Efficient cooling type carriage for logistics transportation

An efficient and logistics technology, applied in transportation and packaging, vehicle components, superstructure of trucks, etc., can solve the problems of poor air circulation, easy to generate agglomeration, hidden dangers, etc., and achieve the effect of avoiding spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

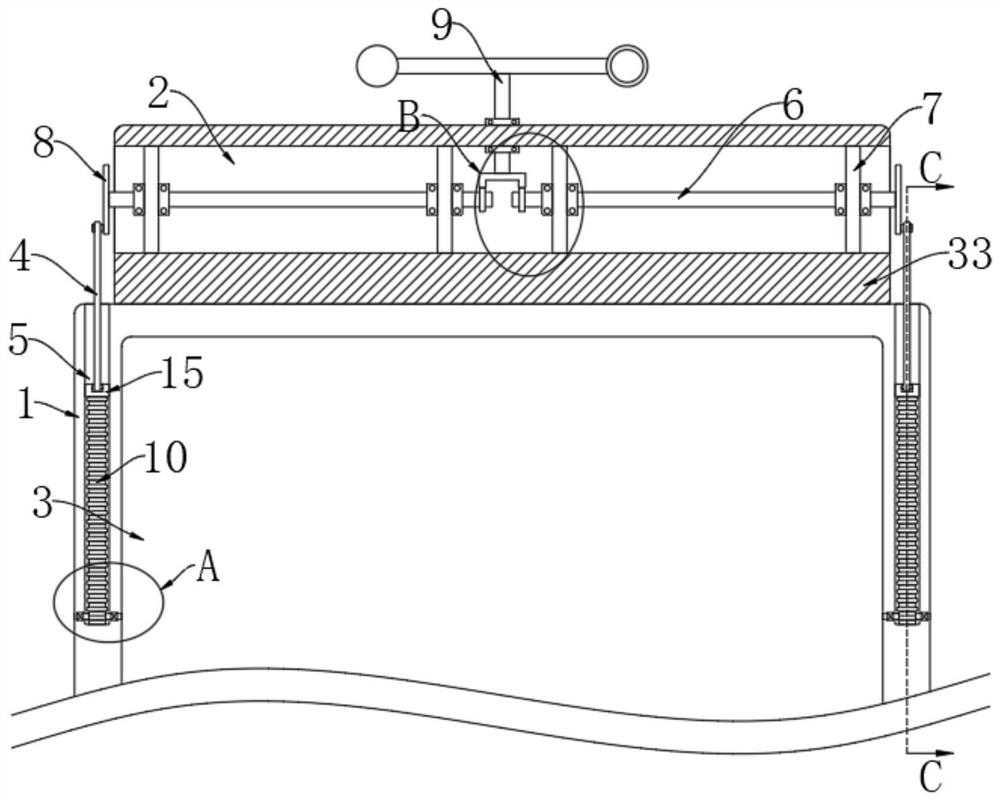

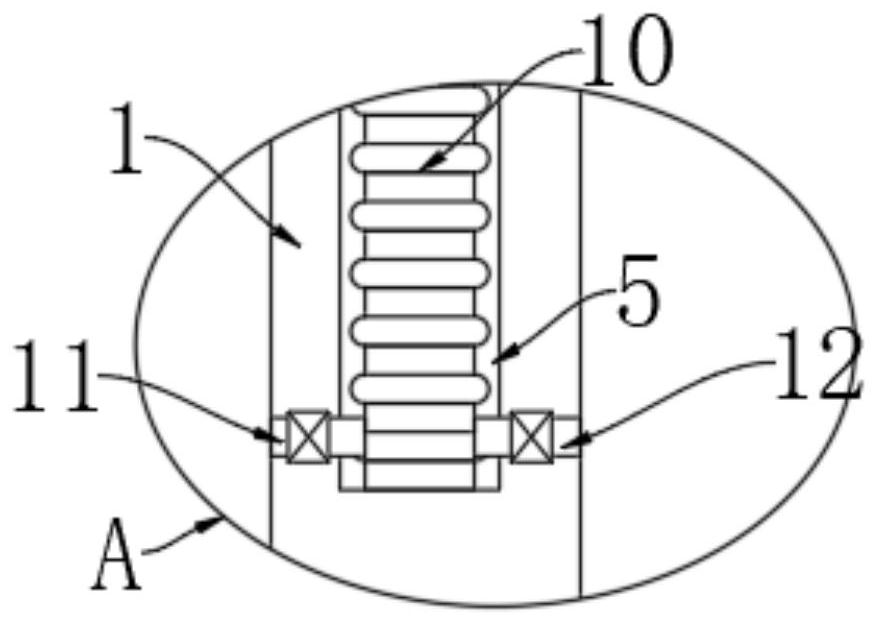

[0025] refer to Figure 1-4 , a high-efficiency cooling compartment for logistics transportation, including a compartment body 1 and an installation bar 33, the installation bar 33 is fixedly connected to the upper end of the compartment body 1, a storage room 3 is provided in the compartment body 1, and a through-hole is installed on the installation bar 33. slot 2;

