A non-peripheral opening flow-limiting booster check valve

A one-way valve and flow-limiting technology, which is applied in the direction of machines/engines, rocket engine devices, jet propulsion devices, etc., can solve problems such as fluttering and unstable operation of the check valve spool, engine structure damage, etc., to avoid propellant Or gas backflow, increase the opening maintenance force, and improve the effect of working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

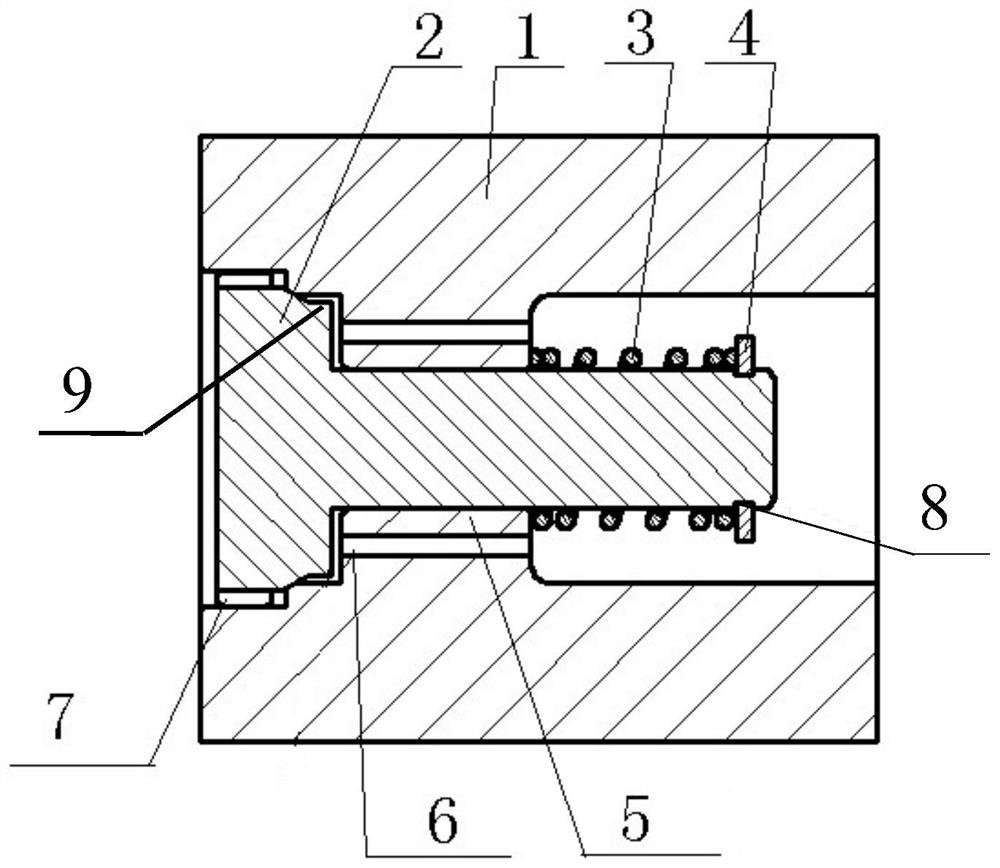

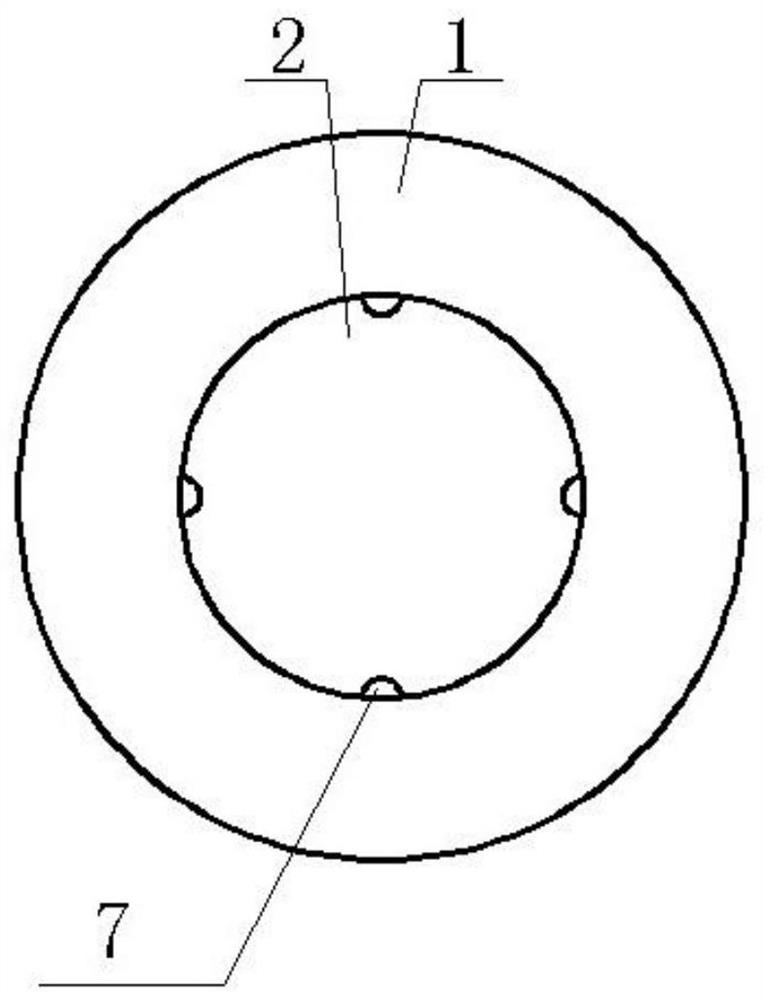

[0025] Such as figure 1 and figure 2 As shown, a non-circumferential opening flow-limiting booster check valve in this embodiment includes a valve body 1, a valve core 2, a spring 3 and a retaining ring 4;

