Lower end hydraulic support for steep slope tunnel and application method

A technology of hydraulic support and end support, which is applied in the direction of mine roof support, earth square drilling, mining equipment, etc. It can solve the problems of dynamic longitudinal unbalance, bite frame, static lateral instability, etc., and achieve simple support structure and easy installation. Easy to place effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

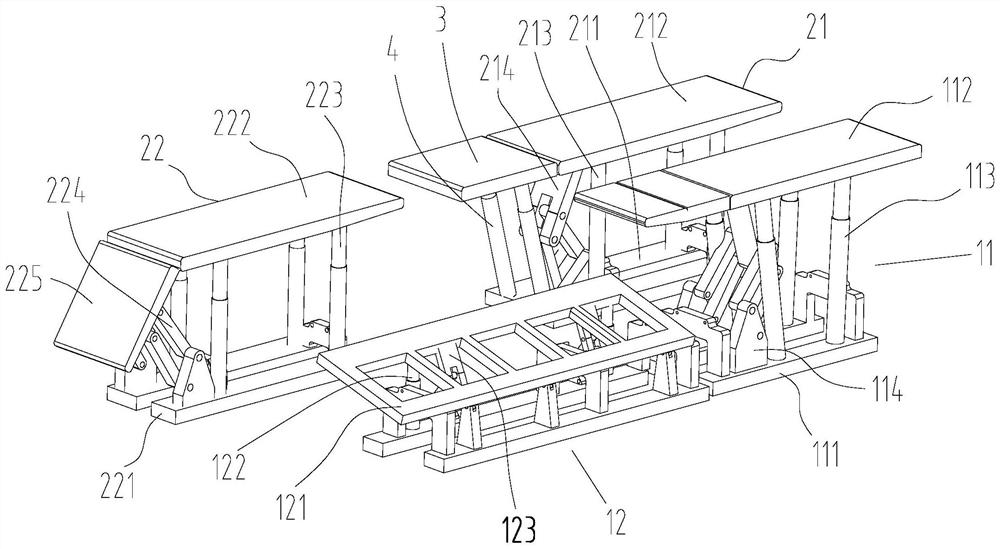

[0025] Embodiment one, such as figure 1 , 2 As shown, the structure of the present invention includes a first support 1 and a second support 2, both of which are located at the exit at the bottom of the steeply inclined roadway.

[0026] The first support 1 includes a terminal support 11 and a sliding runway 12, the terminal support 11 and the sliding runway 12 are arranged in close proximity, and the sliding runway 12 is close to the exit at the bottom of the steeply inclined roadway.

[0027] The end bracket 11 includes a first base 111, a first support beam 112, a first oil cylinder 113 and a first linkage 114, the first support beam 112 is fixed above the first base 111 by the first oil cylinder 113, and the first oil cylinder 113 One end is hinged or fixed to the first base 111, and the other end is hinged to the first support beam 112. The first support beam 112 expands and contracts through the first oil cylinder 113 to realize lifting action. The first linkage mechani...

Embodiment 2

[0036] In the second embodiment, the support slide 121 is hinged to the first base 111 through a support column, that is, one end of the support column is fixed to the first base 111, and the other end is hinged to the support slide. According to different actual working conditions, support columns of different heights are used to increase the The stability of the sliding runway 12 is improved, and the supporting slide plate 121 can flexibly swing at different angles to adapt to sharply inclined roadways at different angles. All the other are the same as embodiment one.

Embodiment 3

[0037] Embodiment 3, the first base 111 is divided into two parts, one part is the base of the end support 11, and the other part is used to fix the sliding track 12, and a telescopic oil cylinder is arranged between the two parts of the base, and the oil cylinder is respectively fixed on the two parts The base realizes the adjustment of the distance between the two parts of the base through the expansion and contraction of the oil cylinder, so that the distance between the end support 11 and the sliding track 12 can be adjusted more flexibly. All the other are the same as embodiment one.

[0038] The first base 111, the second base 211 and the third base 221 can add frame box-type bases, that is, set a frame box-type base on each base, so that pedestrian passages can be added in the bases, and isolation nets and escalators are used. And other devices are fixed on the base frame by welding to allow personnel to enter and exit, while preventing gravel or sundries from falling i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com