Sunshine-proof self-heat-dissipation bridge

A self-cooling, bridge technology, applied in electrical components and other directions, can solve the problem of difficult to effectively dissipate heat, and achieve a good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

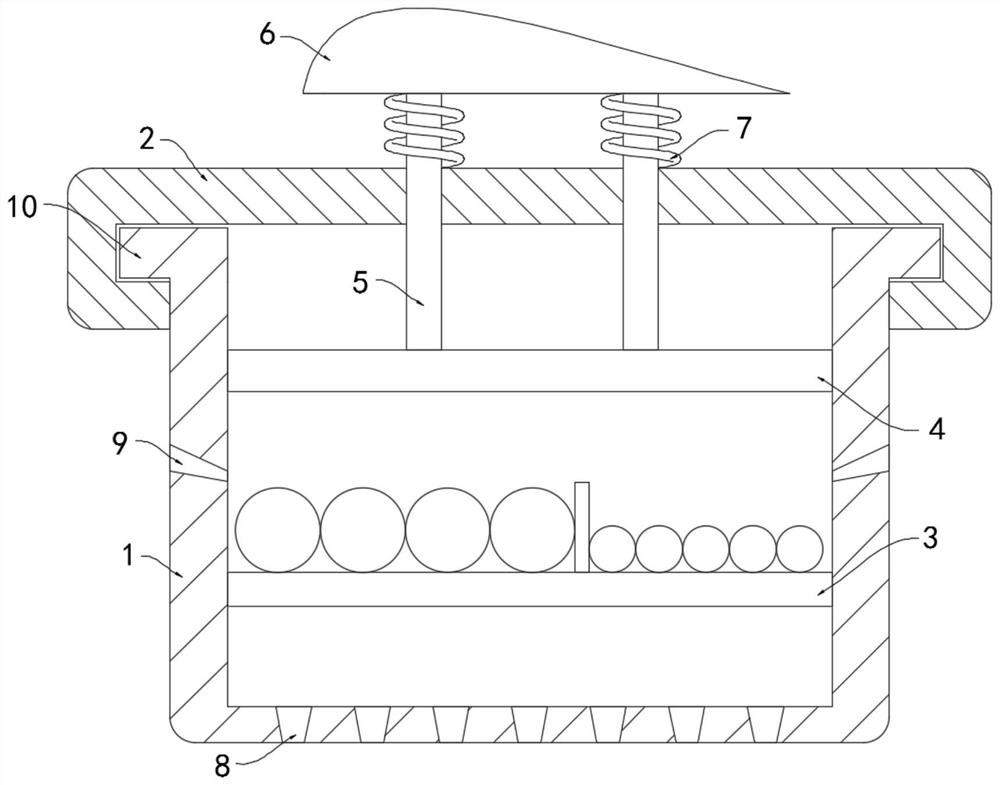

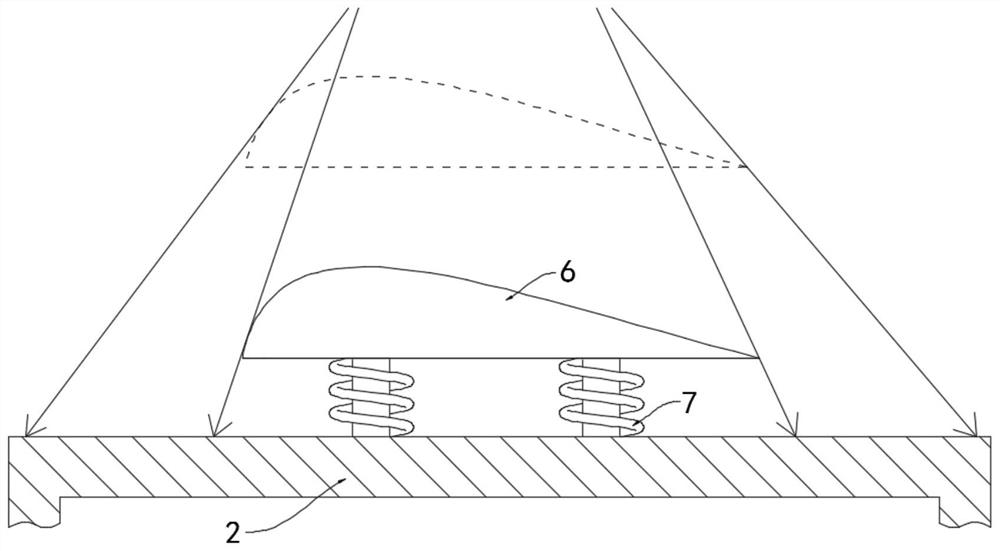

[0022] Such as Figure 1-2 As shown, a sun-proof self-radiating bridge includes a bracket groove 1. It is worth mentioning that the side walls on both sides of the bracket groove 1 extend outward to form a fixing strip 10, and the cross-section of the top cover 2 is C-shaped, which can strengthen the bracket. The connection between the slot 1 and the top cover, the upper end of the bracket slot 1 is detachably connected with the top cover 2 .

