A laser shot peening-shape correction method and its integrated device for ring parts

A technology of laser shot peening and ring parts, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of inappropriate mass production, limited objects and scope, cumbersome clamping, etc., to achieve accuracy And the effect of high practicability, high precision, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

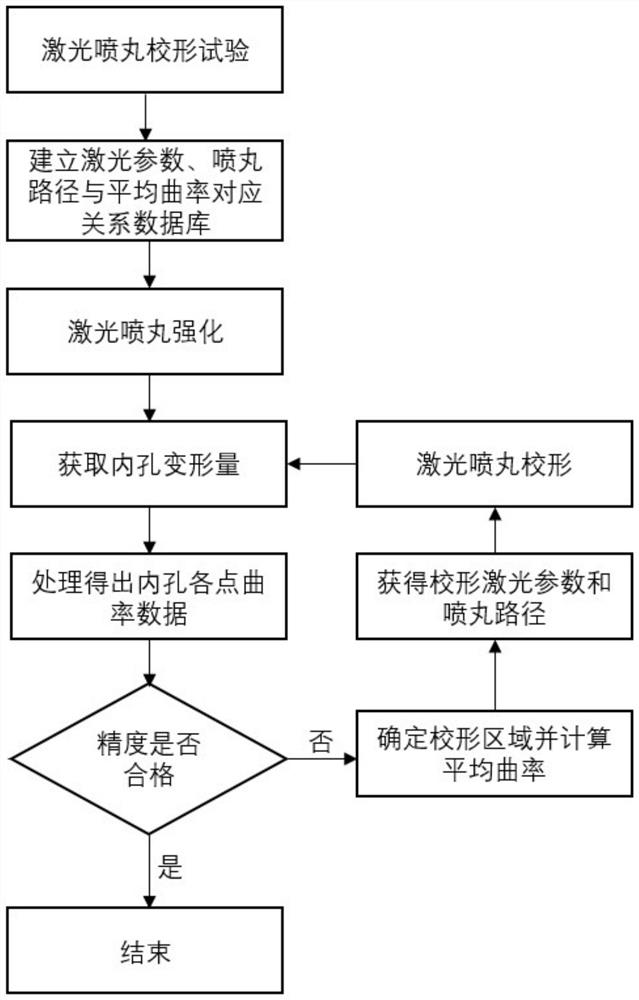

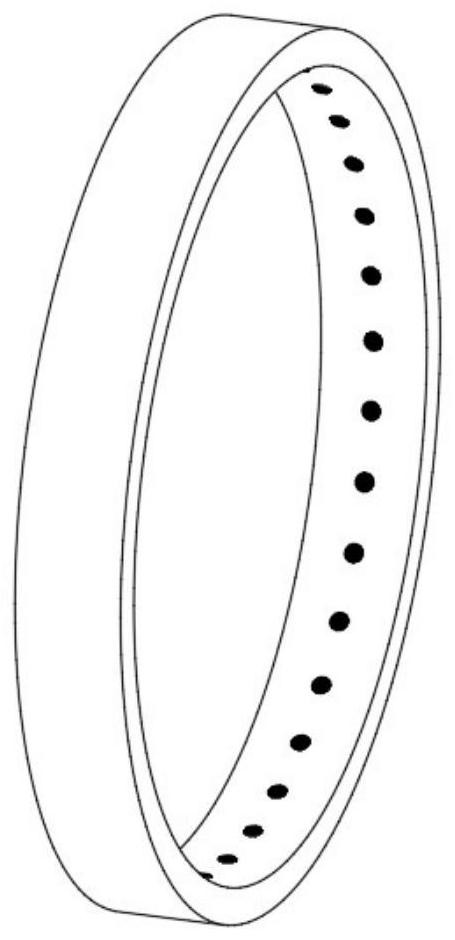

[0039] like figure 1 As shown, the laser shot peening-shape correction method for annular parts according to the present invention includes the following steps:

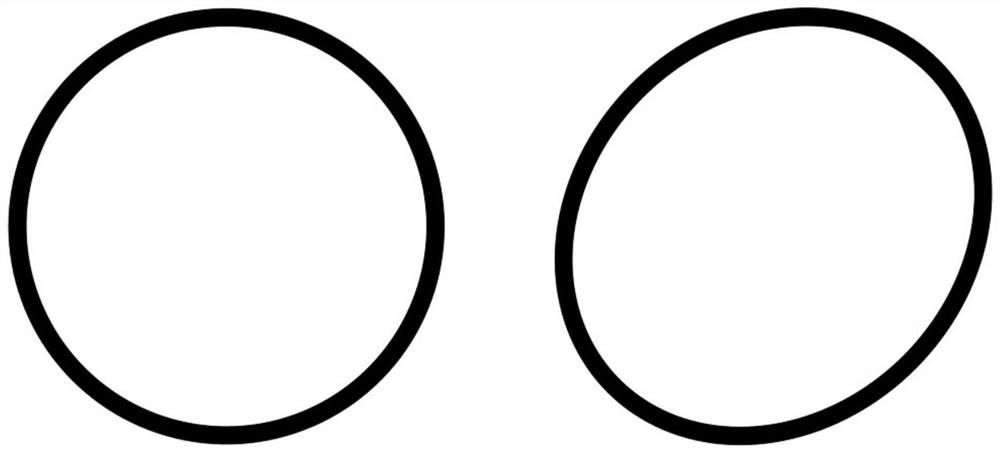

[0040] Step 1: Obtain the average curvature change data of the shape correction area through the laser shot peening shape correction test, and establish a database of the correspondence between laser parameters, shot peening paths and average curvature; the laser parameters and shot peening paths are adapted to the shape correction requirements of ring parts ;

[0041] Step 2: Select laser parameters for shot peening according to the residual compressive stress strengthening requirements of the ring parts, and at the same time, the industrial camera 9 detects the deformation of the inner hole after shot peening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com