Oil-immersed transformer end insulation automatic bonding machine

An oil-immersed transformer and terminal insulation technology, which is applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of large iron core, waste of time, and inconvenient pasting of insulating paper, so as to save manpower, paste simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

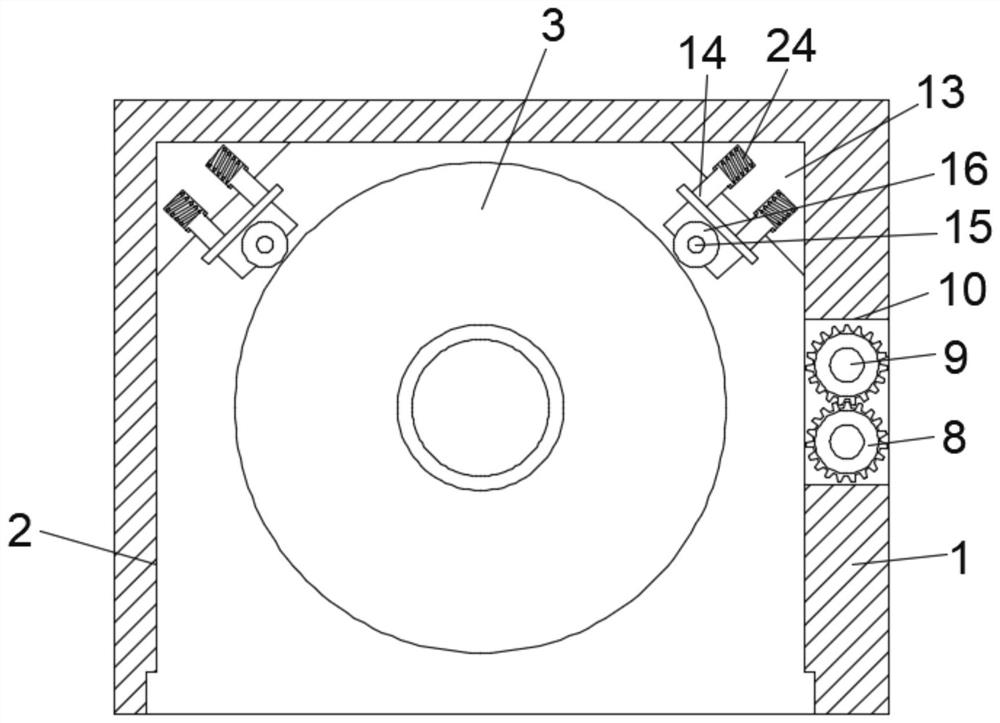

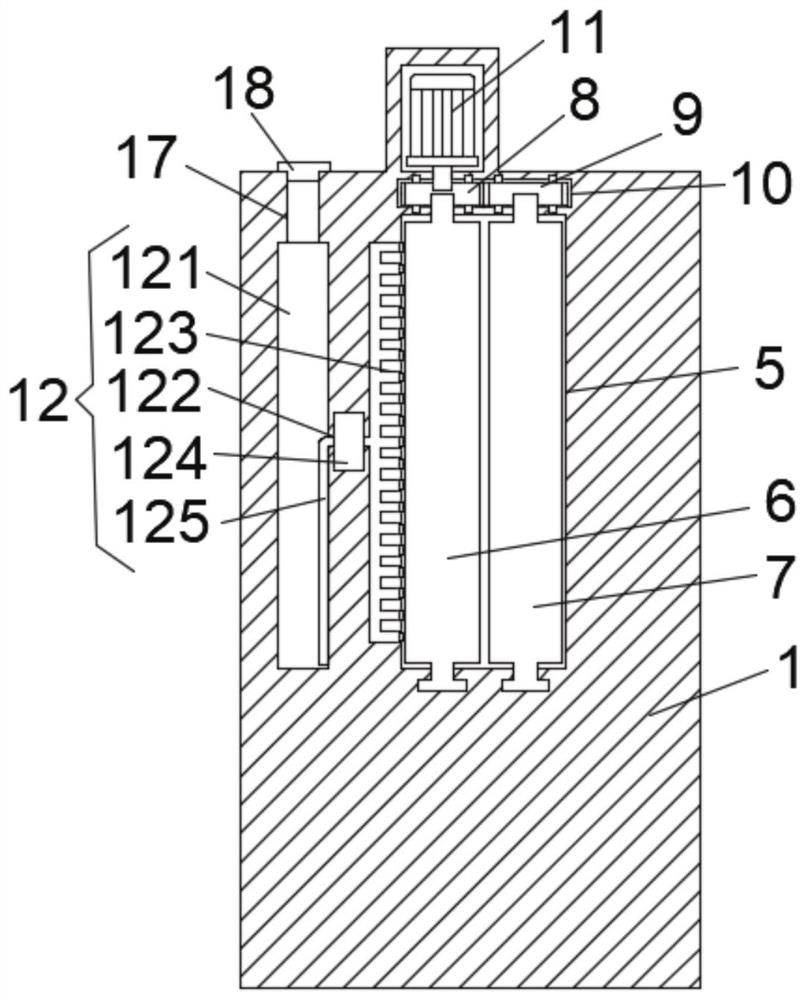

[0022] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: an oil-immersed transformer end insulation automatic bonding machine, including a main body 1, a bonding chamber 2 is opened on the front side wall of the main body 1, and a lower side wall of the bonding chamber 2 is rotatably connected with a rotating Table 3, the rotating table 3 is used to place the iron core of the transformer, the lower side wall of the rotating table 3 is fixedly connected with the first motor 4, the rotating table 3 is driven by the first motor 4 to rotate, and the first motor 4 is fixedly installed on the main body 1 The inner cavity of the bonding chamber 2 is provided with an insulating paper input groove 5 on the right side wall of the adhesive chamber 2, and the first roller 6 and the second roller 7 are rotatably connected in the insulating paper input groove 5 The top of 7 is fixedly installed with first gear 8 and seco...

Embodiment 2

[0028] see Figure 6 , Figure 7 and Figure 8 The difference between the technical solution provided by the present invention and the technical solution in Embodiment 1 is that a rotating ring 19 is rotatably connected in the glue tank 121, and the center of the rotating ring 19 is fixedly connected with a fixed shaft 21 through a connecting shaft 20. , the side wall of the fixed shaft 21 is fixedly equipped with a stirring rod 22, and a linkage device 23 is fixedly installed between the side wall of the rotating ring 19 and the side wall of the first gear 8. After the first gear 8 rotates, the linkage device 23 drives The rotating ring 19 rotates, so that the stirring rod 22 stirs the glue in the glue tank 121 to ensure that the glue has better fluidity.

[0029] Linkage device 23 comprises transmission shaft 231, and transmission shaft 231 is fixedly installed in the inner cavity of main body 1, and the bottom end of transmission shaft 231 is meshed with rotating ring 19,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com