a centrifuge

A centrifuge and centrifuge mechanism technology, applied in the field of centrifuges, can solve the problems of hazardous operation and trouble for medical staff, and achieve the effect of shortening the operation time and reducing the workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

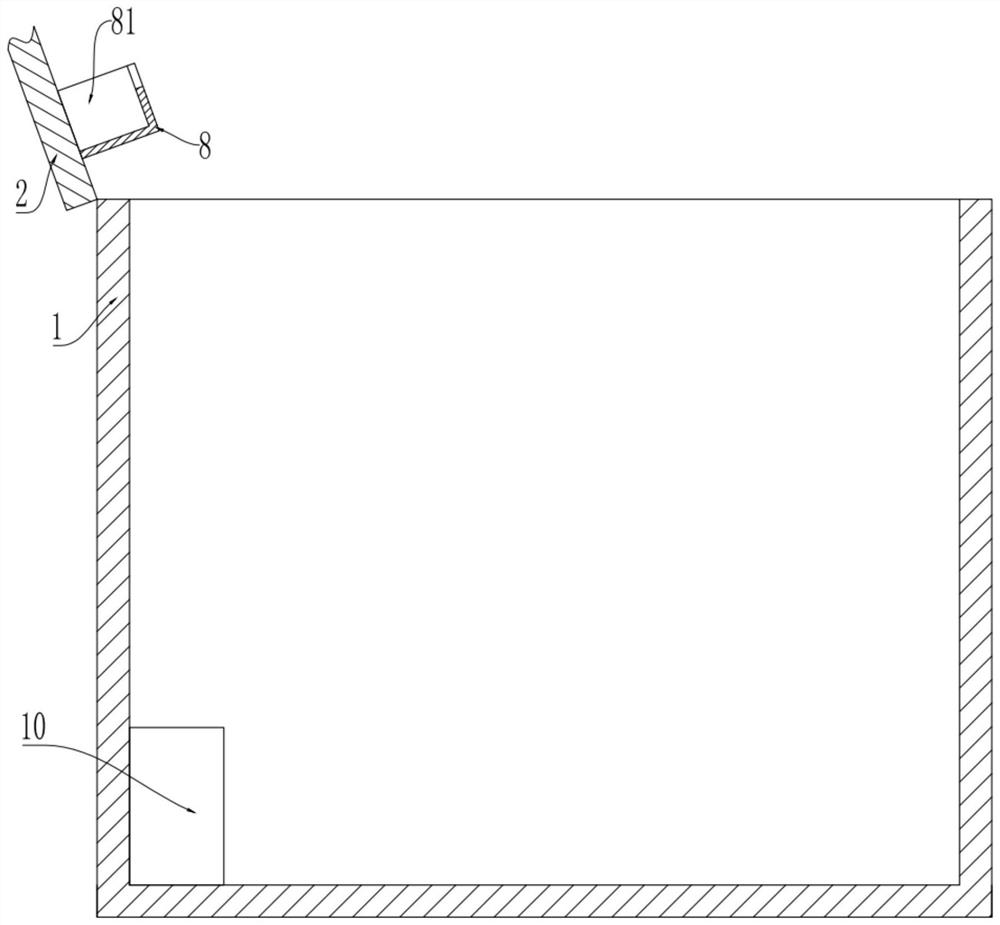

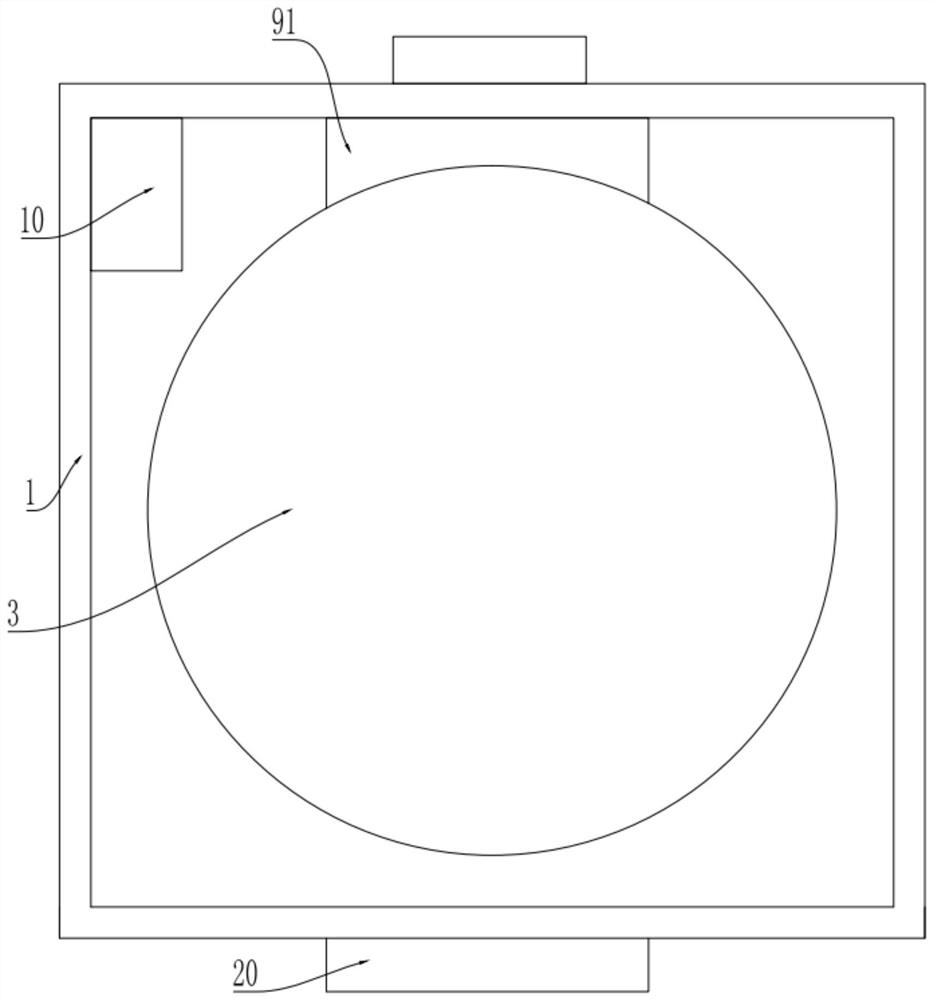

[0040] Embodiment one is basically as attached Figure 1 to Figure 9 Shown:

[0041] combine Figure 1 to Figure 4, a centrifuge, including a housing 1, a cover 2, a centrifugal mechanism 3 located in the housing 1, a holding mechanism, a cover opening mechanism and a negative pressure mechanism 91, the cover 2 forms a closed after the housing 1 is closed Space, the cover body 2 is rotatably connected to the casing 1, the cover body 2 covers the casing 1, the centrifugal mechanism 3 includes a first driver 31, a placement frame 32 and a turntable 33, and the first driver 31 is fixedly connected to the bottom of the casing 1 , the first driver 31 adopts a servo motor, the bottom of the turntable 33 is integrally formed with a vertical shaft 331, the shaft 331 is fixedly connected to the first driver 31, the first driver 31 drives the turntable 33 to rotate, and the placement frame 32 is connected to the turntable 33 in rotation, The placement racks 32 are evenly distributed i...

Embodiment 2

[0058] Embodiment two is basically as attached Figure 10 As shown, embodiment two has carried out following improvement on the basis of embodiment one: between negative pressure machine 91 and negative pressure pipe 92, also be fixedly connected with disinfection tube 30, photocatalyst filter screen 40 and ultraviolet disinfection are installed in the disinfection tube 30 The lamp 50 and the photocatalyst filter screen 40 are V-shaped.

[0059] The specific implementation process is as follows:

[0060] After the negative pressure machine 91 sucks the aerosol out of the housing 1 through the negative pressure tube 92, the aerosol first enters the disinfection tube 30, and the photocatalyst filter screen 40 and the ultraviolet disinfection lamp in the disinfection tube 30 realize air purification. The disinfection and sterilization of the sol ensures the cleanliness of the gas discharged through the negative pressure machine 91.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com