A post-synthesis modified mof-pc material and its preparation method and application

A MOF-PC, MOF technology, applied in the field of fluorescent probes, can solve the problems of long detection time, low sensitivity, and lack of active sites for MOF fluorescence sensing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention firstly provides a kind of preparation method of post-synthesis modified MOF-PC material, the method comprises:

[0035] Step 1: Synthesis of MOF materials

[0036] Add zirconium chloride to the N,N-dimethylformamide solvent, add hydrochloric acid (or acetic acid) dropwise, and ultrasonically dissolve the solid zirconium chloride. The ultrasonic time is preferably 10-15 minutes, and then add 2- N, N-dimethylformamide solution of aminoterephthalic acid, mix and stir evenly, the stirring time is preferably 20-25min; react at a constant temperature of 80°C to 120°C, and the reaction time is preferably 20-20min 24h; After the reaction is completed, centrifuge, wash, and vacuum-dry to obtain light yellow MOF solid powder; the mol ratio of the zirconium chloride and 2-aminoterephthalic acid is preferably (0.9~1.1):(1.3~1.6) , more preferably 1.08:1.5.

[0037] Step 2: Post-synthesis modification of MOF materials

[0038] Add the MOF solid powder prepa...

Embodiment 1

[0047] (1) Synthesis of MOF materials: ZrCl 4 (1.08mmol) was dissolved in 10mL N,N-dimethylformamide, 2mL hydrochloric acid was added, ultrasonicated for 10min, and 20mL N,N-dimethylformamide containing 2-aminoterephthalic acid (1.5mmol) was added solution, mixed at room temperature and stirred for 20 minutes, then moved the mixed solution into a reaction kettle, and placed the reaction kettle in an oven at 80°C for a constant temperature reaction for 24 hours. After the reaction was completed, the sample was centrifuged, washed, and vacuum-dried to obtain a light yellow solid powder.

[0048] (2) Post-synthesis modification of MOF materials: Weigh 100 mg of MOF materials and dissolve them in 8 mL of acetonitrile solvent, stir at room temperature for 20 min, then add 2-PC (0.6 mmol) and 10 μL of acetic acid, and react at a constant temperature of 45 °C for 48 h. After cooling, filtering, washing and vacuum drying, the modified MOF-PC material was synthesized.

