Flaw detection device and application thereof

A flaw detection device and probe technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems that the authenticity of the detection cannot be fully reflected, it is difficult to find the defects of the tenon teeth of the turbine disc, and the detection period is long. Achieve the effect of high promotion and application value, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

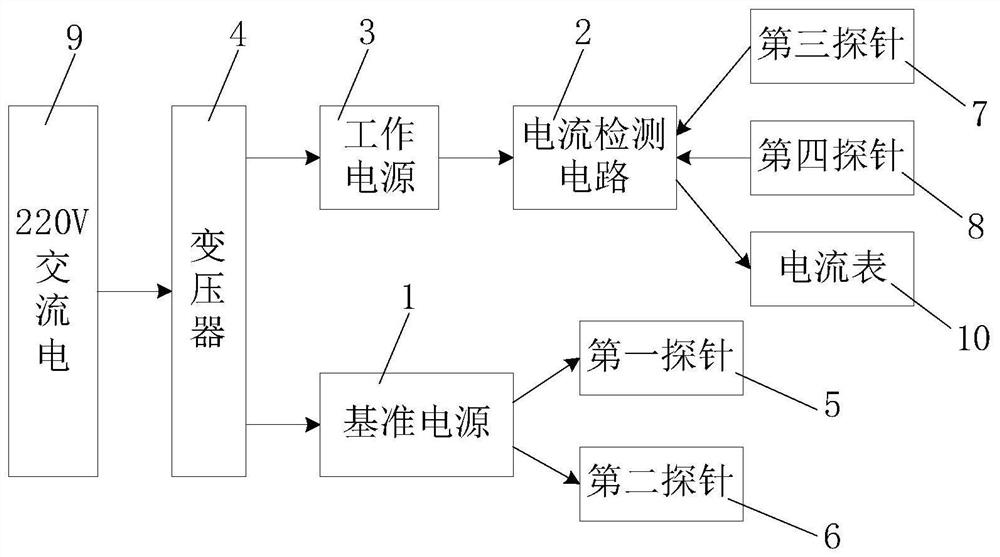

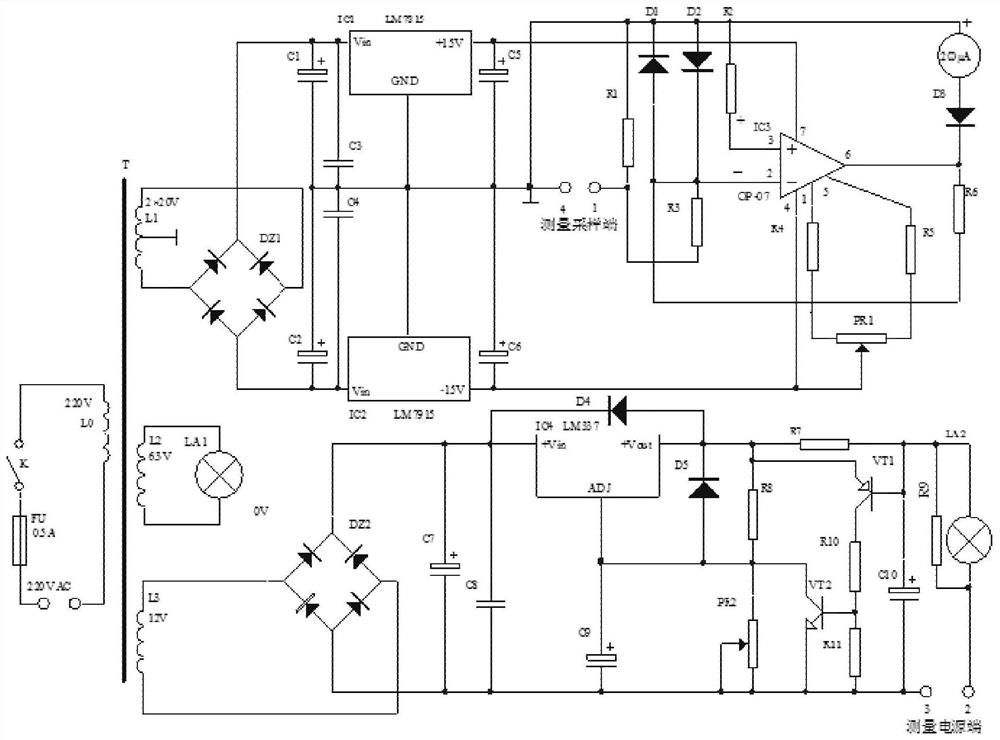

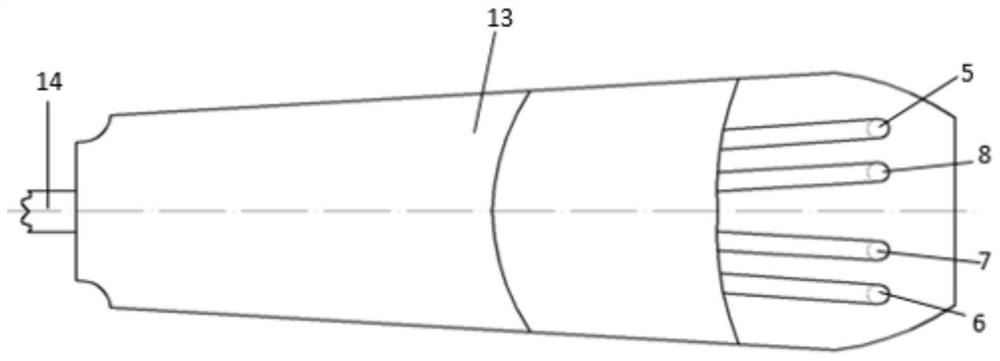

[0027] Such as figure 1 As shown, the flaw detection device of the present invention includes a reference power supply 1 for loading a reference voltage to the tenon teeth of the turbine disc and a current (constant voltage micro-current change) detection circuit 2 for detecting current changes on the tenon teeth of the turbine disc, and uses For the working power supply 3 that provides power for the current detection circuit 2 and the transformer 4 for connecting to the external 220V AC power supply 9, the reference power supply 1 and the working power supply 3 are respectively connected to the L3 and L1 secondary windings of the transformer 4; the positive pole of the reference power supply 1 The output terminal is connected with the first probe 5, the negative output terminal of the reference power supply 1 is connected with the second probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com