A child seat fixing bracket assembly for a vehicle

A technology for fixing brackets and child seats, applied in the field of vehicles, can solve the problems of lack of versatility of fixing brackets, increase vehicle manufacturing costs, poor process operability, etc., and achieve simplified structure types and hook types, simplified manufacturing process, and versatility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

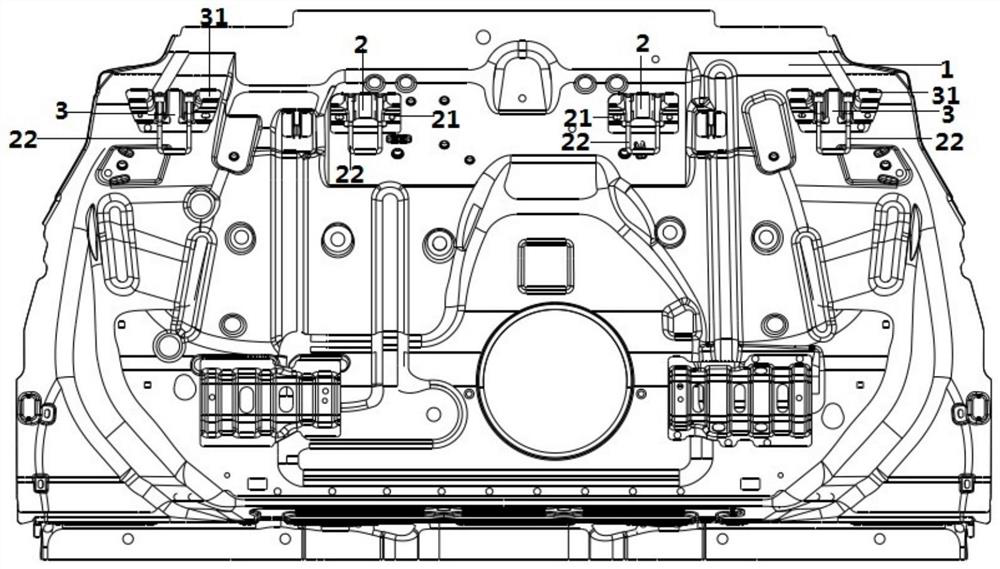

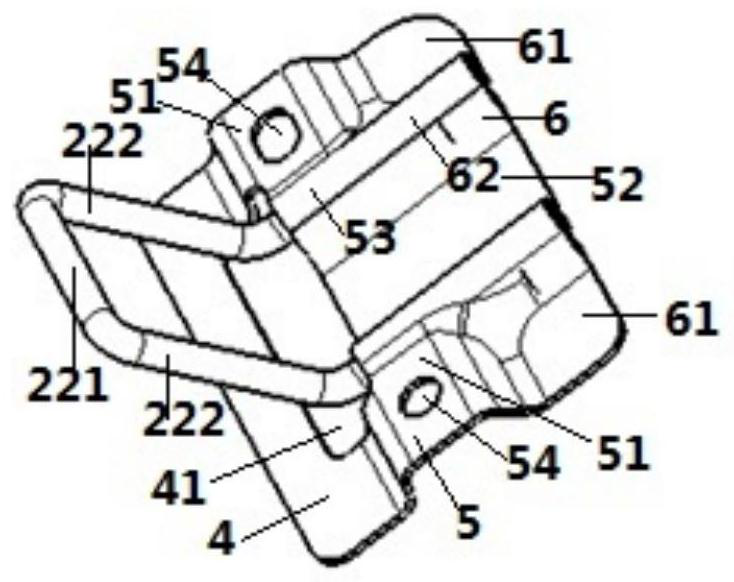

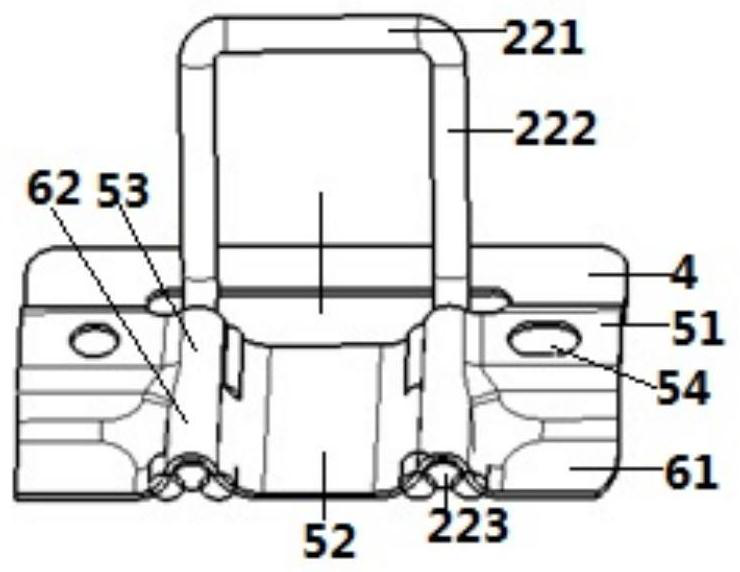

[0038] figure 1 is a schematic diagram of the distribution of the child seat fixing bracket assembly at the mid-bottom plate according to an embodiment of the present invention, figure 2 is a schematic perspective view of a first fixing bracket according to an embodiment of the present invention, image 3 yes figure 2 The three-dimensional schematic diagram of the first fixed bracket in another angle direction, Figure 4 is a schematic perspective view of a second fixing bracket according to an embodiment of the present invention, Figure 5 yes Figure 4 The three-dimensional schematic diagram of the second fixed bracket in another angle direction. see figure 2 and Figure 4 , see also figure 1 , image 3 and Figure 5 , this embodiment takes figure 2 and Figure 4 To explain to the Lord. see figure 1 , the vehicle includes a midsole 1, see figure 2 and Figure 4 , the child seat fixing bracket assembly for vehicles includes at least one first fixing bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com