Shaping and edge cutting equipment of textile machinery

A technology of textile machinery and trimming, which is applied in the cutting of textile materials, textile and papermaking, fabric surface trimming, etc., can solve the problems of inability to adjust the trimming spacing, and the waste is not easy to be recycled, so as to reduce the number of placements, increase the applicability, The effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

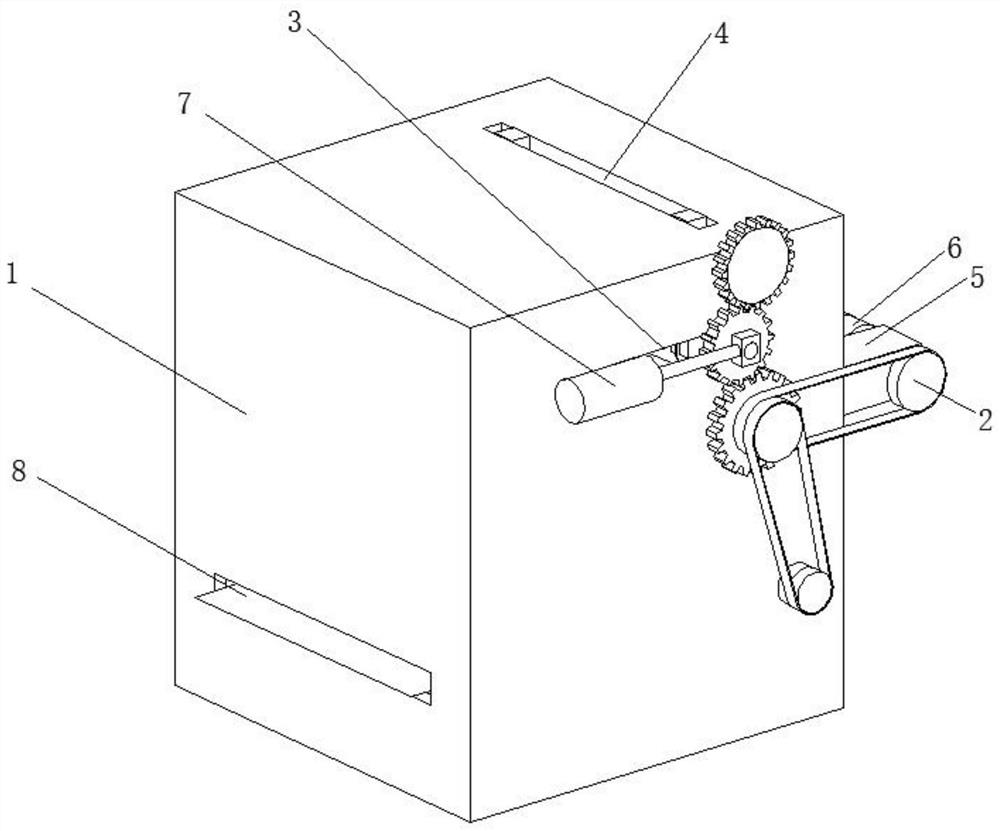

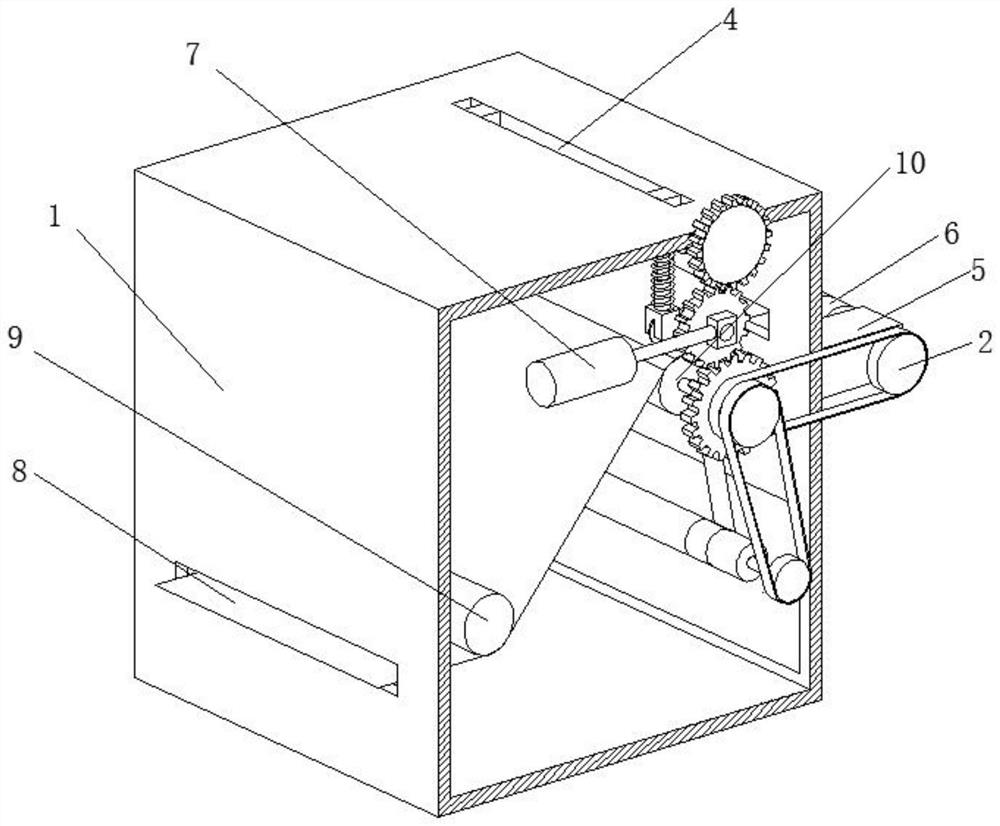

[0030] A stereotyped trimming device for textile machinery, such as Figure 1-Figure 6 As shown, it includes a box body 1, a transmission mechanism 2 is provided on the right side of the box body 1, a chute 3 is opened on the right side of the box body 1, a slide rail 4 is opened on the top of the box body 1, and the rear part of the box body 1 is welded There is a support block 5, two support blocks 5 are arranged, and a winding drum 6 is rotatably connected between the two support blocks 5, and a trimming mechanism 7 is arranged on the right side of the box body 1, and the trimming mechanism 7 is located in the transmission mechanism 2 Above, the surface of the winding drum 6 is fixedly connected with a cloth 8, the inner wall of the box body 1 is provided with a shaping mechanism 9, and the inner wall of the box body 1 is rotatably connected with a support roller 10.