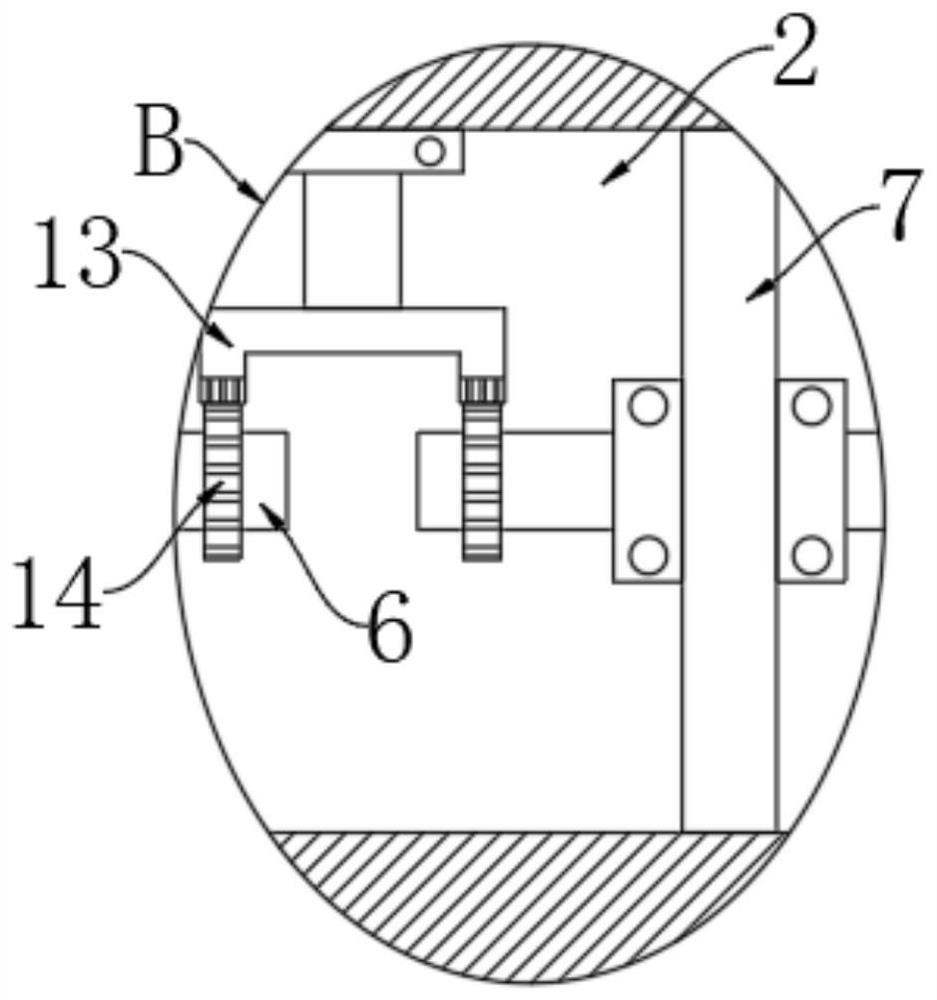

[0026] The trigger module, the trigger module includes the wind cup 9 installed on the upper end of the installation bar 33, the rotating shaft of the wind cup 9 extends into the through groove 2 and is fixedly connected with the crown gear 13;

[0027] The transmission module, the transmission module includes four mounting plates 7 vertically arranged in the through groove 2, the upper and lower ends of each mounting plate 7 are fixedly connected with the inner wall of the through groove 2, and between every two matching mounting plates 7 Both are rotatably connected with a rotating rod 6, and the opposite end...

Embodiment 2

[0033] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that the middle parts of the two rotating rods 6 are provided with a threaded layer, and the threaded layer is a threaded layer similar to a reciprocating screw rod, so that the unidirectional rotation of the rotating rod 6 can drive the first The left and right movement of the magnetic block 17, the threaded layer parts of the two rotating rods 6 are all screwed with the first magnetic block 17, and the lower end of each first magnetic block 17 is all slidably connected with the inner bottom of the through groove 2, and the inner bottom of the mounting bar 33 Two transverse cavities 19 are symmetrically provided, and second magnetic blocks 18 for sliding left and right are arranged in the two transverse cavities 19, and the two second magnetic blocks 18 are all connected to the adjacent surfaces of the corresponding first magnetic blocks 17. Opposites attract each other, the two sides of the ...

Embodiment 3

[0036] refer to Figure 6-7 The difference between this embodiment and Embodiment 2 is that a trigger chamber 23 is provided in the box body 1, and two first pistons 25 sliding left and right are arranged in the trigger chamber 23, and the trigger chamber 23 is located between the two first pistons 25. The space between is filled with carbon disulfide solution, the second air bag 24 is arranged between the two first pistons 25, and the trigger chamber 23 is located at the opposite side space of the two first pistons 25, and the connection port 31 communicating with the storage chamber 3 is provided. , the upper end of the car body 1 is symmetrically provided with two vertical grooves 26, and the two vertical grooves 26 are respectively located on both sides of the trigger chamber 23, and the second piston 27 for sliding up and down is arranged in the two vertical grooves 26, and the two vertical grooves 26 The inside of the groove 26 is provided with a wedge-shaped block 28 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com