Low-noise atomization cup convenient for dosing and air intake

A low-noise, atomizing cup technology, applied in the field of medical nebulizers, can solve the problems of reduced air intake, reduced treatment effect, patient anxiety, rejection, panic, etc., to achieve good noise reduction effect, reliable positioning, and increased air intake Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

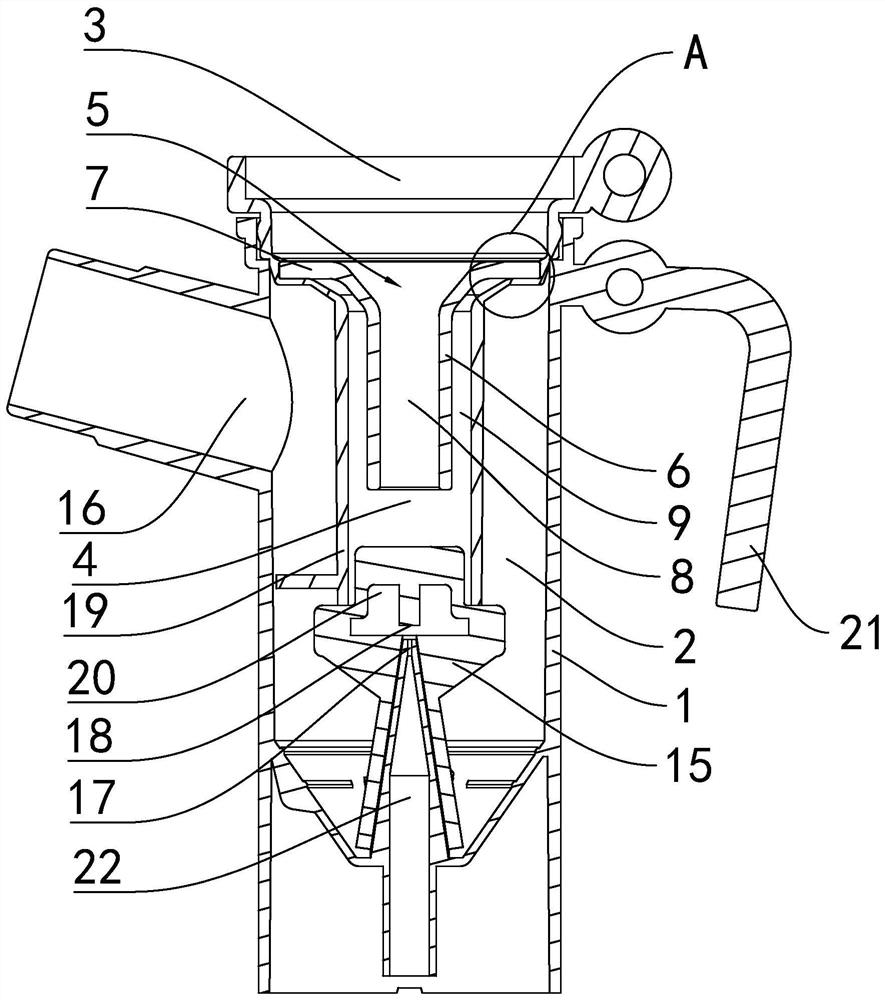

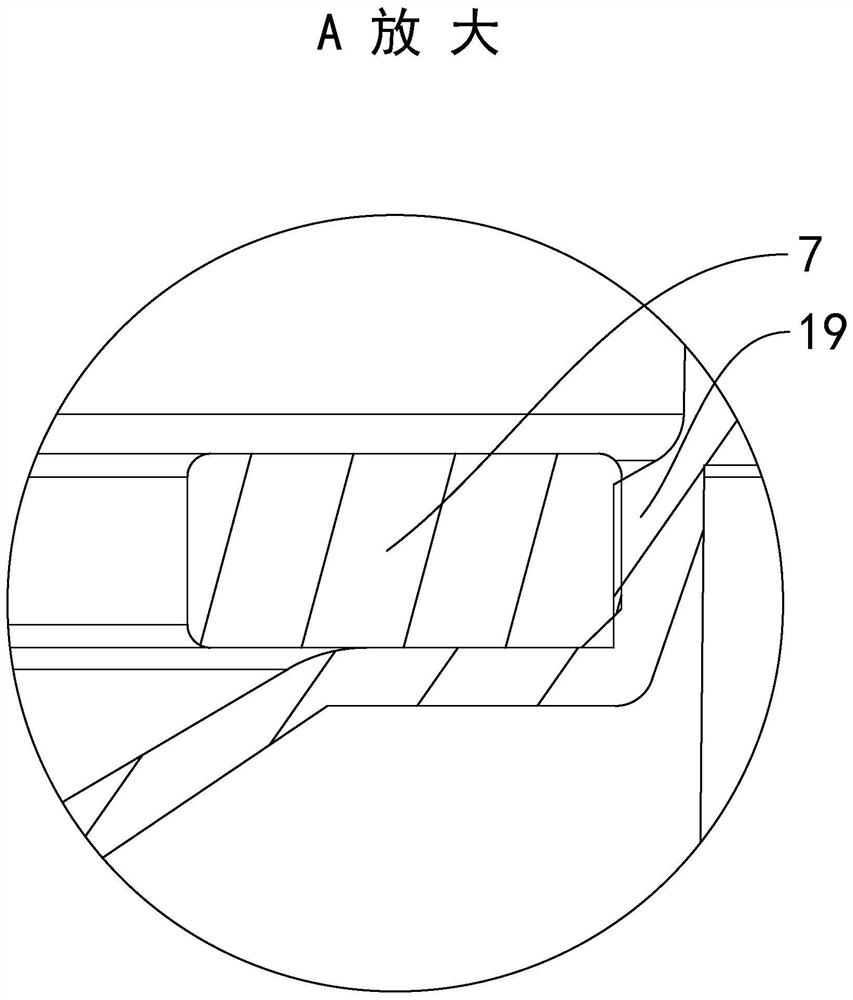

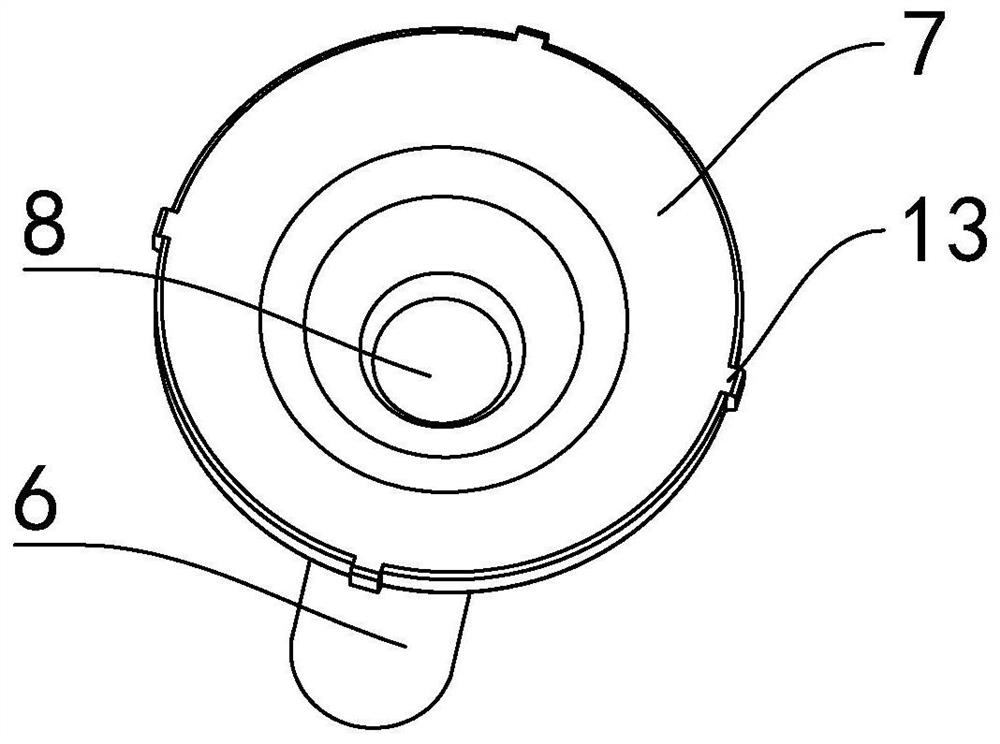

[0061] Embodiment one: see attached figure 1 to attach Figure 4 , and attached Figure 11 to attach Figure 13 , a low-noise atomizing cup convenient for dosing and air intake, the atomizing cup includes a cup shell 1, an inner cup 19 and a cup core 15;

[0062] as attached figure 1 And attached Figure 13 As shown, the cup shell 1 has a chamber 2, the upper end of the cup shell 1 is an opening 3 open upward, and the side wall of the cup shell 1 is provided with a mist outlet connecting the interior of the chamber 2 and the exterior of the chamber 2 16. There is also a handle 21 on the side wall of the cup shell 1. The bottom of the cup shell is provided with an air injection hole 22 whose inner diameter gradually decreases from bottom to top. The air injection hole 22 extends out of the cavity 2 and is connected with compressed air. It is conical, and the tip of the cone extends into the cavity 2 to form a jet port 17, and the jet port 17 is arranged upward;

[0063] T...

Embodiment 2

[0072] Embodiment two: see attached Figure 5 to attach Figure 7 , the difference between embodiment two and embodiment one is:

