Drill barrel structure of rotary drilling rig

A technology of rotary drilling rigs and drill barrels, which is applied in earthwork drilling, building construction, boreholes/well components, etc., which can solve problems such as low efficiency, noise pollution in the surrounding environment, troublesome operation, etc., and improve the quality of soil unloading , reduce noise pollution, and avoid personnel waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

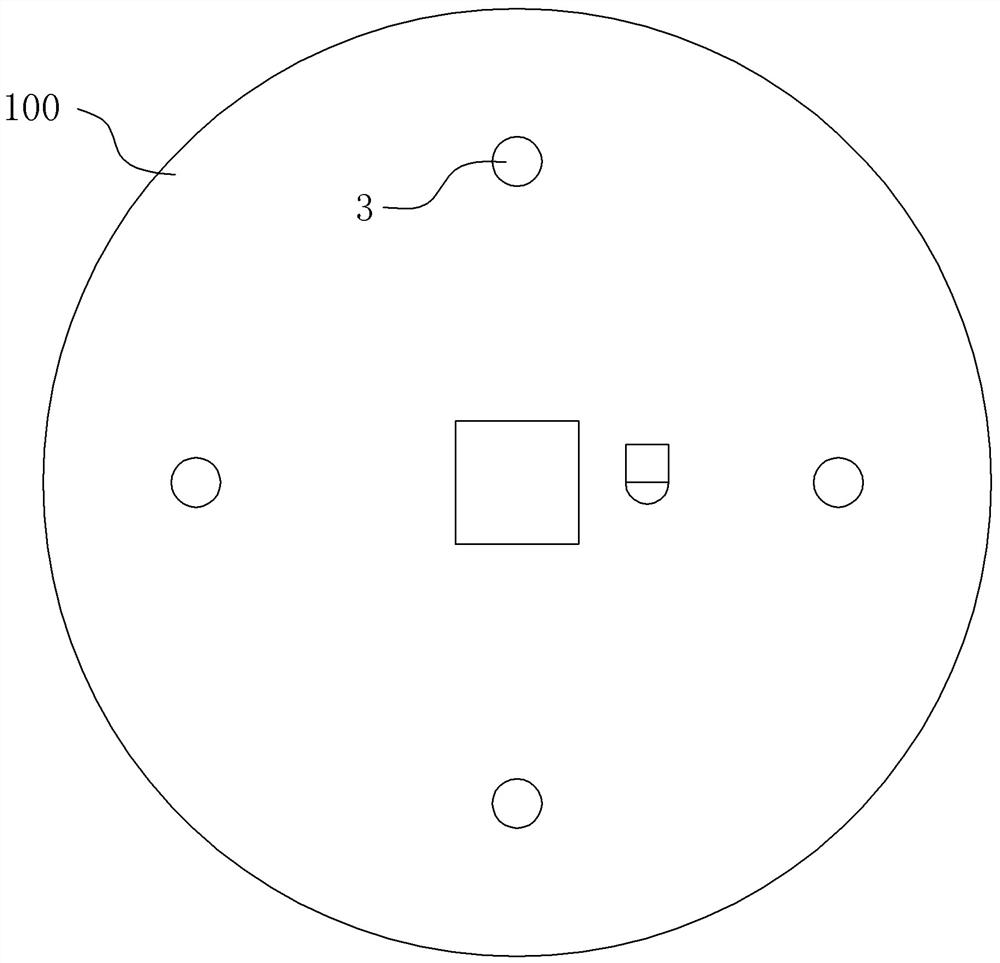

[0009] A drill barrel structure for a rotary drilling rig, including a piston 1 for pushing soil and a push rod 2 for driving the piston. The piston is arranged at the end of the drill barrel facing away from the opening. The number of push rods passing through the positioning holes 3 is consistent with the positioning holes, and one end of each push rod passes through each positioning hole and is fixedly connected with the piston, and the other end of the push rod is arranged below the power platen.

[0010] Such as Figure 1-3 As shown, the drill barrel structure of the rotary drilling rig is installed on the drill barrel 100 of the rotary drilling rig and below the power platen 200 . Driven by the drill pipe, the drill pipe and the drill bit inside extend into the soil layer for soil excavation. After a certain amount of soil is excavated or penetrated to a certain depth, the drill pipe drives the drill pipe to rise, and the top of the push rod There is a certain distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com