Integrated coaxial electric drive axle system

A coaxial, electric drive technology, applied in the direction of electric power devices, power devices, control devices, etc., can solve the problem of low power density of electric drive systems, large volume of inverters and gearboxes, excessive pressure on drive motors, etc. Problems, to achieve the effect of convenient vehicle application layout, good heat dissipation performance, safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

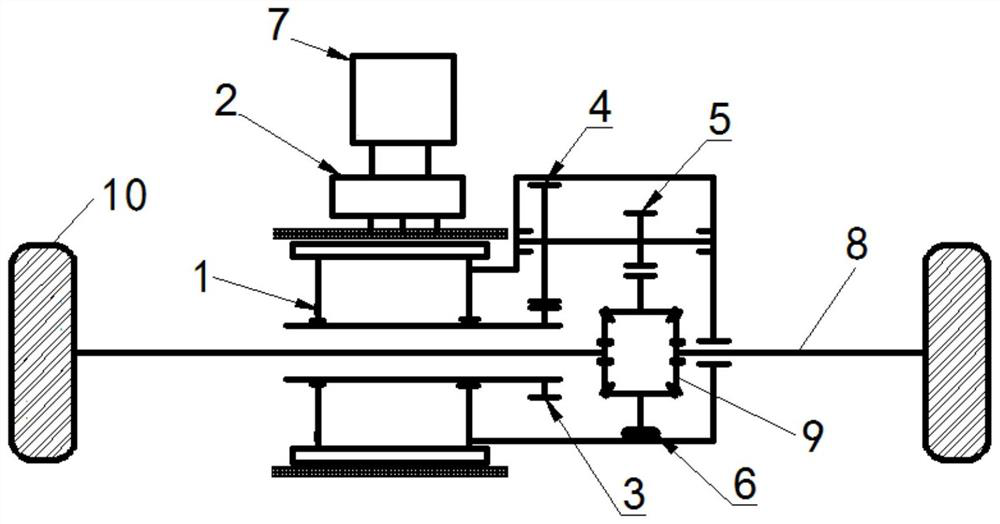

[0024] Such as figure 1 As shown, the present application proposes an integrated coaxial electric drive axle system, including a power battery 7, an inverter 2, a driving motor 1, a coaxial reducer and a differential that are connected in sequence. The inverter 2 is fixed on the driving motor 1 and shares a cooling system and a casing with the driving motor 1 . The output shaft of the drive motor 1 is a hollow shaft and is sleeved on the drive shaft 8 . The coaxial reducer and the drive motor 1 share the drive shaft 8, housing and oil cooling system. Both ends of the drive shaft 8 are connected to drive wheels 10 .

[0025] Transmission ratio i of the coaxial reducer = first-stage speed ratio multiplied by second-stage speed ratio. The coaxial reducer includes a coaxial intermediate shaft gear 4 and a differential input gear 5, the intermediate shaft gear 4 is connected to the output shaft of the drive motor 1 through the drive motor output shaft gear 3, and the differentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com