[0073] The muffler cavity 9 is provided with a spiral rib 10 surrounding the outer wall of the conduit part 6, and the support part 7 is provided with an air inlet 12 through its ring, and one end of the air inlet is connected to the outside of the cup shell 1, and the other end is connected to the outside of the cup shell 1. communicate with the chamber 2 through the sound-absorbing chamber 9;

[0074] In the installed state, viewed along the up and down direction, the width of the spiral rib 10 is equal to the cross-sectional ring width of the sound-absorbing chamber 9, so that the spiral rib 10 is set in the sound-absorbing chamber 9, and the noise will be reduced when it propagates in the sound-absorbing chamber 9 Blocked by the spiral ribs 10, the noise is further weakened, and the support portion 7 can open air intake holes 12 to further in...

Embodiment 3

[0076] Embodiment three: see attached Figure 8 to attach Figure 10 , the difference between embodiment three and embodiment one is:

[0077] A plurality of sieve holes 11 are penetrated in the pipe wall of the conduit part 6 along the vertical direction, and the plurality of sieve holes 11 are arranged around the pipe 8 and separated between the conduit part 6 and the channel 4 to form the muffler cavity 9 ;

[0078] In the installed state, there is a clearance fit between the pipe wall of the conduit part 6 and the inner wall of the passage 4, and the gap width of the gap is much smaller than the ring section ring width of the muffler chamber 9 in Embodiment 1, so that The muffler chamber 9 formed by the screen holes 11 in the third embodiment replaces the muffler chamber 9 of the annular cavity structure, and the structure arranged around the pipe 8 by the screen holes 11 is similar to a honeycomb structure, and its narrow cross-section can reflect noise and weaken its e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com