Non-return valve, in particular for a refrigeration or heat circuit

A technology of heating circuit and check valve, which is applied in the direction of control valves, refrigerators, refrigeration components, etc., can solve the problems of increased leakage rate, etc., and achieve the effects of improved reset force, fast closing process, simple layout and guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

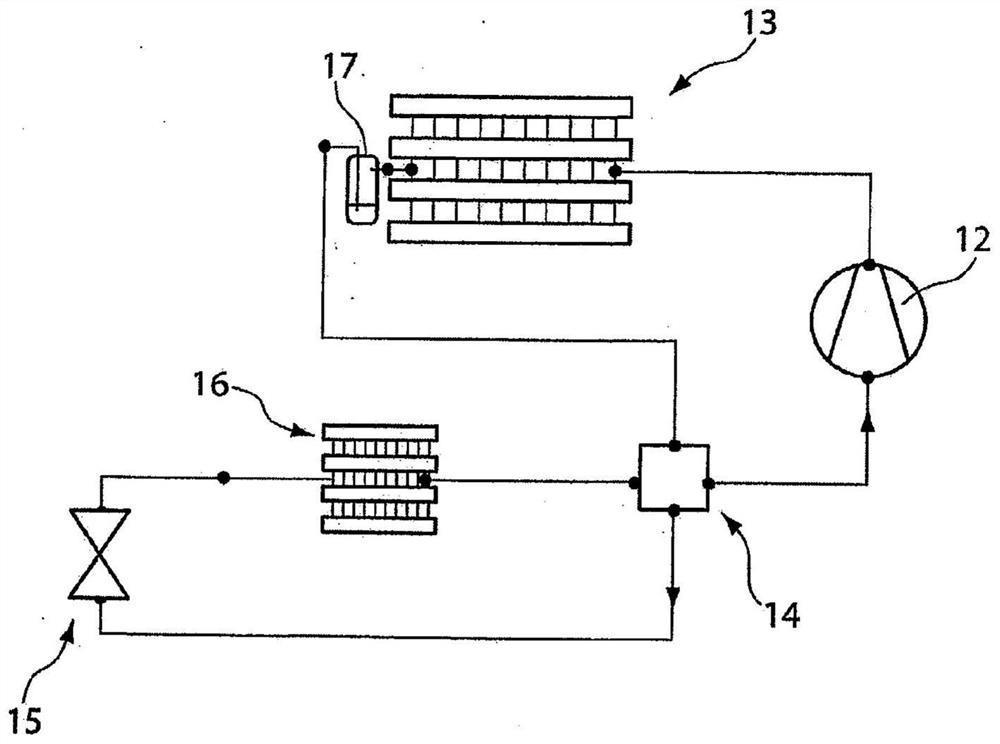

[0053] figure 1 In particular, the conventional structure of a cooling or heating circuit 11 of an air-conditioning system, which is preferably used in a motor vehicle, is shown. Refrigerant is compressed in compressor 12 . The refrigerant can be, for example, R134A, R1234yf or CO 2 . The compressed refrigerant is supplied to the condenser 13, wherein heat exchange occurs between the compressed refrigerant and the surrounding environment in order to cool the refrigerant. An accumulator 17 or collector can be provided downstream of the condenser 13 in order to separate the refrigerant in the gaseous and liquid phases and simultaneously collect the liquid refrigerant. Refrigerant leaving the condenser 13 or the accumulator 17 reaches the internal heat exchanger 14 . An expansion valve 15 is arranged between the internal heat exchanger 14 and the heat exchanger 16 . The mass flow of the cooling or heating circuit 11 is regulated via the expansion valve 15 as a function of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com