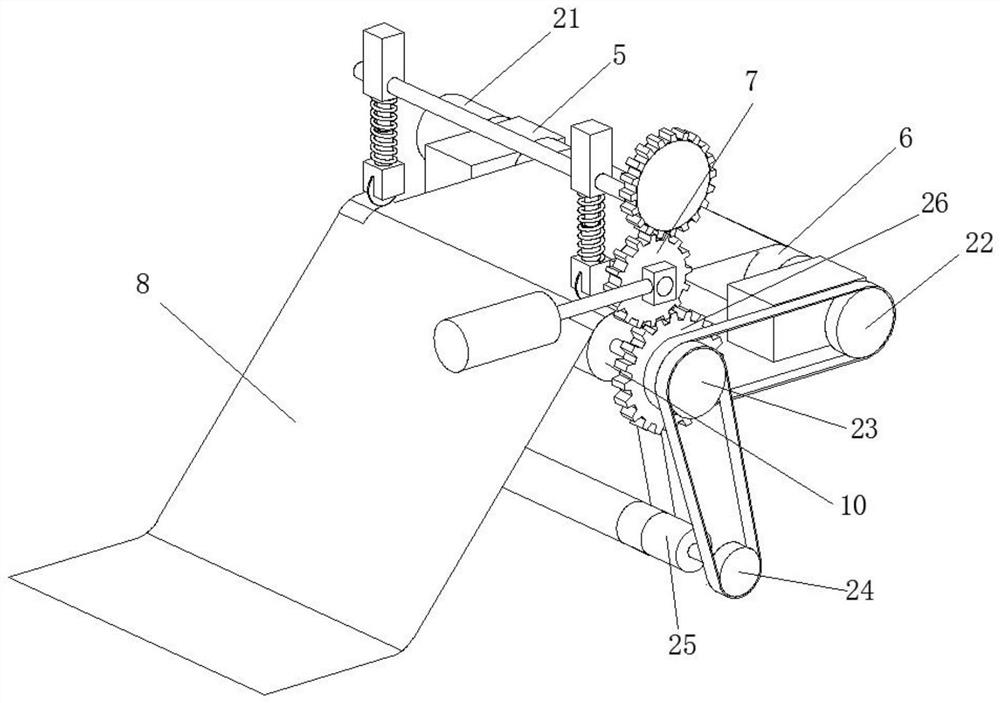

[0031] The transmission mechanism 2 comprises a motor 21, the output end of the motor 21 is clamped and fi...

Embodiment 2

[0039] Such as Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the surface of No. 3 gear 751 and the surface of No. 2 gear 73 mesh with each other, and the axis of No. 2 pinion 753 and the axis of No. 3 gear 751 Welding is fixed, and the surface of slide plate 755 is slidingly connected with the inwall of slide rail 4, and the surface of blade 758 contacts with cloth 8, and the two ends of back-moving spring 757 contact with the bottom of slide plate 755 and the upper surface of blade 758 respectively, and back-moving spring 757 The blade 758 can be tightly pressed against the cloth 8 for cutting, thereby preventing the blade 758 from breaking due to the change of the thickness of the cloth 8, and then being applicable to cloth 8 of different thicknesses, greatly increasing the applicability of the device.

[0040] It is worth noting that the sizing mechanism 9 includes a sizing cylinder 91, the inner wall of the sizing cylinder 91 is welded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com