Tower crane remote real-time operation system

A real-time operating system and remote control technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as high-efficiency transfer, visual fatigue, precise positioning of construction raw materials, etc., to save labor, avoid fatigue driving, The effect of eliminating the risk of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

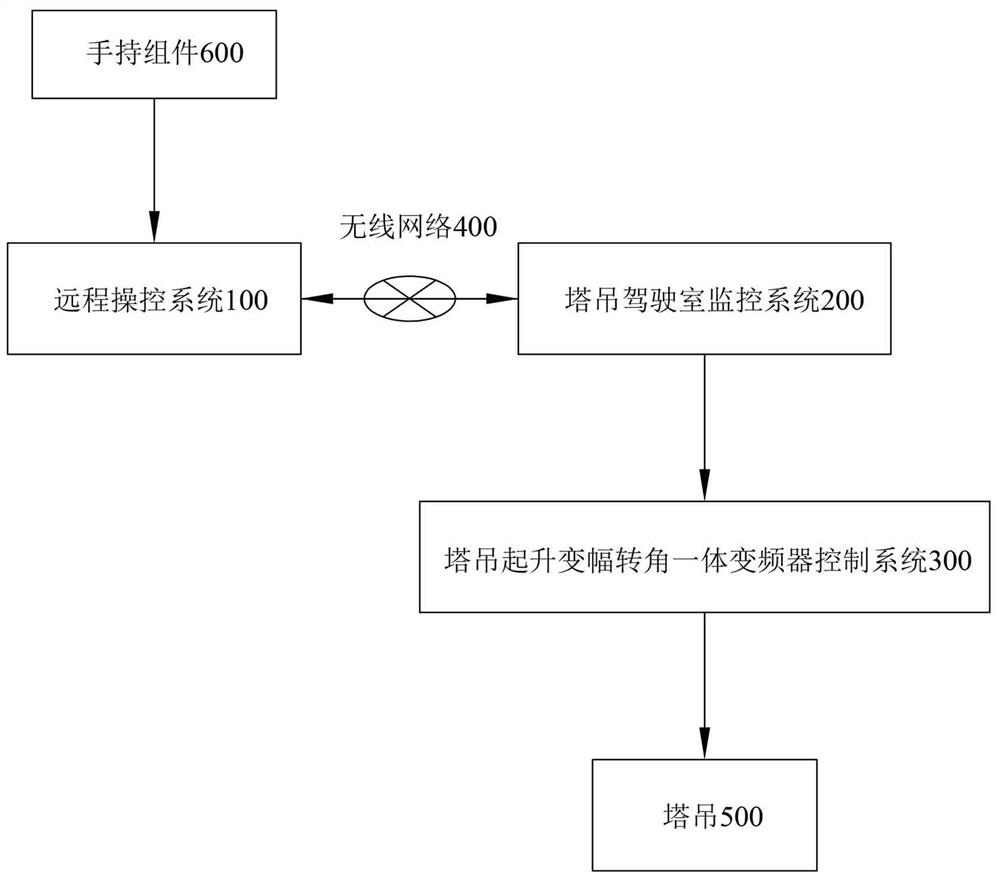

[0021] A remote real-time operating system for tower cranes, such as figure 1 As shown, it includes a remote control system 100, a tower crane cab monitoring system 200, and a tower crane hoisting and luffing angle integrated inverter control system 300. The remote control system 100 and the tower crane cab monitoring system 200 communicate bidirectionally through a wireless network 400. The tower crane cab The monitoring system 200 is connected to the control system 300 of the integrated inverter control system for tower crane lifting, luffing, and turning angle; the control system 300 for the integrated inverter controlling system for tower crane lifting, luffing, and turning angle is connected to the tower crane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com