Mechanical and electrical product detection table

A technology of electromechanical products and testing tables, which is applied in the field of testing tables, can solve the problems of inconvenient handling and high testing tables, and achieve the effect of lifting labor and preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

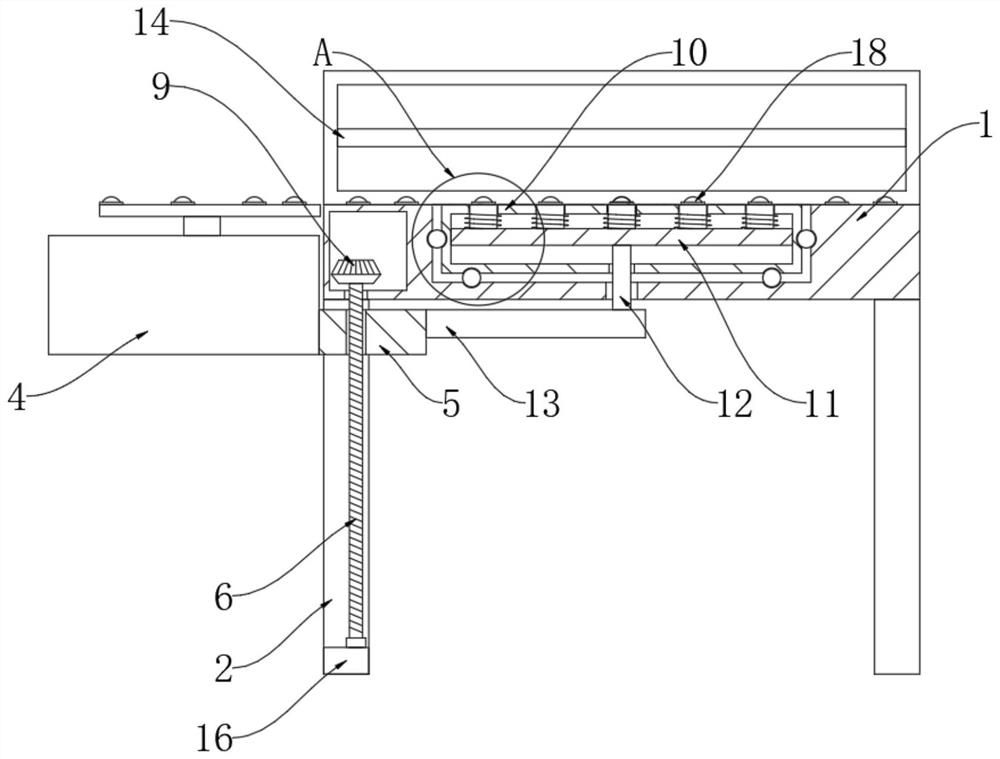

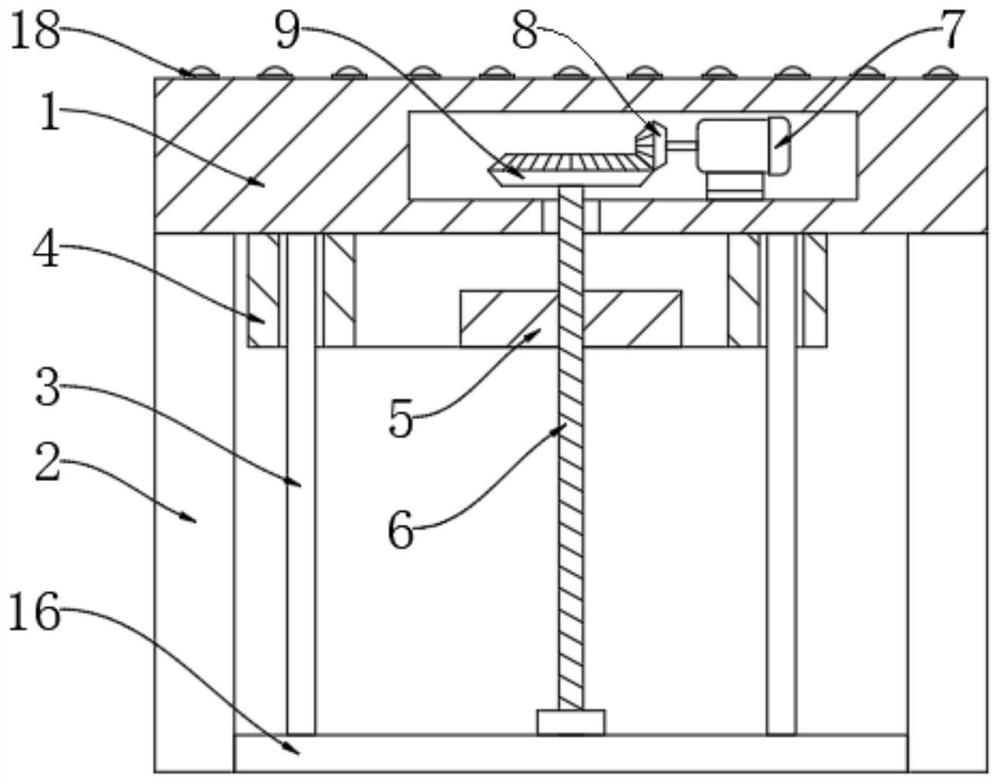

[0025] refer to Figure 1-4 , a testing platform for electromechanical products, including a workbench 1, support legs 2 are fixedly connected to the four corners of the lower surface of the workbench 1, a sliding column 3 is fixedly connected to the left edge of the lower surface of the workbench 1, and the sliding column 3 The surface is slidingly connected with a lifting plate 4, the side of the lifting plate 4 is fixedly connected with a connecting block 5, the upper surface of the connecting block 5 is provided with a threaded hole, and the inner wall of the threaded hole is threaded with a screw rod 6, and the two supporting legs 2 on the left The opposite surface is fixedly connected with a reinforced square rod 16, the bottom end of the sliding column 3 is fixedly connected with the upper surface of the reinforced square rod 16, and the bottom end of the screw rod 6 is rotatably connected with the upper surface of the reinforced square rod 16 through a bearing.

[0026...

Embodiment 2

[0033] refer to Figure 4-6, the inside of the lifting plate 4 is provided with an oil chamber 21, and the inside of the oil chamber 21 is provided with hydraulic oil, and the center of the upper surface of the lifting plate 4 is provided with a circular stepped groove extending to the inner top wall of the oil chamber 21, And the inner wall of the circular step groove is slidingly connected with a pressure column 22, the top of the pressure column 22 is fixedly connected with a pressure plate 23, the upper surface of the pressure plate 23 is provided with the same support ball 18 on the upper surface of the workbench 1, and the upper surface of the lifting plate 4 A U-shaped groove is provided, and the inner wall of the U-shaped groove is slidably connected with a U-shaped block 24, and the inner bottom wall of the U-shaped groove is provided with a circular hole extending to the inner wall of the oil chamber 21, and the inner wall of the circular hole is slidably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com