Processing method of instant abalones

A processing method and abalone technology, which is applied in the field of instant abalone processing, can solve the problems of soft and rotten product texture, low moisture content, and poor product taste, and achieve the effects of reducing thermal sterilization intensity, inhibiting germination, and reducing sterilization intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

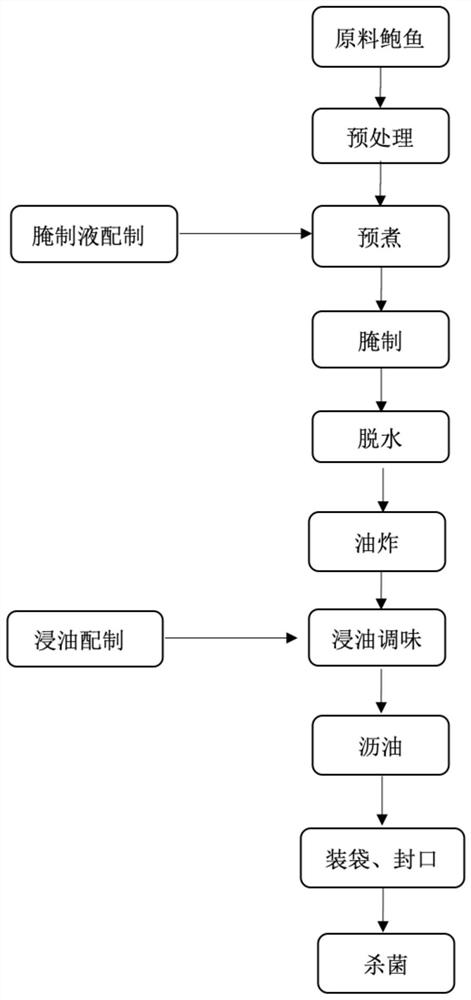

Method used

Image

Examples

Embodiment 1

[0027] (1) Abalone pretreatment: Frozen abalone is thawed in running water or in a thawing room, selected to remove defective parts, trimmed and cleaned;

[0028] (2) Pre-cooking: After the pickling solution is boiled, add the abalone to the pickling solution according to the mass ratio of 1:1, cook for 3 minutes, then remove the abalone and cool to below 15°C;

[0029] (3) Pickling: marinate the precooked abalone in the pickling solution at 4°C for 12 hours according to the mass ratio of raw materials: pickling solution = 1:2 (m / m), remove the abalone, and drain;

[0030] (4) Dehydration: spread the marinated abalone evenly in a single layer on the baking rack, dehydrate at 50°C for about 1.5h, and cool to room temperature;

[0031] (5) Frying: use vegetable oil such as soybean oil, and fry for 1 minute at an oil temperature of about 160°C;

[0032] (6) Oil immersion seasoning: add 2g / kg nisin to the prepared seasoning oil filtrate and mix evenly; abalone after drying accord...

Embodiment 2

[0037] (1) Thawing and pretreatment: Frozen abalone is thawed in running water or in a thawing room, selected to remove defective parts, trimmed and cleaned;

[0038] (2) Pre-cooking: After the pickling solution is boiled, add abalone to the pickling solution at a mass ratio of 1:1, cook for 3 minutes, then remove the abalone and cool to below 15°C;

[0039](3) Pickling: marinate the precooked abalone in the pickling solution at 4°C for 12 hours according to the mass ratio of raw materials: pickling solution = 1:2 (m / m), remove the abalone, and drain;

[0040] (4) Dehydration: spread the marinated abalone evenly in a single layer on the baking rack, dehydrate at 50°C for about 1.5h, and cool to room temperature;

[0041] (5) Frying: use vegetable oil such as soybean oil, and fry for 1 minute at an oil temperature of about 160°C;

[0042] (6) Oil immersion seasoning: add 2g / kg nisin to the prepared seasoning oil filtrate and mix evenly; abalone after drying according to mass r...

Embodiment 3

[0047] (1) Thawing and pretreatment: Frozen abalone is thawed in running water or in a thawing room, selected to remove defective parts, trimmed and cleaned;

[0048] (2) Pre-cooking: After the pickling solution is boiled, add abalone to the pickling solution at a mass ratio of 1:1, cook for 3 minutes, then remove the abalone and cool to below 15°C;

[0049] (3) Pickling: marinate the precooked abalone in the pickling solution at 4°C for 12 hours according to the mass ratio of raw materials: pickling solution = 1:2 (m / m), remove the abalone, and drain;

[0050] (4) Dehydration: spread the marinated abalone evenly in a single layer on the baking rack, dehydrate at 50°C for about 1.5h, and cool to room temperature;

[0051] (5) Frying: use vegetable oil such as soybean oil, and fry for 1 minute at an oil temperature of about 160°C;

[0052] (6) Oil immersion seasoning: add 2g / kg nisin to the prepared seasoning oil filtrate and mix evenly; abalone after drying according to mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com