Fire control box test system and test method

A test system and fire control box technology, applied in the field of inspection and detection, can solve problems such as slow detection speed, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

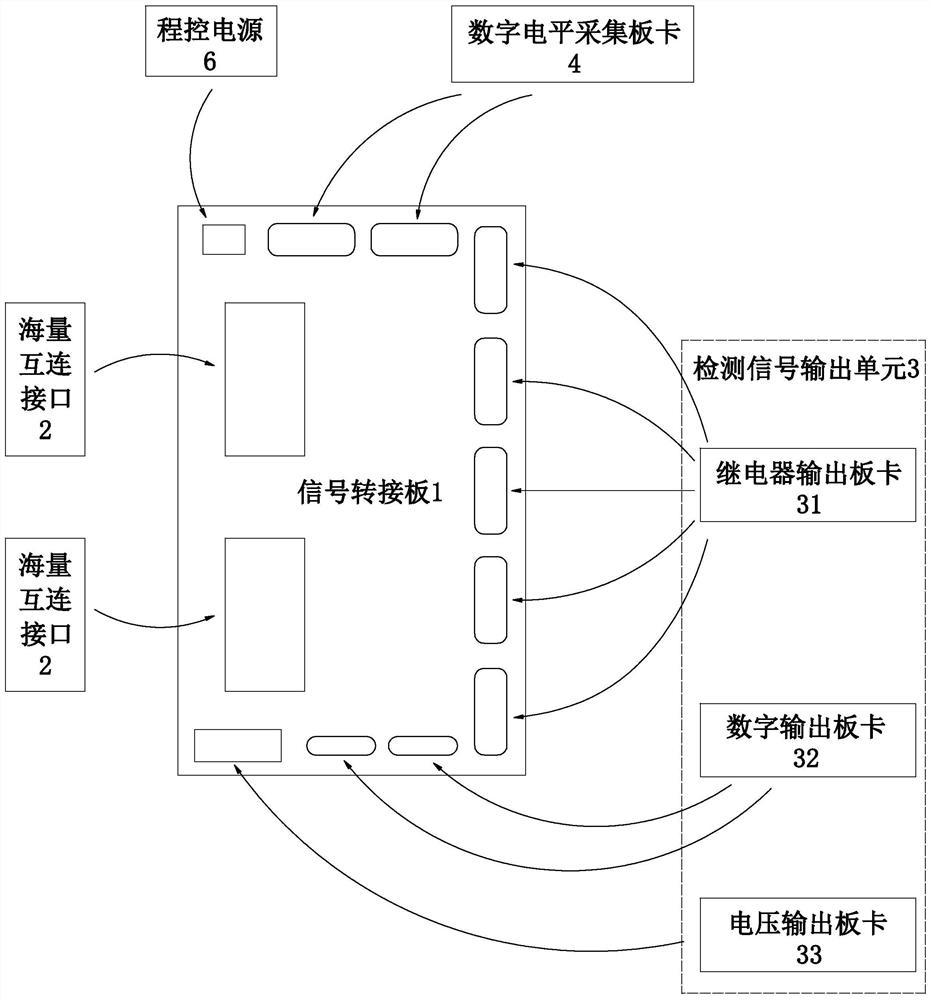

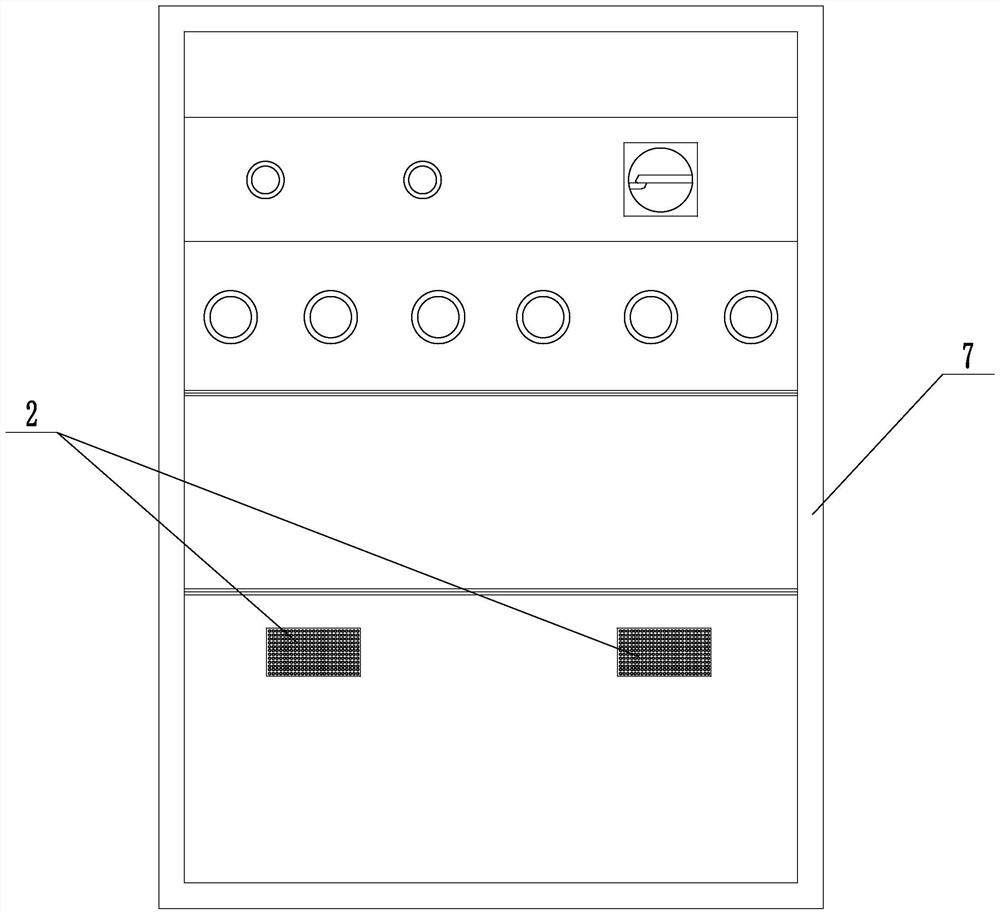

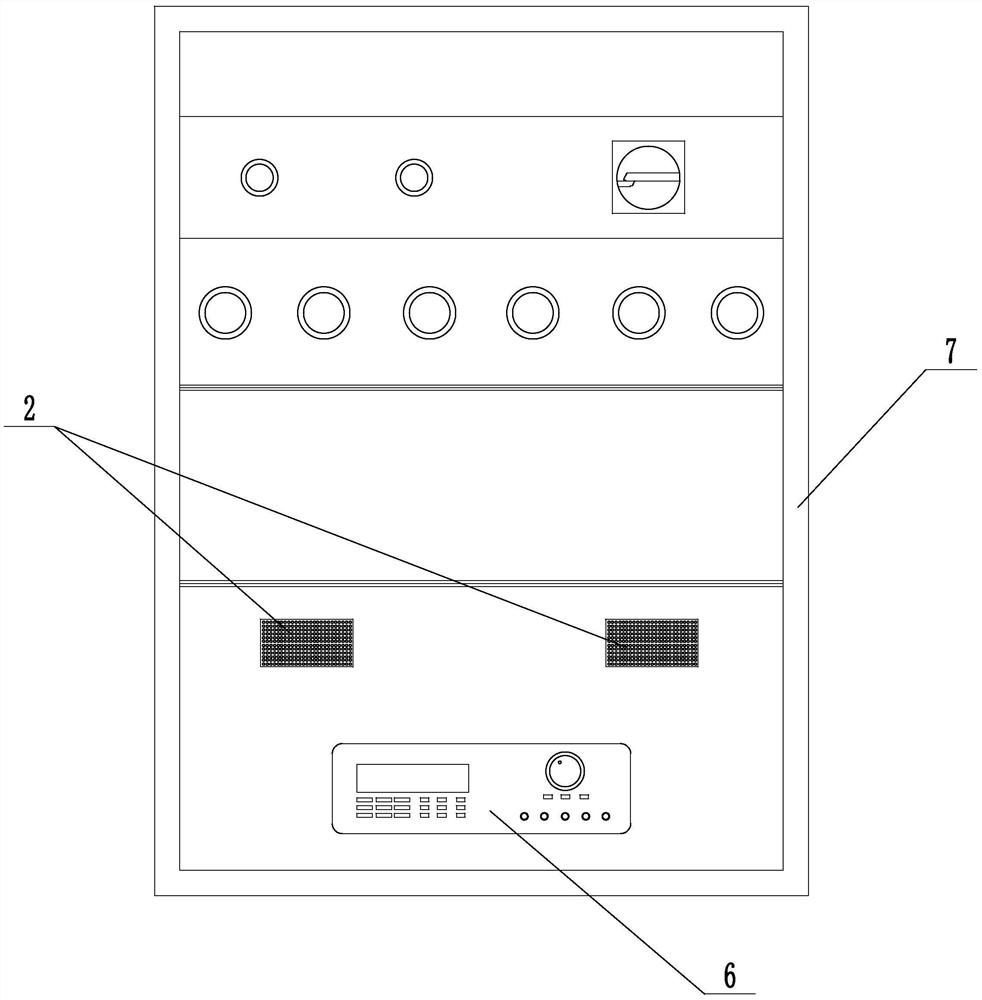

[0046] The technical solution in this application will be described in further detail below in conjunction with the accompanying drawings.

[0047] First, briefly introduce the testing process of the fire control box. The fire control box test includes the following test items:

[0048] Action voltage detection: Under standard atmospheric conditions, the products are connected to the working voltage respectively, and the action voltage value output by the fire control box is measured, and the value should be within the allowable range of error.

[0049] Low temperature test: Keep the standard detection time in a low temperature environment in the non-energized state, then turn on the power, and measure the operating voltage value after a period of time.

[0050] High temperature test: keep the standard detection time in a high temperature environment in a non-energized state, then turn on the power, and measure the operating voltage value after a period of time.

[0051] Ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com