[0023] A horizontally arranged bearing plate 3 is fixedly connected to the bracket groove 1, and a horizontally arranged lifting plate 4 is arranged on the upper end of the bearing plate 3. The lifting plate 4 shown is slidingly connected to the inner side wall of the bracket groove 1, and the upper side wall of the lifting plate 4 is fixedly connected with a A plurality of connecting rods 5 are arranged vertically, and the other ends of the connecting rods 5 extend to the upper end of the top cover 2 and are fixedly connected with a wi...

Embodiment 2

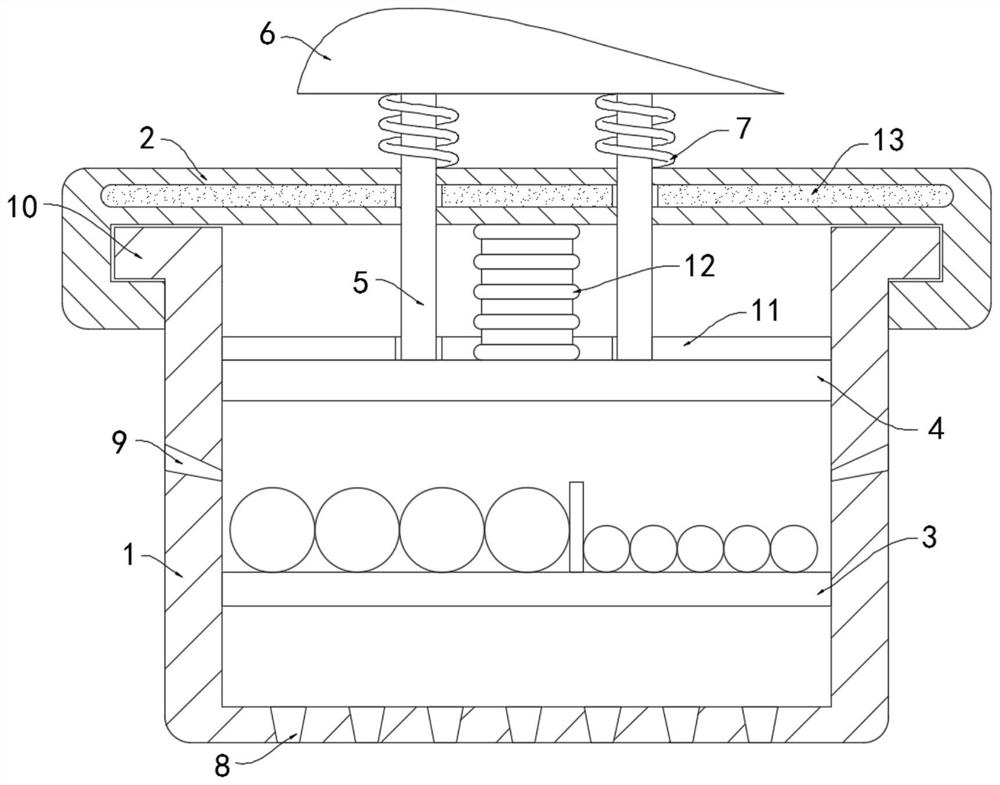

[0031] Such as image 3 As shown, the difference between the present embodiment and Embodiment 1 is that a horizontal storage bag 11 is fixedly connected to the upper side wall of the lifting plate 4, and a corrugated corrugated connection with the storage bag 11 is fixedly connected between the lifting plate 4 and the top cover 2. The tube 12, the storage bag 11 and the bellows 12 are all transparent and contain silver bromide powder inside.

[0032] It is worth mentioning that there is a storage chamber 13 inside the top cover 2, and the storage chamber 13 is filled with paraffin wax. When the paraffin wax is in a solid state, it is opaque, and after melting, it will liquefy into a transparent liquid. After melting, the light can be irradiated into the storage bag 11, that is, it will start when both the temperature and the light are met, which can effectively prevent the interference of other light.

[0033] In this embodiment, strong sunlight shines on the top cover 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com