Hydrolytic acidification reaction tank for sewage treatment

A technology for hydrolytic acidification and sewage treatment, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, biological treatment devices, etc. It can solve the problems of affecting the progress of hydrolytic acidification reaction, energy absorption buffer, and the loss of diversion in the diversion table. , to avoid enlarged extrusion overlap and increase the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

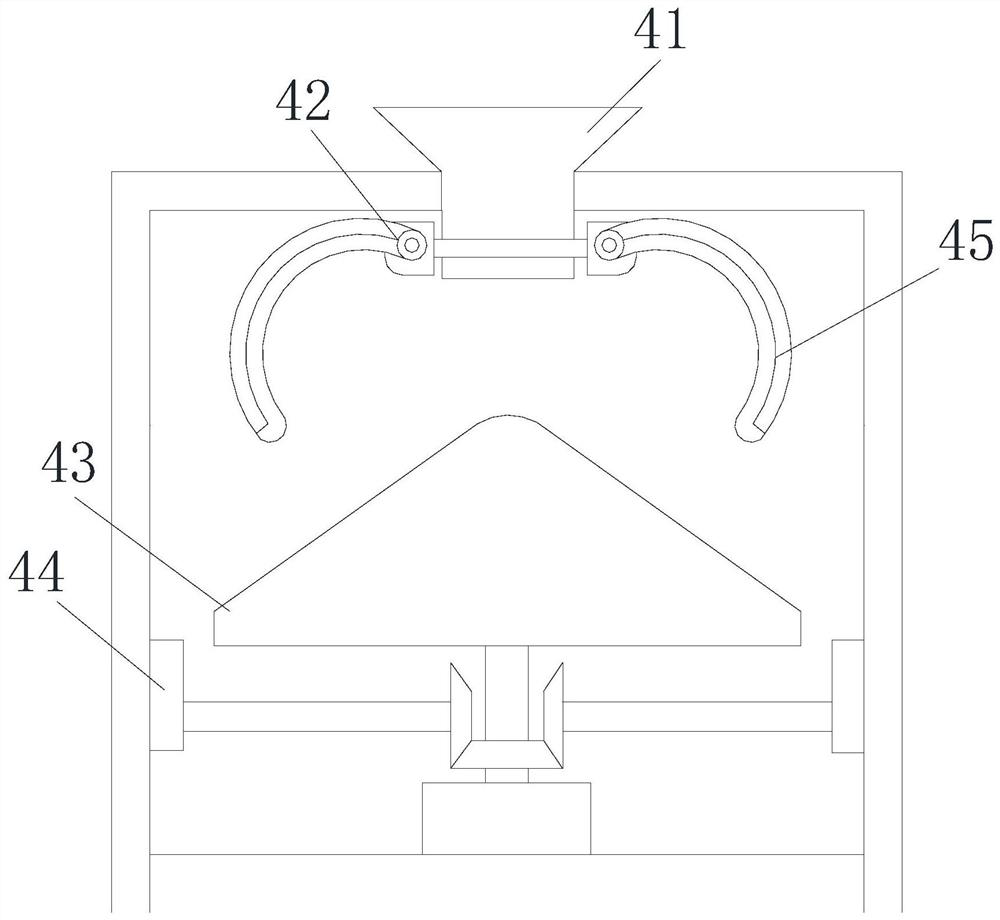

[0030] Such as Figure 1-Figure 4 As shown, the present invention provides a hydrolysis acidification reaction tank for sewage treatment. The middle part of the cover 2 communicates with the inside of the reaction device 4. The outside of the reaction device 4 is covered with a support frame 3, and the bottom is fixedly connected with a centralized acidification place 5. The reaction device 4 includes a feed port 41 and a cyclocross device 42. , shunt structure 43, top support 44, stirring hook angle 45, the feed inlet 41 and the feed pipe 1 are connected to each other, and the bottom thereof is movably matched with the stirring hook angle 45 through the ring crosser 42, and the stirring The hook angle 45 interferes with the gap at the top of the diversion structure 43, and the bottom is welded to the top support member 44. The diversion structure 43 includes a conversion device 431, a fixed rod 432, a fitting block 433, a sleeve 434, a support device 435, and a guide Rod 436...

Embodiment 2

[0032] Such as Figure 5-Figure 7 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The support device 435 includes an anti-collision device 351, a gathering bolt 352, a limit part 353, a pair of bars 354, a sleeve 355, a buckle Closing ring 356, the anti-collision device 351 is a hemispherical structure, which is arranged on both sides of the bottom of the anti-accumulation long road 312 and the anti-accumulation short road 315, and is welded to the pair of bars 354. Embedded in the inner circumferential groove of the sleeve 355, the fastening ring 356 is movably engaged in the middle of the gathering bolt 352, and the limiting part 353 is fixedly connected between the two sleeves 355, and the gathering bolt 352 and the fastening The ring 356 is inserted into the inner circumferential groove of the sleeve 355 through the limiting part 353, and a triangular structure is formed between the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com