Tipping bucket type rain gauge

A tipping bucket rain gauge and rain sensing technology, which is applied in rainfall/precipitation gauges, measuring devices, meteorology, etc., can solve the problems that the tipping bucket cannot be turned over correctly and in time, the rainfall measurement is inaccurate, and the reed switch is damaged. Achieve the effect of improving measurement accuracy, meeting precise measurement requirements, and reducing the use of fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, innovative features and functions realized by the present invention easy to understand, the present invention will be further described below.

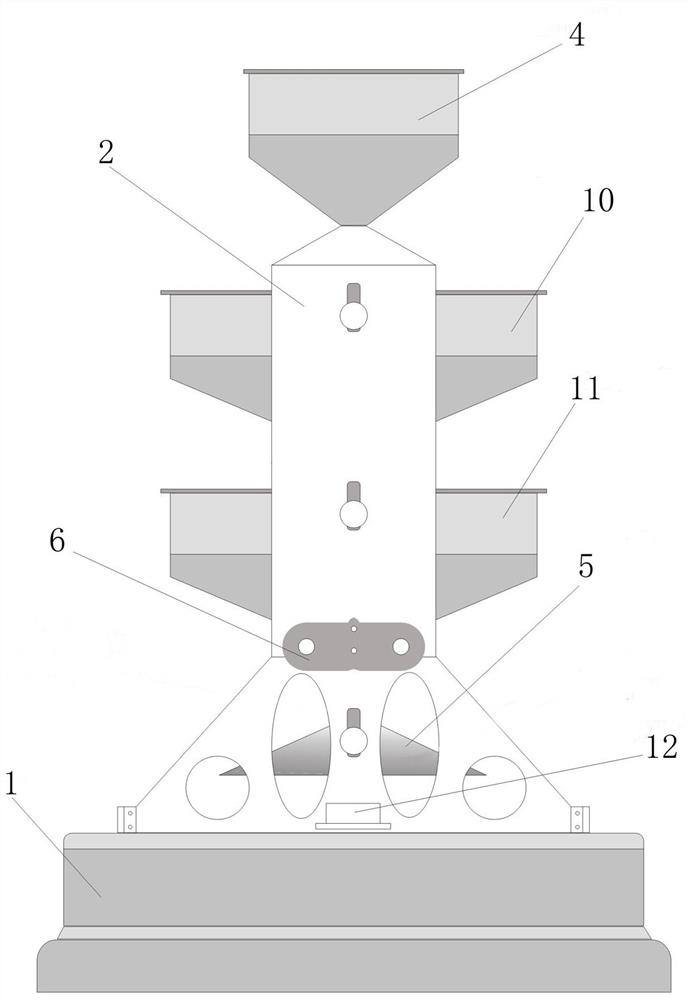

[0017] Such as Figure 1-Figure 5 As shown, the technical solution of the tipping bucket rain gauge of the present invention includes a base 1, a gantry support 2 fixedly formed on the base 1, a support 3 fixed on the top of the gantry support 2, and the bottom passes through the support 3 and is fixed. The rain funnel 4 installed on the support 3, the multiple tipping buckets reversibly installed on the gantry support 2, the measuring tipping bucket reversibly installed on the bottom of the gantry support 2, and the rain sensing mechanism fixedly installed on the gantry support 2 6. An output terminal and a one-point positioning mechanism connected and coordinated with the rainfall sensing mechanism 6. The gantry bracket 2 includes an integrally formed gantry left bracket 2.1 and a gantry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com