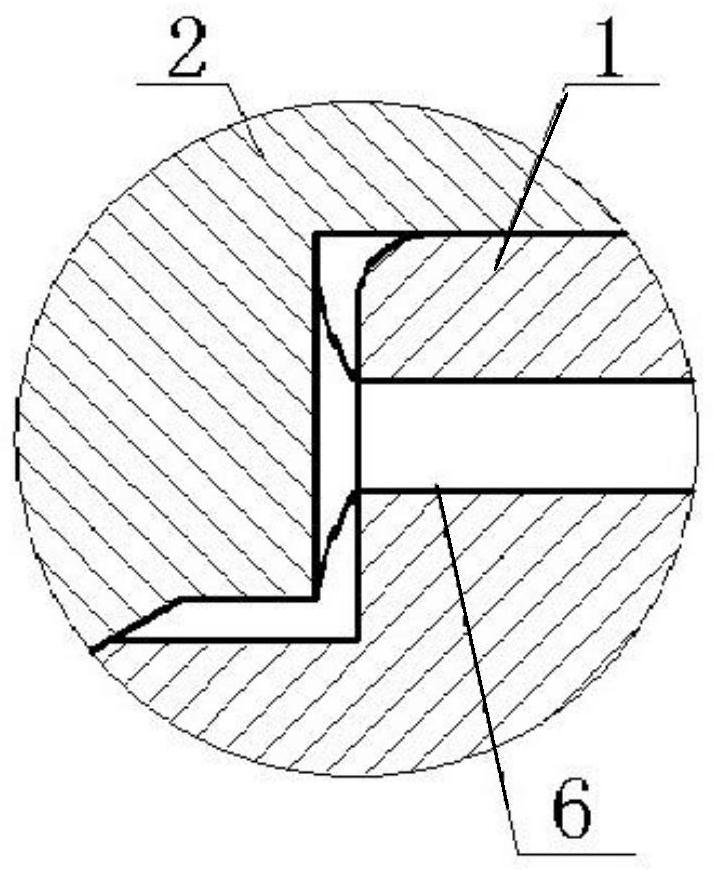

[0026] The inner wall of the valve body 1 is coaxially provided with an annular protrusion 5, and the annular protrusion 5 is provided with two flow-limiting holes 6 along the axial direction, and the two flow-limiting holes 6 are symmetrically arranged on the annular protrusion 5 ;

[0027] The annular protrusion 5 divides the valve body 1 into an oil inlet chamber and an oil outlet chamber, the oil outlet chamber is set as a two-stage stepped hole, and the joint between the two-stage stepped holes is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com