Wiring terminal connector

A technology of terminal blocks and connectors, which is applied in the direction of connection, parts of connection devices, contact parts, etc., can solve problems such as short circuit and complex structure, and achieve the effects of preventing accidental touch, convenient wire installation, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

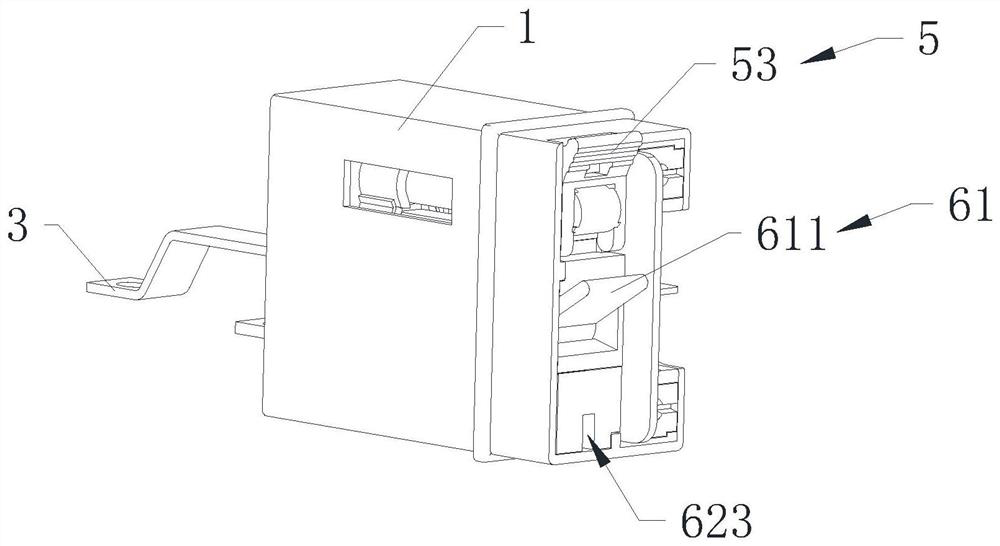

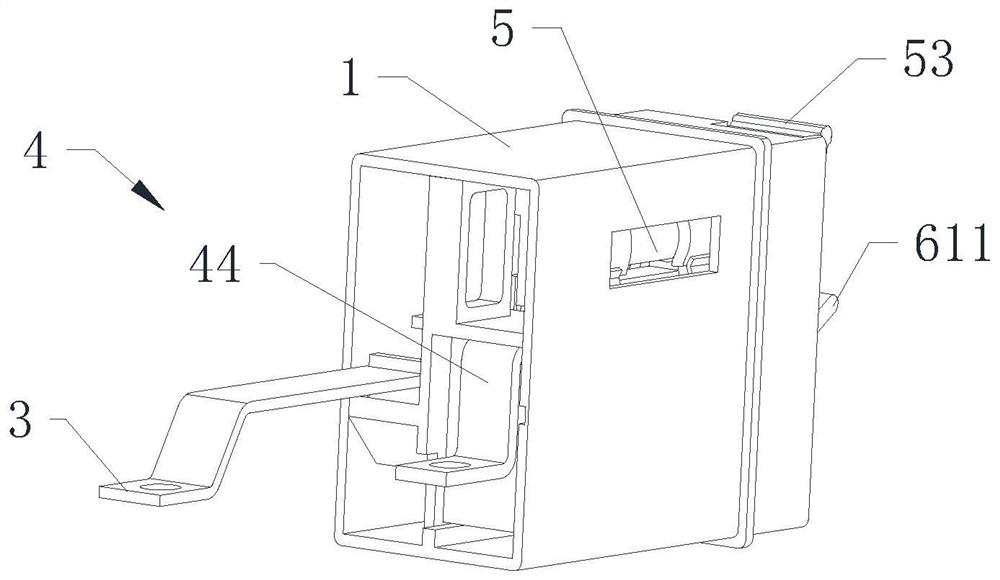

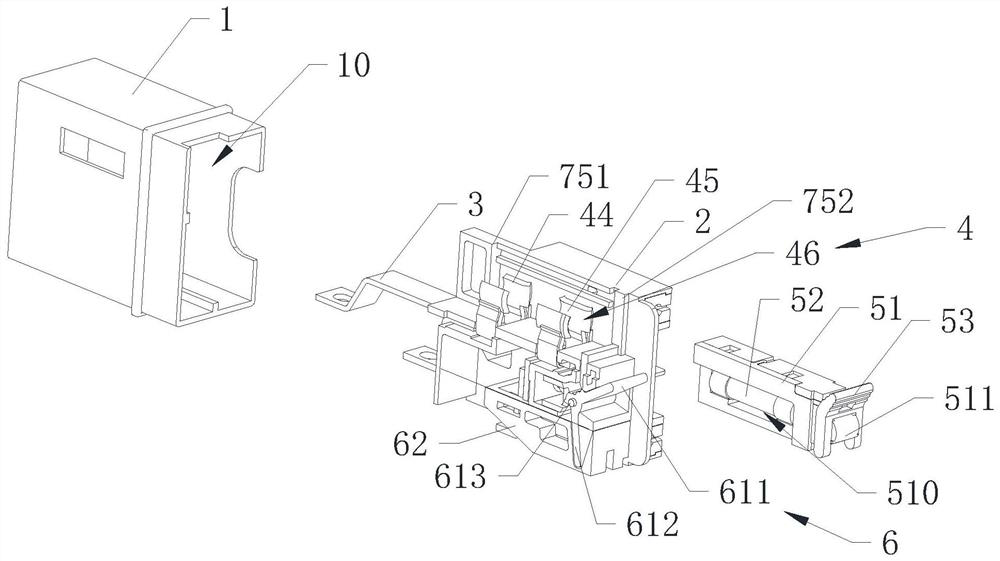

[0059] Reference manual attached Figure 1 to Figure 13 , The present invention provides a terminal connector, the terminal connector is simple in structure, small in size and easy to use.

[0060] Reference manual attached figure 1 , figure 2 , image 3 as well as Figure 4 , specifically, the terminal connector includes a connector housing 1 , a separation seat 2 , a first conductive member 3 , a second conductive component 4 , a fuse 5 and a switch component 6 . The connector housing 1 surrounds an accommodating cavity 10 . The separation seat 2 is installed in the accommodation chamber 10 and divides the accommodation chamber 10 into an operation chamber 11 and a wiring chamber 12 . The first conductive member 3 is installed in the wiring cavity 12 for electrical connection with the first electric wire.

[0061] The second conductive component 4 includes a second conductive member 41 , a movable contact conductive member 42 , a static contact conductive member 43 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com