Liquid-solid separation device for kitchen waste

A kitchen waste and solid separation technology, which is applied in trash cans, garbage collection, cleaning hollow objects, etc., can solve the problems of affecting the subsequent use of the device, low working efficiency of the device, and physical hazards of medical staff, etc., to achieve convenient compression and lifting The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

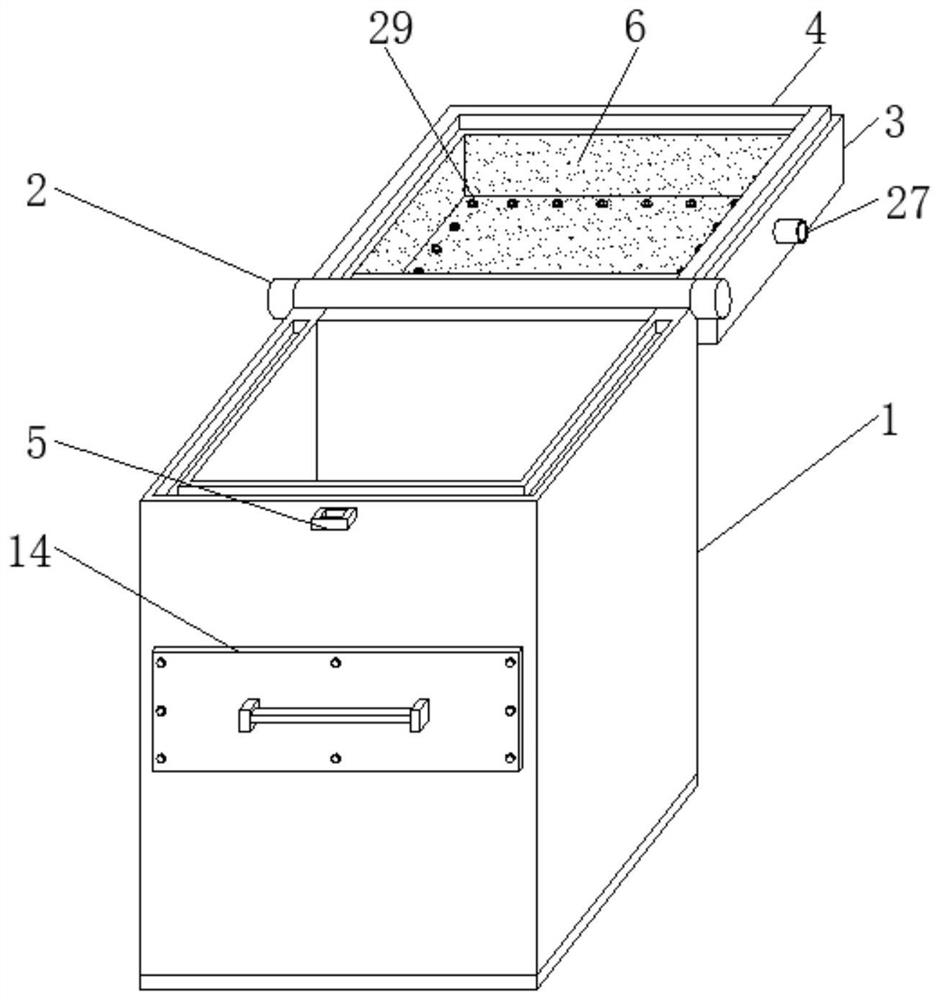

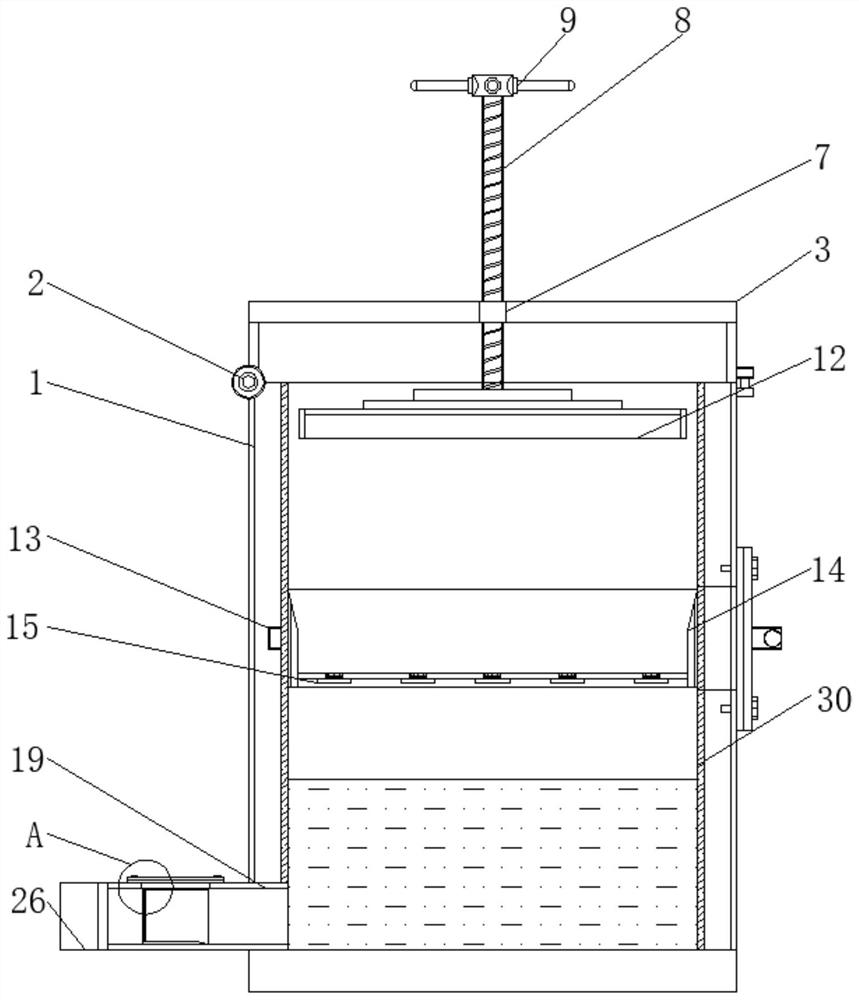

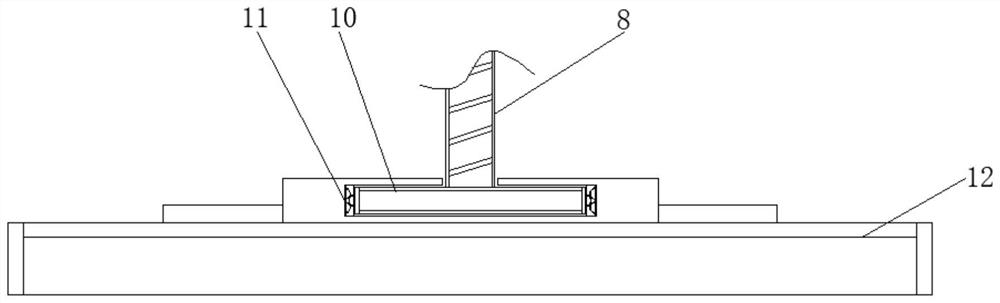

[0039] see figure 1 , a liquid-solid separation device for kitchen waste, comprising a separation main body 1, a positioning shaft 2 is provided on the upper side of the rear end of the separation main body 1, and a sealing cover plate 3 is provided on the upper end of the positioning shaft 2, and the sealing cover The inner side of the plate 3 is provided with a positioning bump 4, the separation body 1 forms a rotating structure through the positioning shaft 2 and the sealing cover plate 3, and the front surface of the separation body 1 is provided with a positioning slot 5, and the separation body 1 passes through the positioning card. A sealing structure is formed between the groove 5 and the positioning protrusion 4 and the sealing cover plate 3. The inclination angle of the sealing cover plate 3 can be flexibly changed through the positioning shaft 2 provided, and the positioning protrusion 4 and the positioning card groove 5 are matched with each other. , the sealing co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com