Device for testing gas permeability of alkaline cured sample under influence of carbonization and operation method

A gas permeability and test device technology, which is applied in the field of gas permeability test devices, can solve the problems of unsatisfactory testing, inability to switch back and forth, and difficulty in satisfying samples, etc., to eliminate the influence of water immersion and unsaturated gas, and the structure of the device Compact and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

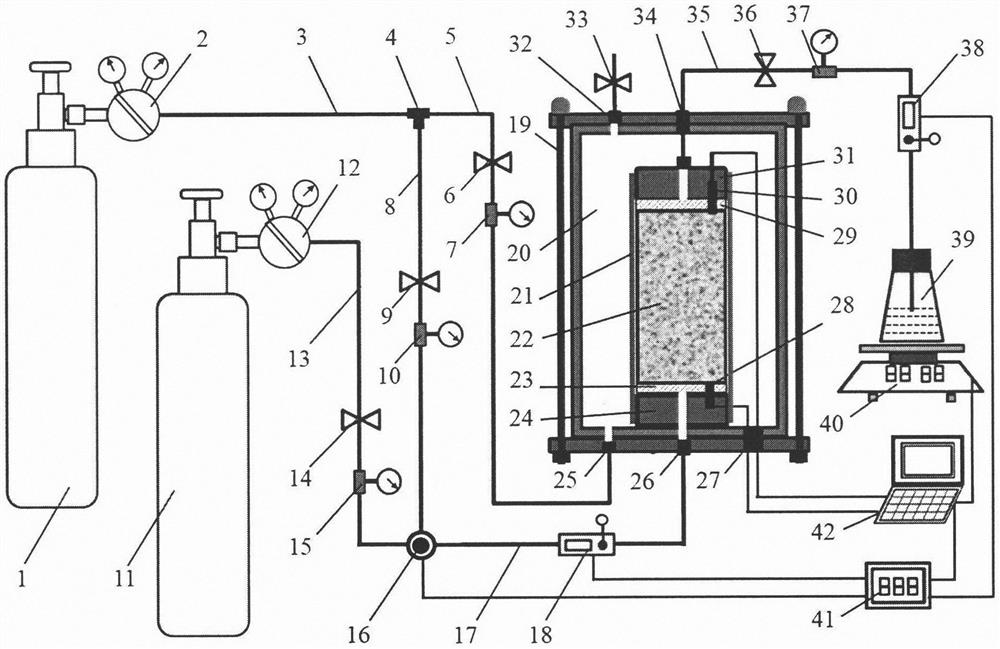

[0054]In order to more easily understand the operation of the present invention, according to the sample and curing agent material type, the required air pressure and ventilation time for complete carbonization and other factors, select the time period of ventilation carbonization and gas infiltration such as t1, T2, T3, T4, T5, T6……. If the sample is silt or silty clay with relatively good permeability, the aeration time required to complete the complete carbonization is short, which can be completed within 6 hours. At this time, the aeration pressure can be selected from 25-200kPa during the test. , Aeration and carbonization time is 10-15min, without aeration for 5min, gas infiltration time is 15-30min. If the sample is a clay with poor permeability, the aeration time required to complete the complete carbonization is longer, generally within 12 hours. At this time, the aeration pressure can be selected to be 200-400kPa and the carbonization time is 20-30min. Cure without ventila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com