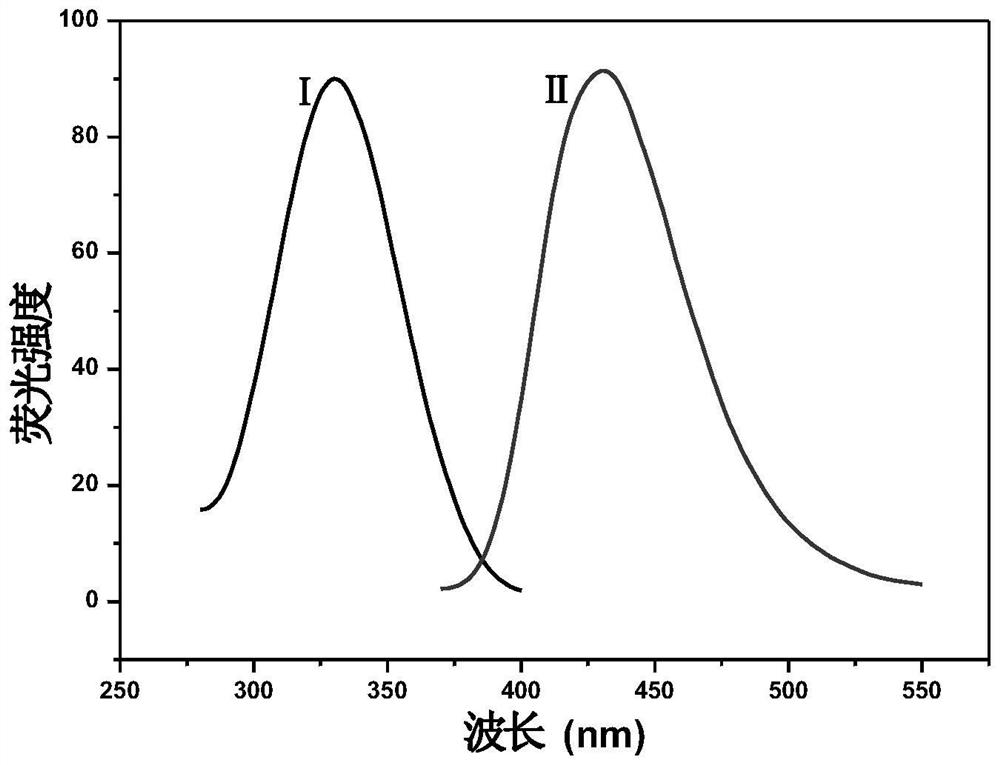

[0049] Fluores...

Embodiment 2

[0051] (1) Synthesis of MOF materials: ZrCl 4 (1.08mmol) was dissolved in 10mL N,N-dimethylformamide, 2mL hydrochloric acid was added, ultrasonicated for 10min, and 20mL N,N-dimethylformamide containing 2-aminoterephthalic acid (1.5mmol) was added solution, mixed at room temperature and stirred for 20 minutes, then moved the mixed solution into a reaction kettle, and placed the reaction kettle in an oven at 80°C for a constant temperature reaction for 24 hours. After the reaction was completed, the sample was centrifuged, washed, and vacuum-dried to obtain a light yellow solid powder.

[0052] (2) Post-synthesis modification of MOF materials: Weigh 100 mg of MOF materials and dissolve them in 8 mL of ethanol solvent, stir at room temperature for 20 min, then add 2-PC (0.6 mmol) and 10 μL of acetic acid, and react at a constant temperature of 45 °C for 48 h. After cooling, filtering, washing and vacuum drying, the modified MOF-PC material was synthesized.

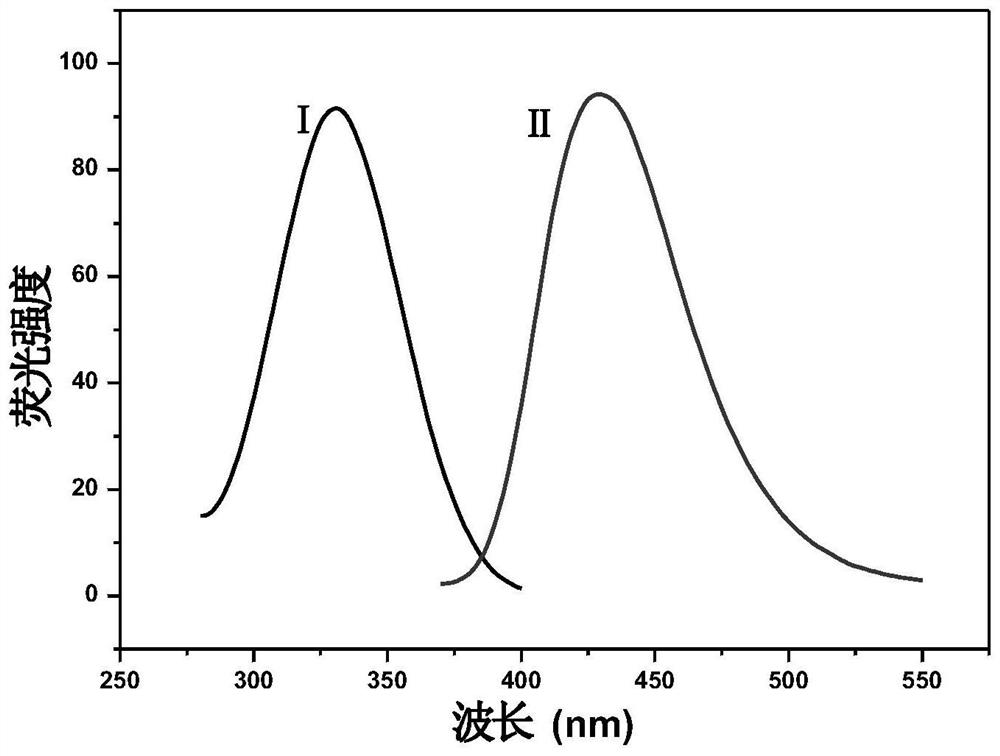

[0053] Fluorescence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com