Laser cladding repairing method for abrasion of circular arc curved surface of cam of airplane control system

A laser cladding, cam arc technology, applied in the coating, metal material coating process and other directions, can solve the problem of cam arc surface wear repair technology is still blank and other problems, to improve cam quality, process safety and reliability, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

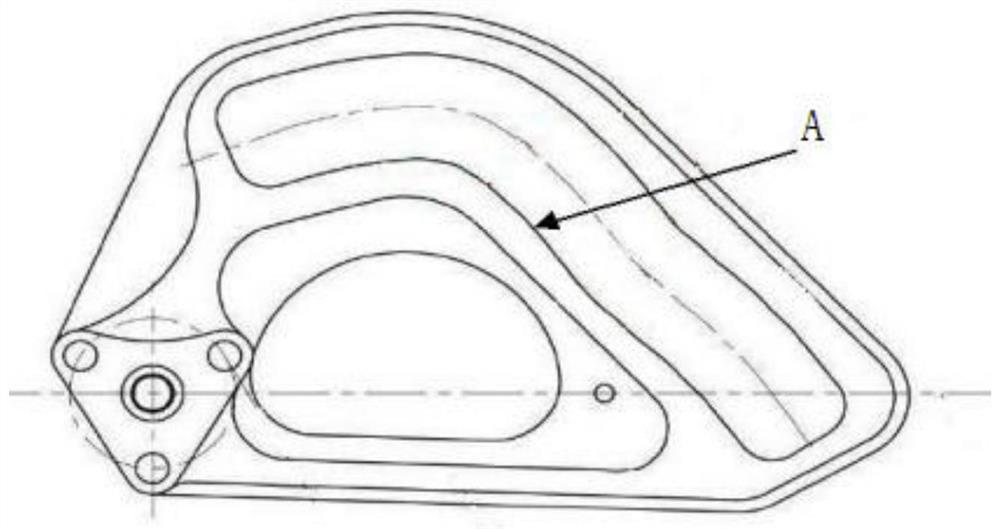

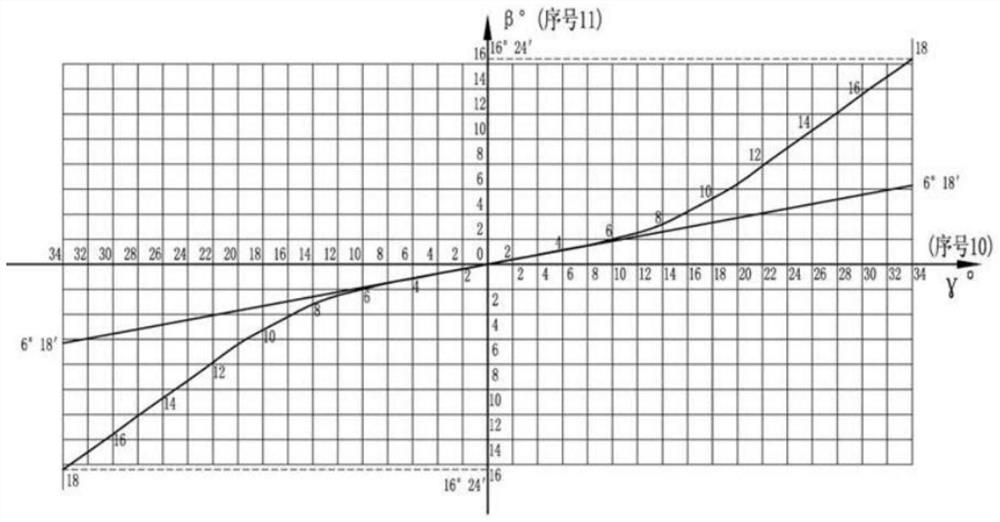

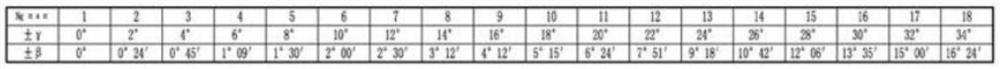

[0033] like figure 1 and figure 2 As shown, a laser cladding repair method for the wear and tear of the cam arc surface of the aircraft control system, the specific steps are as follows:

[0034] S1: Inspection of damage distribution: measure the size, distribution and manifestation of defects in the damaged part, determine the damaged material that needs to be removed by grinding, mark the repair area, and mark the amount of wear at the same time;

[0035] S2: Repair design: The main failure mode of parts is wear, which is mainly caused by normal wear and tear during use. Since the damage area is small and relatively scattered, the incremental size of the repair is relatively thin. Laser cladding technology is planned to be used for parts. carry out partial repairs;

[0036] S3: Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com