Spot color ink amount and color determination method capable of minimizing color difference

A determination method and color difference technology, which is applied in the field of spot color ink volume and color determination, can solve the problem of low color matching efficiency, meet the color matching requirements and improve the color matching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

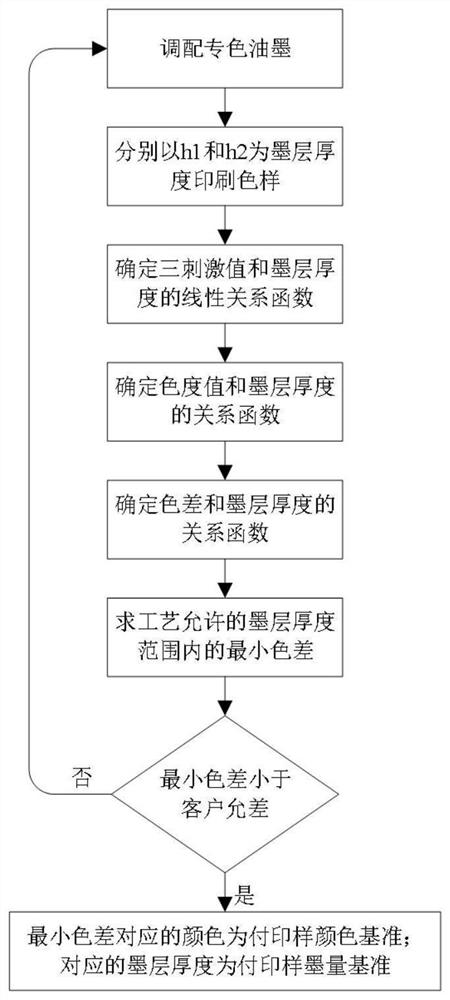

[0034] Below in conjunction with accompanying drawing, the present invention will be further explained;

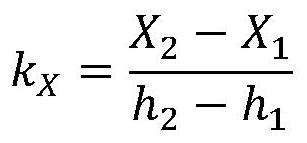

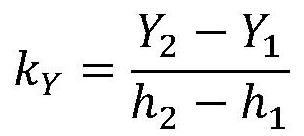

[0035] When deploying spot color inks for offset printing, in order to ensure that the printed ink can meet the target color requirements after being put on the machine, it is necessary to use a color development instrument to print the color sample. The commonly used offset printing ink color development instrument in this field is the IGT C1 offset printing suitability produced by the Netherlands IGT company. The domestically produced ink printing suitability tester and so on. Since the area of the ink coating area on the color development instrument is fixed, the color development instrument controls the ink layer thickness of the color sample by controlling the volume of the ink injection. When printing with a colorimeter, the thickness of the ink layer on the printing disc can be calculated based on the ink filling volume of the ink injector, divided by the sum of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com