Raw material drying device for feed production and drying method thereof

A drying device and raw material technology, applied in drying, drying machine, heating device and other directions, can solve the problems of large labor force, time-consuming and labor-intensive, unfavorable for mass production of feed, etc., and achieve the effect of improving drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

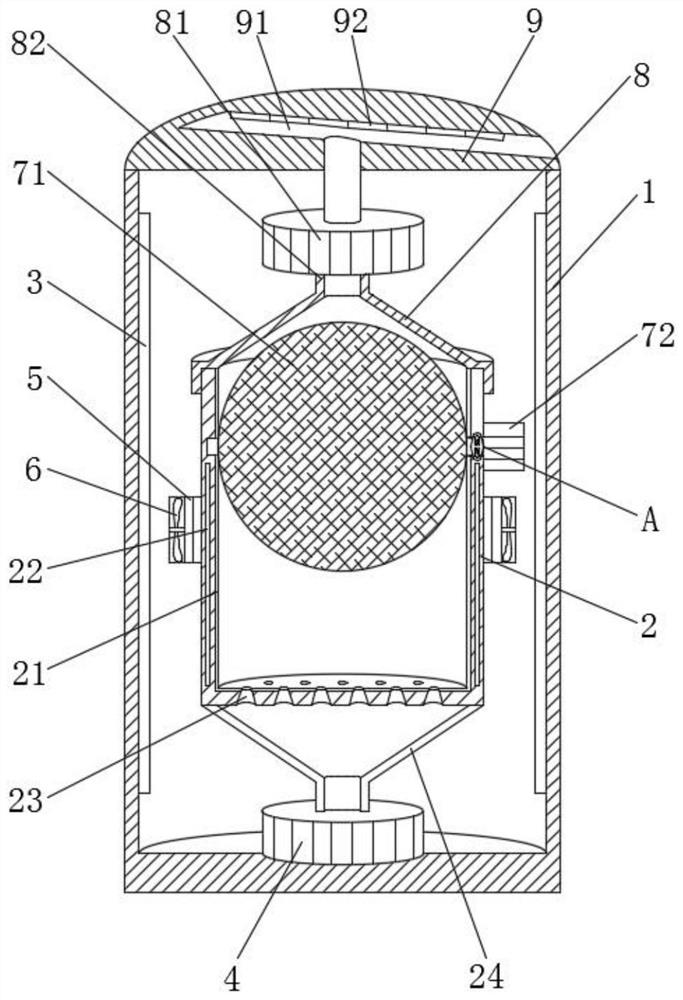

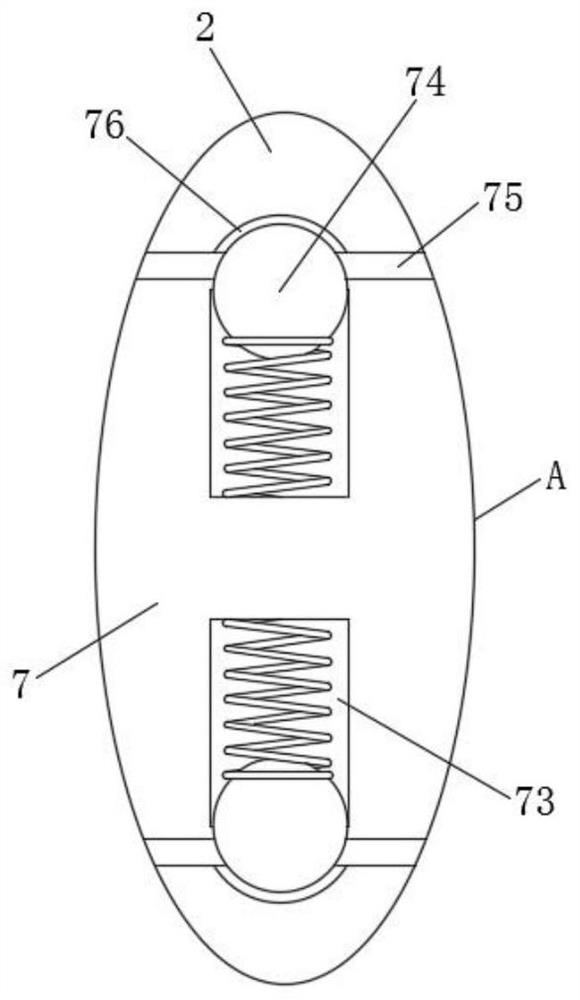

[0023] see Figure 1-2 , this embodiment provides a raw material drying device for feed production, including a material box 1, a material container 2 is installed inside the material box 1, an electric heating wire 3 is installed on the inner wall of the material box 1, and the bottom side of the material container 2 is installed. An air pump 4 is installed on the outer wall of the container, and the raw material to be dried is placed in the interior of the material carrier 2, and then the power supply of the heating wire 3 and the air pump 4 is closed, and the heating wire 3 heats the air inside the material box 1, so that Heat is exchanged between the raw material and the air inside the material box 1 , so that the moisture inside the raw material evaporates quickly.

[0024] An insulating layer 21 is provided on the inner wall of the carrier tube 2 , a pipeline 22 is opened inside the side wall of the carrier tube 2 , the inside of the pipeline 22 is filled with a cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com