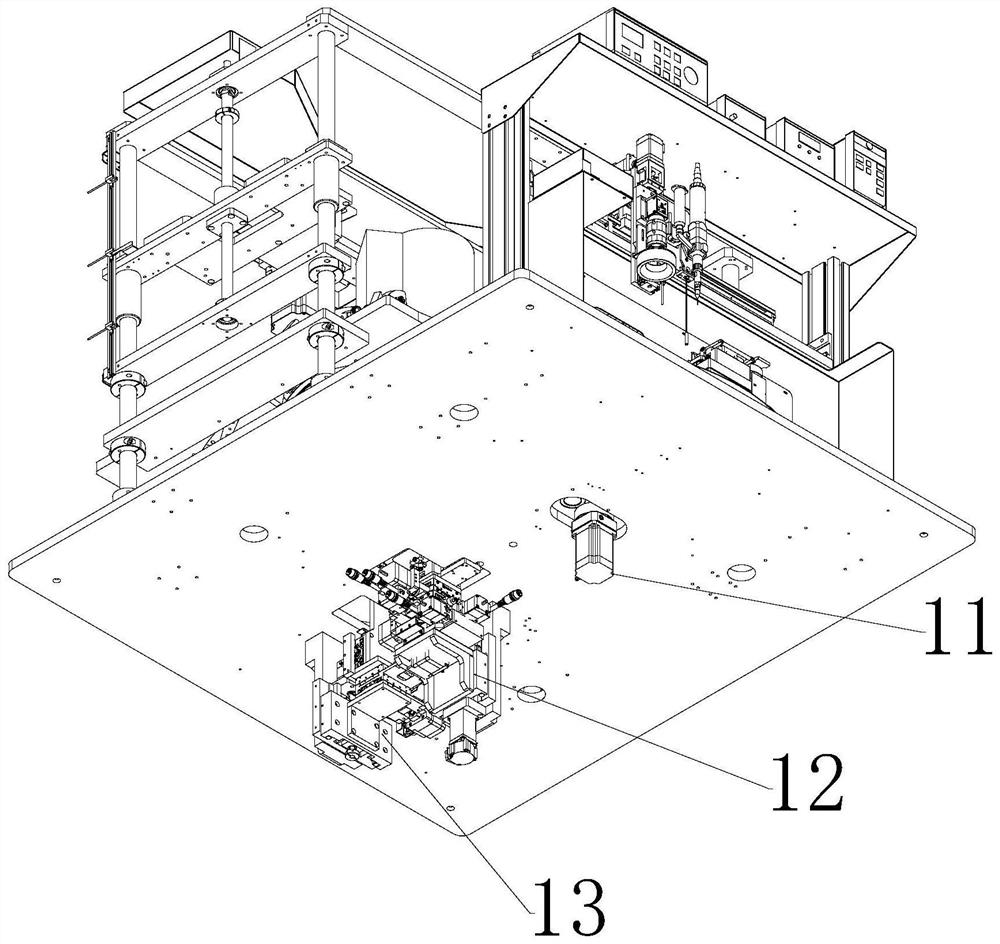

[0030]Bottom 1 and the

[0031]Mounting frame 2, the mounting frame 2 is fixedly arranged on the first side of the base plate 12, the mounting frame is provided with a CDD detection assembly 3 and a dispensing assembly 4.

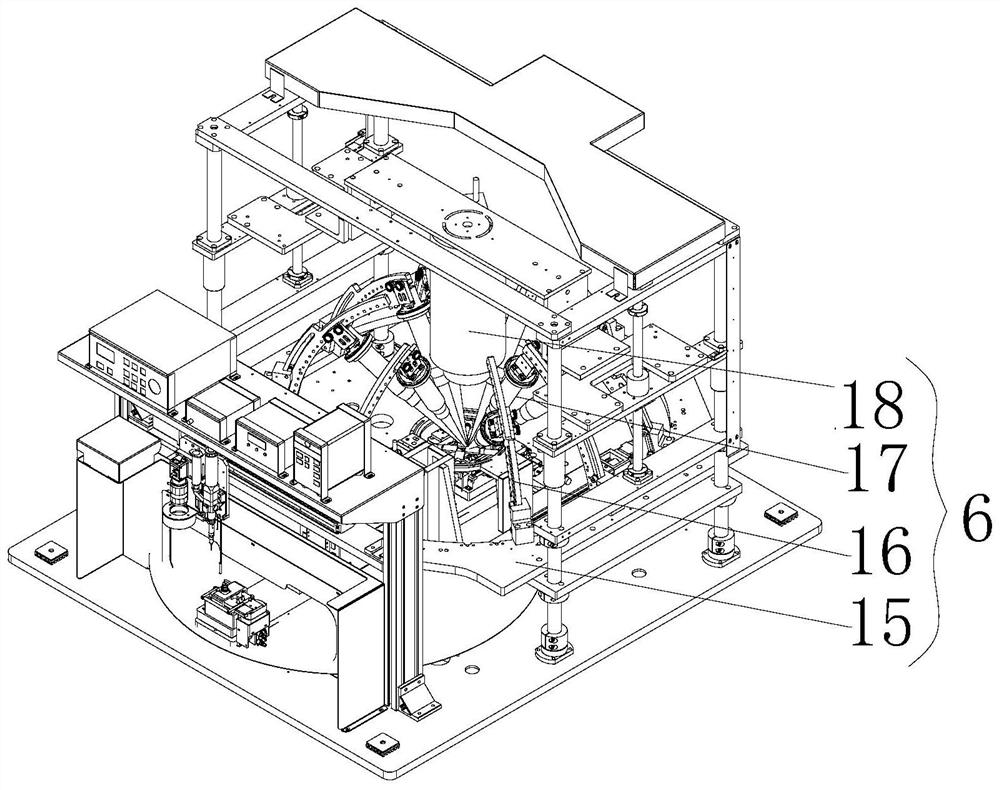

[0032]The liftable bracket 5 is arranged on the second side of the bottom plate 1, the parallel light tube assembly 6 is arranged on the liftable bracket 5, and the UV curing assembly 14 is also arranged on the liftable bracket 5.

[0033]The rotating work plate 7 is rotatably arranged on the bottom plate 1. The top surface of the rotating work plate 7 is provided with two jigs 8 symmetrically along the diameter. The rotating work plate 7 has two Station, the two stations are the first station 9 located under the mounting frame 2 and the second station 10 located on the liftable bracket 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com