Centrifugal separator

A centrifugal separator and separator technology, which can be used in centrifuges, centrifuges with rotating drums, dairy products, etc., and can solve problems such as reduced efficiency and reduced degreasing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the invention will now be described more fully hereinafter with reference to the accompanying drawings, in which some, but not all embodiments of the invention are shown. This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein.

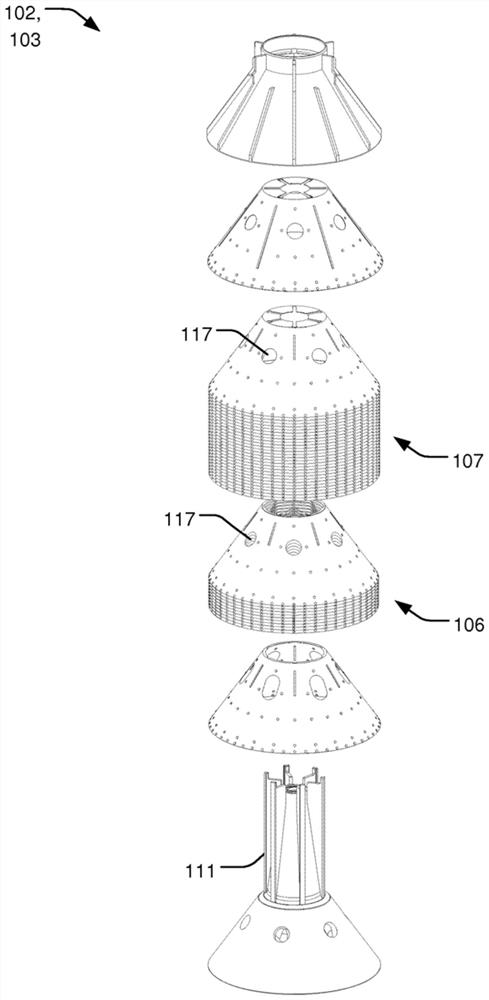

[0014] figure 1 is a schematic diagram of a separator 100 for separating milk (RM) into a cream phase (CR) and a skim milk phase (SM). The separator 100 comprises a centrifuge bowl 101 and a disk stack 102 of conical disks 103 arranged within the centrifuge bowl 101 . Milk (RM), commonly referred to as raw milk, enters the centrifuge bowl 101 via inlet 113 and is subsequently separated at the top of the centrifuge bowl 101 into a skim milk phase (SM) and a cream phase (CR). That is, milk (RM) flows from inlet 113 into distribution opening 117 in disc stack 102, and cream phase (CR) is centrifuged towards and flows from center portion 118 or disc stack 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com