Automatic coring and cutting device and method

A cutting device and automatic technology, applied in the test field, can solve problems such as difficult process, achieve the effect of improving transfer efficiency, low installation difficulty, and reducing the length of transfer path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

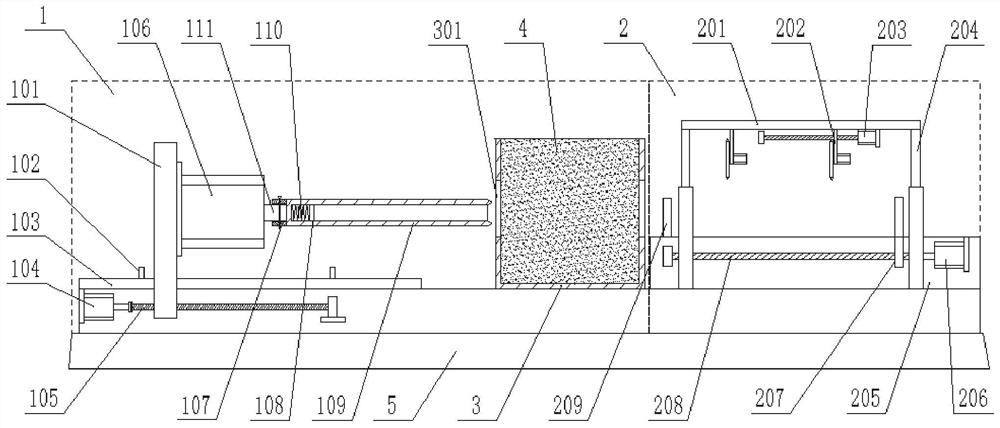

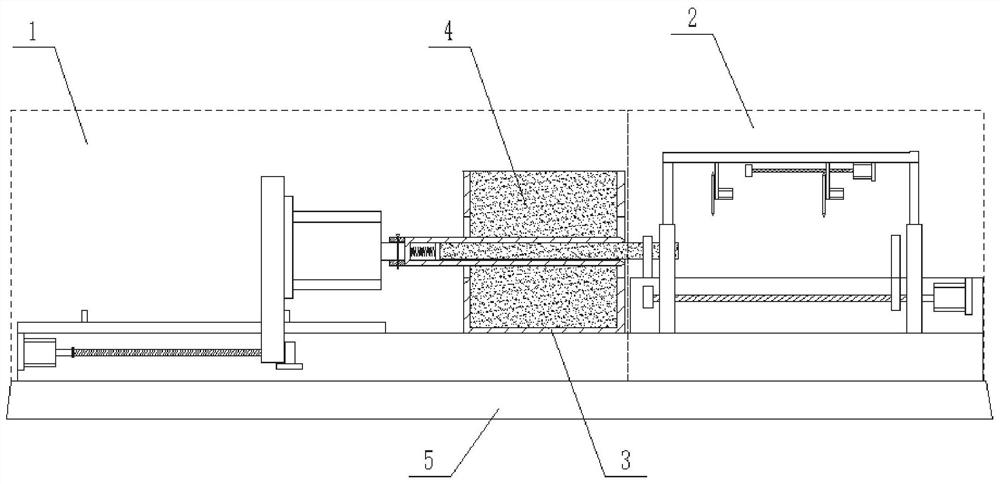

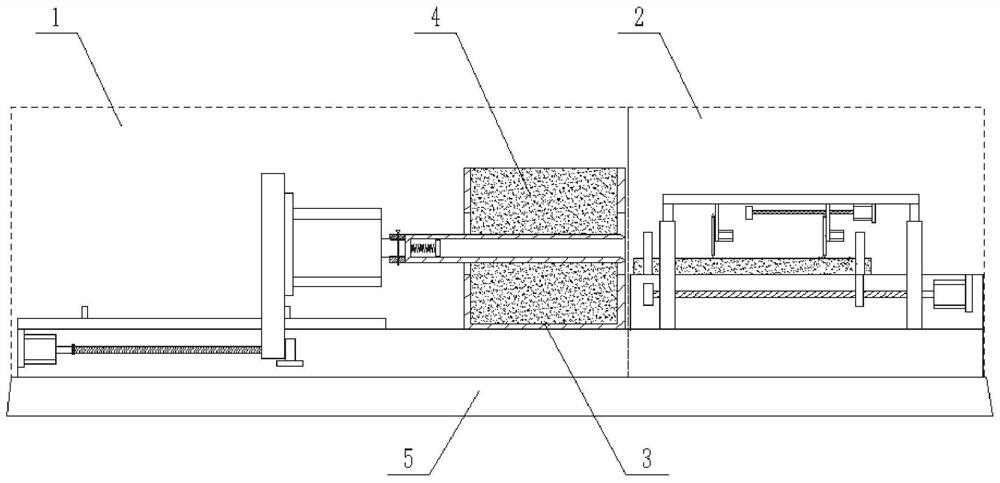

[0035] Such as Figure 1-Figure 3 As shown, this embodiment provides an automatic coring and cutting device, which includes a test piece box 3 for holding a test piece 4 , and a coring mechanism 1 and a cutting mechanism 2 respectively arranged on both sides of the test piece box 3 .

[0036] The coring mechanism 1 includes a drill bit 109 with a horizontal axis of rotation. The drill bit 109 can reciprocate and linearly move along its own axis of rotation, and extend into the test piece 4 to drill core samples. The test piece box 3 is close to the coring mechanism 1 and the cutting mechanism 2. The two sides of each have an area without an outer wall, so as to be suitable for the drilling of the drill bit 109 assembly; the drill bit 109 can penetrate the test piece box 3 and the test piece 4 along its own axis direction, so that the head of the drill bit 109 extends into the cutting mechanism 2 sides.

[0037] It can be understood that, in this embodiment, the drill bit 109 ...

Embodiment 2

[0062] This embodiment provides an automatic coring and cutting method, using the automatic coring and cutting device described in Embodiment 1, comprising the following steps:

[0063] Step 1: Reset the coring mechanism 1 and the cutting mechanism 2;

[0064] Step 2; Place the test piece 4 in the test piece box 3, then start the equipment;

[0065] Step 3: The drill bit 109 moves toward the test piece box 3 during its own rotation, and gradually extends into the test piece box 3 to drill a core sample;

[0066] Step 4: When the drill bit 109 completely penetrates the test piece box 3, the head of the drill bit 109 extends above the cutting mechanism 2, and the ejector assembly ejects the core sample to a set length;

[0067] Step 5: the sliding fixture 207 slides to the head position of the drill bit 109, the sliding fixture 207 clamps one end of the core sample, and then moves away from the drill bit 109, so that the core sample is moved to the cutting station of the cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com